On Tuesday, May 23, the Manufacturing@MIT Working Group hosted its second annual symposium in Wong Auditorium, titled “Charting the Future of Production in a Time of Shifting Globalization.”

Speakers covered topics including the history of labor markets, the future of digital production, global supply chains, China’s role, and effective regional initiatives, along with deep dives in two industries: biomanufacturing and semiconductor manufacturing.

Strengthening manufacturing in the United States

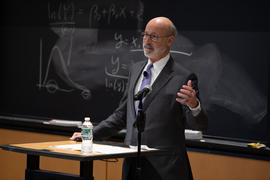

Opening the first session, Suzanne Berger, MIT Institute Professor of Political Science, argued that it’s time for America to make things again, not in the way that led to the decline of the Rust Belt, but using automation and new tools that will allow the country to be a leader in innovation. “It’s great to be talking about manufacturing at this point at MIT,” Berger said. “There’s really a new burst of energy and enthusiasm that we see across the campus … What’s driving this interest is what we all see as a moment of unique opportunity to create a new American production system.”

Sir Michael Gregory, professor and founding director of the Institute for Manufacturing at the University of Cambridge, England, argued that governments need to play a strong role in boosting manufacturing. “People say that government shouldn’t choose winners and losers,” he said. “I say that government shouldn’t pick losers.” He and panelists Liz Reynolds, an MIT lecturer and partner in the investment firm Unless, and Bill Bonvillian of MIT, made the point that the re-emergence of industrial policy will promote technology innovation and scaling, and require major investments in workforce development and sustainability.

Strengthening America’s industrial base requires states to play a leading role. Massachusetts Secretary of Economic Development Yvonne Hao, in a session with MIT’s Ben Armstrong and MassVenture Development Manager Sienna Leis, outlined the commonwealth’s strengths, including its highly skilled workforce, drive for clean energy solutions, and entrepreneurial and collaborative mindset. “We have so many strengths, so many good things happening, such an amazing team,” said Hao. “We have to work together as Team Massachusetts to do the work [to lead in advanced manufacturing] right now.”

Creating a strong industrial base also means fostering new and growing companies. In a session on scaling digital production, panelists Nate Tedford PhD ’06 of Ginkgo Bioworks, Martin Feldmann MEng ’14 of VulcanForms, and Antonin Bacot MBA ’18 of Topologic discussed their technologies and visions, as well as the challenges they faced scaling their organizations and becoming commercially successful. “We have to, with absolute brute force, build up our hardware process innovation and product innovation ecosystem,” said Feldmann. “Otherwise, we will fade into irrelevance, and I’m genuinely scared of that.”

Companies can only grow if they have access to workers. In his talk, “A Perspective on the Labor Market for Manufacturing,” MIT Ford Professor of Economics David Autor said labor scarcity results from low population growth, restrictive immigration, and large-scale retirement. While manufacturing may not pay wages comparable to what some service jobs do on a dollars-per-hour basis, on an annual basis manufacturing often wins out. “The predictability of shift work lets workers plan their family lives outside of work,” he said. “These are messages we need to continue to communicate.” Jobs for the Future CEO Maria Flynn argued that the United States needs an ARPA-L — a research institution focused on labor that could address issues like the ones Autor raised.

The manufacturing workforce

One of the challenges the United States faces is developing effective advanced manufacturing training programs, and then recruiting students to enroll in them. Peter Goodman, who led three of the symposium sessions and is a New York Times global economics correspondent, asked about manufacturing workforce challenges. Bonvillian responded that while the U.S. leads in teaching scientists and engineers at the undergraduate and graduate levels, the nation is at best adequate in pK-12 STEM education, while being weak in front-line workforce preparation and training. “We lack broad-based apprenticeship opportunities and programs for up-skilling the incumbent workforce,” pointing the way for policy leaders.

While speakers agreed that students needed to become more aware of manufacturing careers, Tom Kurfess, chief manufacturing officer at Georgia Tech, said that he’s seen students get excited about robots in automotive assembly plants in the southeast. “Everyone loves robots — we just have to get the word out more broadly.” He said earn-and-learn models work well. MIT lecturer and researcher John Liu, who led the panel discussion “Rebuilding the Manufacturing Workforce,” noted that the career website Handshake listed the top 10 “buzziest” companies for Gen Z, and that they included the manufacturing firms Raytheon ranked first, Nike second, Toyota third, Lockheed Martin fourth, and Boeing eighth.

Manufacturing@MIT

The symposium was organized by the Manufacturing@MIT Working Group, which is co-directed by Professor John Hart (mechanical engineering) and Berger. Since early 2022, this group, which includes faculty from across campus, has been working to unite MIT’s manufacturing community, and sees the opportunity to launch a major new initiative in manufacturing at MIT. This would tie together efforts spanning engineering, social and management sciences, and workforce development, and build new programs and partnerships within and beyond MIT.

MIT’s contributions to modern manufacturing include the development of early CNC machine tools in the 1950s and 3D printers in the early 1990s; key advances in materials, automation, and systems engineering; and world-class entrepreneurship and industry leadership by its alumni. MIT has also shaped policy and technology perspectives on manufacturing domestically and abroad through such studies as Made in America (1990), Production in the Innovation Economy (2010), Making in America (2013), and The Work of The Future (2022).

Moreover, with recent lessons about the fragility of supply chains, as well as the social disruption to the working class and people of color from the decline in U.S. manufacturing, the federal government is more focused on America’s manufacturing future than it has been in decades. “Manufacturing is vital to our economic and national security, and we must scale advanced manufacturing systems hand-in-hand with sustainability,” said Hart. “We’ve seen a tremendous interest in manufacturing across MIT, including at today’s symposium, and we are excited to help shape the future of production through technology innovation, partnership with industry, and engagement with the public sector.”

Other highlights

- Ahmad Bahai, chief technology officer of Texas Instruments, along with Chris Miller, Tufts University professor of international history and author of “Chip War,” discussed the future of semiconductor manufacturing in the light of CHIPS Act funding, international competition, and new technology advances.

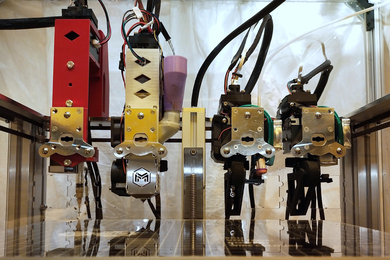

- Chris Love, MIT professor of chemical engineering, explained the tremendous potential for biomanufacturing, and highlighted the efforts of Sunflower Therapeutics (a startup he co-founded) to build cost-effective, modular bioreactors for protein production.

- Yasheng Huang, professor in the MIT Sloan School of Management, spoke about the challenges both China and the United States will face as manufacturers seek to diversify their supply chains beyond China.

- Jason Rathje, director of the U.S. Department of Defense’s Office of Strategic Capital; Susan Schofer, partner, SOSV/HAX; and Anthony Manzo, executive vice president of corporate development at Re:Build Manufacturing, spoke about the importance of investing in industrial transformation, where the initial capital equipment costs are high and scale-up can take years.

- Janet Godsell, professor and dean of the School of Business and Economics at Loughborough University, and Elsa Olivetti, MIT professor of materials science and engineering and co-director of the MIT Climate and Sustainability Consortium, discussed shifting supply chains and the importance of moving to a circular economy.

“The symposium crystallized a new generation of a manufacturing community that has been at MIT for a long time,” said David Mindell, the Dibner Professor of the History of Engineering and Manufacturing. “No other university brings together such diverse technical talent with the analytical and policy expertise we find at MIT, with a decades-long track record of innovation and impact. Every speaker addressed key issues from unique angles: the need to revitalize production ecosystems in the face of multiple challenges.”

The Association of Manufacturing Technology, the Department of Defense Manufacturing Technology Office, Schmidt Futures, and the Department of Mechanical Engineering all partnered with Manufacturing@MIT to support the symposium.