As the Covid-19 pandemic began to spread, it became clear that ventilators would be a crucial part of the medical response in order to keep patients breathing as they fought the disease.

In January, Philips Respironics, a major manufacturer of mechanical ventilators, put together an engineering response team to rapidly scale production and meet the needs of hospitals to deploy this lifesaving technology. Erwin Franz, a master’s student in MIT’s System Design and Management (SDM) program and senior research and development engineer at Philips, was selected to join this team of engineers and developers. He quickly realized he could use lessons from SDM’s core class to help his team meet this challenge.

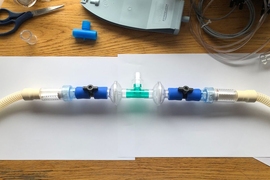

One of the actions Philips took in response to the critical hospital ventilation shortage was to design the Philips Respironics E30, an emergency use ventilator. Erwin described this as a platform strategy problem, similar to those taught by Bruce Cameron in the SDM core. The Philips Respironics E30 ventilator was built from the company’s trusted bilevel positive airway pressure (BiPAP) platform to be used as an emergency-use ventilator during the current Covid-19 pandemic. It was intended for mass production, with fewer — though still present — alarm and monitoring capabilities, as well as different pressure settings than traditional hospital ventilators. It is approved for invasive and non-invasive ventilation during the current pandemic and must be disposed of or returned following the pandemic.

The response team is also handling an influx of companies approaching Philips to partner by scaling production and increasing the number of ventilators and similar machines that can be built at the same time. Erwin is using his research and development background to work on part of a hospital-grade ventilator at home, figuring out how to get it to interface with these new partners’ technologies. Once he completes this work, partner companies will be able to use his work for calibrating and producing new ventilators safely and quickly.

Before joining SDM, Erwin was part of the test tools engineering team working on the reliability testing of a newly developed mechanical ventilator. His background in electronics and hardware development led him to join Philips to expand his engineering background into the medical device development field. However, he felt that he needed to sharpen his leadership skills and to gain tools for more effective management of his technical team, which brought him to SDM. He says he is already applying the system architecture, system engineering, and project management skills taught in the core class to his work. “When I started documenting things differently, using the concepts that we learned with [Ed] Crawley and [Bruce] Cameron, that was groundbreaking. The learning curve for people who were new to the team to start contributing to what we were doing was reduced dramatically, because the documentation of how to show the architecture of the system was transparent to them.”

As the waves of Covid-19 infection peak and plateau, Erwin says he is not worried about shortages of medical equipment; he is confident that the work he is doing with Philips is generating the infrastructure that doctors need. He also says he is rethinking his own trajectory in the master’s program at SDM. He is now considering taking more classes on modeling, such as 15.871 (Introduction to Systems Dynamics I) and IDS.131 (Statistics, Computation and Applications), so that he can apply systems thinking to strategy, organizational change, and policy design.