Even if you are among the half of all Americans who take dietary supplements — a $30 billion industry — the idea of swallowing a handful of them daily probably makes you cringe. Evaluating your deficiencies, adjusting to seasonal needs, and adapting to life and body changes all take time and energy.

Now a group of MIT alumni and students has found an easy way to do most of that in just one pill.

Multiply Labs was started two years ago when Fred Parietti PhD ’16 and Alice Melocchi, a visiting scholar at the MIT-Novartis Center for Continuous Manufacturing in the MIT Department of Chemical Engineering, began to discuss how they could create smaller batches of pharmaceuticals in a faster way.

“I was talking with a friend of mine and she was taking more than 10 pills a day,” Parietti says. “And she told me: ‘Look, these could change my life in terms of supplements. Having a single pill would be a game changer.’ This [made me realize] it’s not just me, and there are people that take even more than me.”

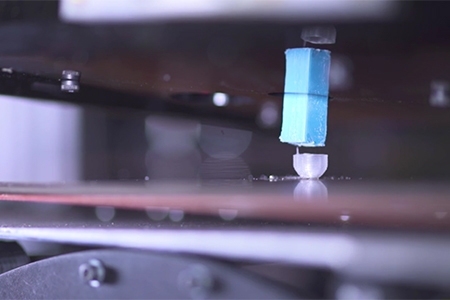

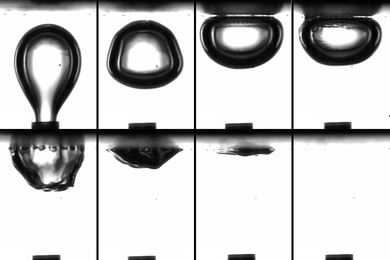

Parietti was using 3-D printing for robotics research and saw a natural fit for the tool. He and Melocchi spent the next two years pursuing the project, focused on confirming that using 3-D printing allowed for the same time-of-release profile achieved with a normal large-batch printed capsule.

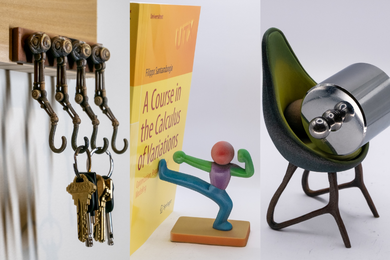

“One of our most popular combinations is a morning release of vitamin D and omega-3 and then later in the day, caffeine,” says Tiffany Kuo MBA ’16. “The fact that caffeine is added to the supplement and released later in the day is something a mass-produced pill cannot do.”

Kuo and another student in the MIT Sloan School of Management, Joe Wilson, joined the co-founders in the second year to help with market research and commercialization of the product.

“We found a lot of young professionals care about health and fitness but don’t have time to devote to their own well-being,” Kuo says. “Because we’re using 3-D printing robotics to manufacture in smaller batches rather than larger batches, it allows us to do personalization and allows us to get different formulations out and printed faster.”

So how do they customize each pill to their customers? Multiply Labs partnered with a nutritionist to develop a tool that takes into account height, sex, weight, health goals, and current diet to identify gaps in nutrition. They also have plans down the road to incorporate blood tests for better knowledge of individualized deficiencies. The pill is the size of an Omega-3 capsule and includes only the supplements and amounts deemed necessary for the individual user. The personalized supplements are delivered every two weeks, allowing them to be adjusted to the user's feedback and other variations such as changes in weather.

The company will officially launch this spring and has started taking preorders for supplements. The team not only got its start at MIT, they also received seed funding through the MIT Sandbox Innovation Fund Program, allowing them to set up a headquarters in San Francisco and devote themselves full-time to the endeavor. They are currently outfitting their recently-acquired warehouse to meet U.S. Food and Drug Administration standards for manufacturing practices.