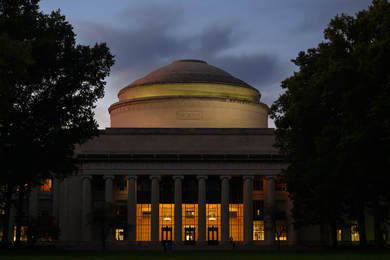

A spectacular show has been going on outside the windows of central-campus buildings all spring. An enormous steel structure has been growing — piece by piece, and bolt by bolt — out of a giant hole in the ground formerly occupied by Building 12. At a March 24 “tool talk” information session for the MIT community on the construction of MIT.nano, representatives from MIT Facilities and the contractors who are building the new 200,000 square foot nanoscale characterization and fabrication facility gave an overview not only of where things stand with the project, but how they got stood up.

“In our structural-steel erection progress log, we’ve been averaging around 23 tons per day,” said Peter Johnson of Turner Construction. “We’re putting up 2,101 tons total, and we’re 22 percent complete.”

On day 469 of the 1,000 days of construction for the project, about 75 percent of the first level was complete, and a quarter of the level 3 cleanroom was installed down to the floor decking. The framing for the entire structure, which will reach a final height of 90 feet above grade, is scheduled to be complete by late May. To get there, Johnson and others have spent years organizing and refining a minutely detailed project plan that links engineering design and fabrication, and the installation process. They have had to map out construction logistics on an hour-to-hour, and foot-by-foot basis. It all must be calibrated to unfold within specific timelines and within the tight confines of MIT.nano’s central campus location. “There’s not a lot of space when it comes to material handling and the movement of workers,” Johnson noted.

Decisions about cranes, Johnson said, were particularly critical. “While we could have used a single crane to reach the entire footprint, it was too slow. We have a several thousand line item project schedule with hundreds of steel-related tasks,” Johnson explained. “So having two cranes for a shorter period of time made the job more efficient.”

The first crane was erected during the excavation phase, so workers could use it to lower concrete and rebar into the excavated hole for elements of the foundation. The next crane arrived just prior to steel installation. Positioned strategically in locations that do not block truck routes, the cranes hoist pre-fabricated, specially packaged bundles of steel into the specific locations where they will be needed for construction. Within these packages, each piece has a number that corresponds to its function and placement, and each one has been specifically manufactured for its location, with features like pre-drilled holes to accommodate plumbing and electrical connections. (“So someone knows where the number goes, and that side A connects to side B?” asked Vladimir Bulovic, the faculty lead on the design and construction of MIT.nano. “Just like my Ikea furniture, but bigger.” The construction experts did not dismiss the comparison.)

Working with Ontario-based steel fabricator, Canatal, Johnson and his colleagues at Turner developed a four-dimensional plan for steel engineering, delivery, and installation. “We went through a painstaking process to maximize efficiency of this sequence,” says Johnson. “This allows us to avoid times when a crane is down because it’s waiting” for a delivery of steel.

As the structure grows, engineers continuously monitor the basement walls and foundation of the structure with inclinometers, a seismograph, and a three-dimensional laser scanner to gauge how they are responding to the additional weight of the steel. The corner braces in the building’s 50-foot-deep excavation that counteract pressure coming from outside the walls will be removed after the steel is finished and concrete is poured on the building’s first floor. “The building is performing the way we expected it to,” said Richard Amster, director of campus construction.