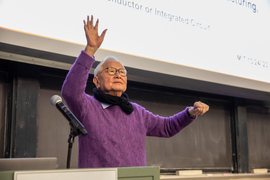

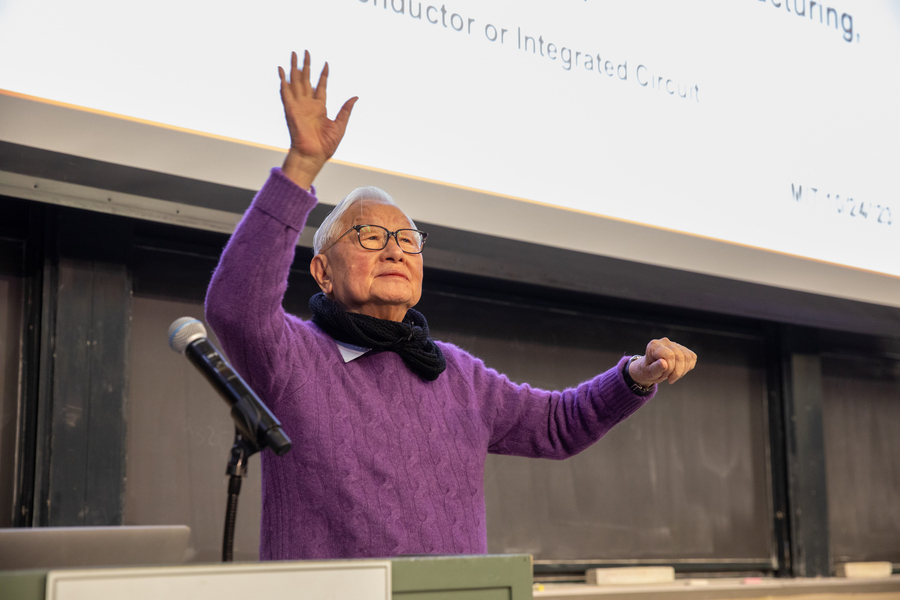

Groundbreaking technologist Morris Chang ’52, SM ’53 discussed the key elements behind Taiwan’s long-term ascendancy in semiconductor manufacturing, while speaking to a large campus audience in an MIT talk on Tuesday.

Chang is the influential founder and former longtime head of TSMC, the Taiwan Semiconductor Manufacturing Company, which has become the world’s leading microchip maker. Chang started the firm in 1987, and since then it has helped reshape the industry by making Taiwan a crucial center of production and by focusing on manufacturing while chip design occurs elsewhere.

In his remarks, Chang, whose career spans the history of the semiconductor industry, gave a broad overview of the development of chip manufacturing, then focused on some of the factors that have helped TSMC and Taiwan thrive. In his view, this includes a healthy supply of talent, in the form of engineers and other technical employees willing to work in manufacturing; low turnover of employees; a geographical concentration of industry manufacturing in Taiwan; and the “experience curve theory,” in which accumulated manufacturing experience leads to lower production costs.

“Why is TSMC successful in Taiwan?” asked Chang. “Because TSMC also gets good, well-trained technicians, and even well-trained operators from a lot of trade schools in Taiwan. … Their students aspire to make a good living as technicians.”

Chang also argued that the process of learning by doing, in which manufacturers can reduce costs by improving their processes, is predicated on having production centered in one place, with connectivity among workers in common conditions.

“It works, the learning curve, the experience curve, it works only when you have a common location,” Chang said. “Learning is local.”

More broadly, Chang noted, prominence in semiconductor manufacturing “seems to be related to the status of economic development of that country. Frankly, the advantages that Taiwan enjoys today … were enjoyed by the U.S. in the ’50s and ’60s.” Decades in the future, he suggested, there could be a rise in semiconductor activity in India, Vietnam, or Indonesia, depending on the way circumstances evolve.

Chang’s talk, “Lessons of a Life in Semiconductor Manufacturing, from Texas to Taiwan,” was delivered to a capacity audience of more than 425 people in MIT’s Room 10-250. The event was part of the Manufacturing@MIT Distinguished Speaker Series.

Chang was born in China in 1931, left the country in the late 1940s, and earned his BS and MS in mechanical engineering from MIT. He later received a PhD in Electrical Engineering from Stanford University. Chang entered the semiconductor business by taking a job at Sylvania in the mid-1950s. He moved to Texas Instruments — then a chip-making power — in 1958, rising to industry prominence during a quarter-century tenure there. Chang also became a U.S. citizen in 1962. In the 1980s, he was invited to work on the development of industrial and technology in Taiwan, and soon thereafter launched TSMC. Over time, TSMC has become a juggernaut, sustaining its success and growing to become the world leader in the field.

At Tuesday’s event, Chang was introduced by MIT Provost Cynthia Barnhart, who emphasized the enduring connections he has built at the Institute. Chang is a life member emeritus of the MIT Corporation and has been an important supporter of the Institute. The renovated Building E52, which houses the Department of Economics, the Samberg Conference Center, and offices of the MIT Sloan School of Management, is now the Morris and Sophie Chang Building.

“For MIT, Morris is an extraordinary example of the lasting impact our alumni have on the legacy of innovation at the Institute,” Barnhart said.

At the end of his talk, Chang also briefly discussed geopolitics and chip production. With U.S.-China relations relatively strained, chip manufacturing is one of the areas where they are competing in industrial terms. Meanwhile, the precise nature of China’s policy intentions vis-à-vis Taiwan remain uncertain.

“Without national security, we will lose everything, everything that we value,” Chang said. At the same time, he noted, “By all means, let’s avoid even a Cold War, if we can.”

The event was hosted by the Manufacturing@MIT Working Group, in collaboration with the School of Engineering, the Department of Mechanical Engineering, the Department of Political Science, Leaders for Global Operations, Microsystems Technology Laboratories, the Industrial Performance Center, MIT.nano, Machine Intelligence for Manufacturing and Operations, the Laboratory for Manufacturing and Productivity, and Mission Innovation X.