Chemical engineering does not typically start out as a “hands-on” field of study. Thanks to Bradley Olsen and his new course for MIT freshmen, 10.00 (Molecule Builders), that will change starting in Spring 2016.

“Institute-wide, students are articulating a desire to gain early, hands-on experience,” says Olsen, the Paul M. Cook Associate Professor of Chemical Engineering (ChemE). “This class will do just that, introducing students to engineering design at the molecular level, and giving them a sense of what chemical engineers actually do.”

Citing student surveys in which undergraduates have expressed a desire to make things as early as possible in their time at MIT, and a growing interest in learning about the career possibilities afforded by their course of study, Olsen and his colleagues in ChemE got together and designed a new, foundational subject for Course 10. Drawing on such MIT institutions as the product design classes offered by the Department of Mechanical Engineering and Introduction to Aerospace and Design (known among students as “Build-a-Blimp”) in the Department of Aeronautics and Astronautics, Olsen designed a course that depends on a basic knowledge of chemistry, biology, and physics. Students will learn new ChemE concepts and techniques as they devise solutions to open-ended problems.

“When you want to learn a foreign language, you go abroad for a year,” Olsen says. “You have trouble talking to everybody — that’s motivating. We want to give students experiences that show them they need to learn these things in order to master real-life challenges.”

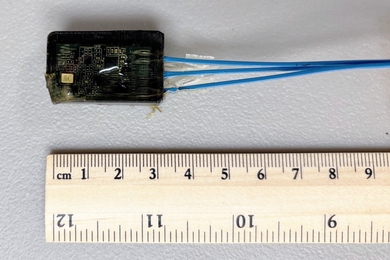

For the first class of Molecule Builders, students will have their choice of three challenges, each offering what Olsen calls a “maker space” in a different chemical engineering domain. One project will involve building a car for a national competition that requires the creation of contained and controllable chemical reactions to power a vehicle a certain distance. Another project asks students to design an organism or enzyme that can yield specific quantities of a desired chemical product. Additional projects under development, including microfluidic manufacture of gel microparticles using 3-D printers and the design of solar water heaters.

Each of these assignments involves “complicated design experiences where students learn about making tradeoffs,” Olsen says. “They may try one design that is hard and more expensive, then a different one that is cheaper but more practical.” Olsen anticipates that freshman “may hit bumps or do things suboptimally, kludging stuff together.” That would be just fine, because “students will say, ‘I could have improved my amazing design if I’d just understood thermodynamics or fluid dynamics better’ — and then they go on to study those areas.”

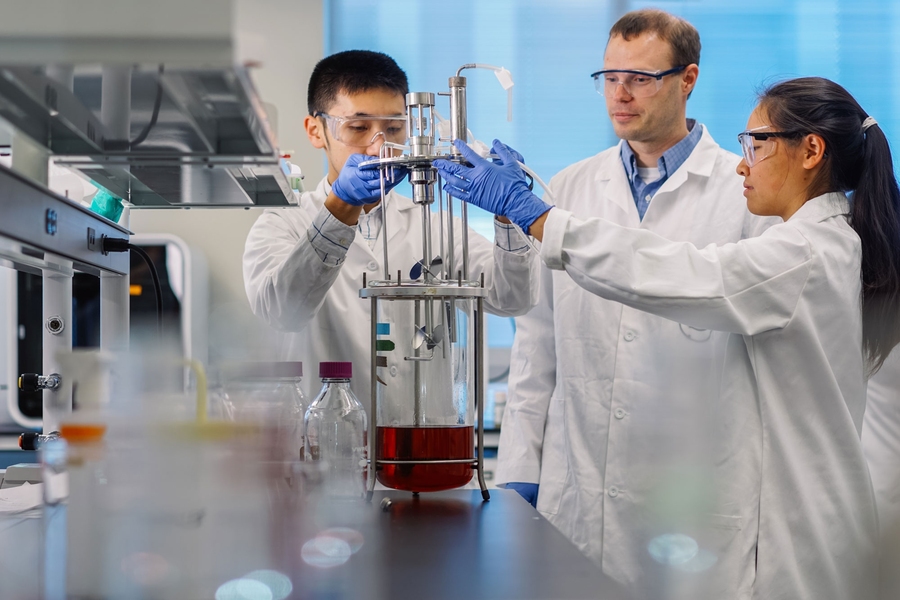

Olsen and Kristala Prather, the Theodore T. Miller Associate Professor of Chemical Engineering, along with a team of teaching assistants, will school 10.00 students not just in basic engineering principles and state-of-the-art ChemE methods, but also in safety practices for managing reactions, synthesizing biological components, and manipulating substances at the molecular level. Learning the discipline’s safety culture is part of the larger lesson Olsen hopes to get across. “We want students exposed not just to doing chemical engineering design, but to what chemical engineers really do in their different occupations and workplaces.”

To that end, 10.00 also includes panels with people from industry talking about their work, and with faculty, graduate students, and undergraduates who will discuss their research. “We want to show the wonderful opportunities that exist in the profession,” Olsen says. “Everything you use that’s ‘a thing’ is made of chemicals, and a lot of chemical engineers are involved in the pathways that get us from chemicals to the final product,” he says.

While Olsen would be gratified if Molecule Builders pointed more MIT students toward chemical engineering careers, in the short term he hopes to generate excitement about MIT’s ChemE major. He thinks 10.00 offers students what they say they want: a safe space to design and make things using sophisticated techniques and tools, and, says Olsen, “a way to live out that 'mens-et-manus' MIT mission.”