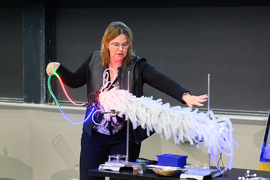

“Can we make tissues that are made from you, for you?” asked Jennifer Lewis ScD ’91 at the 2025 Mildred S. Dresselhaus Lecture, organized by MIT.nano, on Nov. 3. “The grand challenge goal is to create these tissues for therapeutic use and, ultimately, at the whole organ scale.”

Lewis, the Hansjörg Wyss Professor of Biologically Inspired Engineering at Harvard University, is pursuing that challenge through advances in 3D printing. In her talk presented to a combined in-person and virtual audience of over 500 attendees, Lewis shared work from her lab that focuses on enhanced function in 3D printed components for use in soft electronics, robotics, and life sciences.

“How you make a material affects its structure, and it affects its properties,” said Lewis. “This perspective was a light bulb moment for me, to think about 3D printing beyond just prototyping and making shapes, but really being able to control local composition, structure, and properties across multiple scales.”

A trained materials scientist, Lewis reflected on learning to speak the language of biologists when she joined Harvard to start her own lab focused on bioprinting and biological engineering. How does one compare particles and polymers to stem cells and extracellular matrices? A key commonality, she explained, is the need for a material that can be embedded and then erased, leaving behind open channels. To meet this need, Lewis’ lab developed new 3D printing methods, sophisticated printhead designs, and viscoelastic inks — meaning the ink can go back and forth between liquid and solid form.

Displaying a video of a moving robot octopus named Octobot, Lewis showed how her group engineered two sacrificial inks that change from fluid to solid upon either warming or cooling. The concept draws inspiration from nature — plants that dynamically change in response to touch, light, heat, and hydration. For Octobot, Lewis’ team used sacrificial ink and an embedded printing process that enables free-form printing in three dimensions, rather than layer-by-layer, to create a fully soft autonomous robot. An oscillating circuit in the center guides the fuel (hydrogen peroxide), making the arms move up and down as they inflate and deflate.

From robots to whole organ engineering

“How can we leverage shape morphing in tissue engineering?” asked Lewis. “Just like our blood continuously flows through our body, we could have continuous supply of healing.”

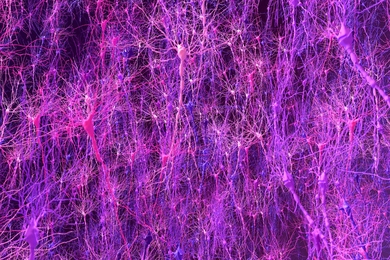

Lewis’ lab is now working on building human tissues, primarily cardiac, kidney, and cerebral tissue, using patient-specific cells. The motivation, Lewis explained, is not only the need for human organs for people with diseases, but the fact that receiving a donated organ means taking immunosuppressants the rest of your life. If, instead, the tissue could be made from your own cells, it would be a stronger match to your own body.

“Just like we did to engineer viscoelastic matrices for embedded printing of functional and structural materials,” said Lewis, “we can take stem cells and then use our sacrificial writing method to write in perfusable vasculature.” The process uses a technique Lewis calls SWIFT — sacrificial writing into functional tissue. Sharing lab results, Lewis showed how the stem cells, differentiated into cardiac building blocks, are initially beating individually, but after being packed into a tighter space that will support SWIFT, these building blocks fuse together and become one tissue that beats synchronously. Then, her team uses a gelatin ink that solidifies or liquefies with temperature changes to print the complex design of human vessels, flushing away the ink to leave behind open lumens. The channel remains open, mimicking a blood vessel network that could have fluid actively, continuously flowing through it. “Where we’re going is to expand this not only to different tissue types, but also building in mechanisms by which we can build multi-scale vasculature,” said Lewis.

Honoring Mildred S. Dresselhaus

In closing, Lewis reflected on Dresselhaus’ positive impact on her own career. “I want to dedicate this [talk] to Millie Dresselhaus,” said Lewis. She pointed to a quote by Millie: “The best thing about having a lady professor on campus is that it tells women students that they can do it, too.” Lewis, who arrived at MIT as a materials science and engineering graduate student in the late 1980s, a time when there were very few women with engineering doctorates, noted that “just seeing someone of her stature was really an inspiration for me. I thank her very much for all that she’s done, for her amazing inspiration both as a student, as a faculty member, and even now, today.”

After the lecture, Lewis was joined by Ritu Raman, the Eugene Bell Career Development Assistant Professor of Tissue Engineering in the MIT Department of Mechanical Engineering, for a question-and-answer session. Their discussion included ideas on 3D printing hardware and software, tissue repair and regeneration, and bioprinting in space.

“Both Mildred Dresselhaus and Jennifer Lewis have made incredible contributions to science and served as inspiring role models to many in the MIT community and beyond, including myself,” said Raman. “In my own career as a tissue engineer, the tools and techniques developed by Professor Lewis and her team have critically informed and enabled the research my lab is pursuing.”

This was the seventh Dresselhaus Lecture, named in honor of the late MIT Institute Professor Mildred Dresselhaus, known to many as the "Queen of Carbon Science.” The annual event honors a significant figure in science and engineering from anywhere in the world whose leadership and impact echo Dresselhaus’ life, accomplishments, and values.

“Professor Lewis exemplifies, in so many ways, the spirit of Millie Dresselhaus,” said MIT.nano Director Vladimir Bulović. “Millie’s groundbreaking work, indeed, is well known; and the groundbreaking work of Professor Lewis in 3D printing and bio-inspired materials continues that legacy.”