Participating in an intensive three-week lab in Yucatán, Mexico, changed how MIT junior Penelope Herrero-Marques views her role as an engineer.

The January trip was the first step in a new partnership between MIT D-Lab and Perkins School for the Blind, a Massachusetts-based national service provider and international nonprofit that strives to make education accessible to all children.

As an undergraduate studying mechanical engineering at MIT, Herrero-Marques deeply connected with her studies, yet always felt that something was missing until she got involved with D-Lab.

“I needed the ability to think about social impact more,” she says. “What I’ll remember the most from this trip was recognizing the value and beauty of simple technology.”

Herrero-Marques and four other students joined Libby Hsu, associate director of academics at MIT D-Lab, in the immersive experience. Their goal was to collaborate with local partners to design individualized adaptive solutions to help children with multiple disabilities access education.

Last year in Mérida, Yucatán, Perkins opened its first international workshop that builds adaptive devices and tools. The organization aims to launch similar spaces in additional regions.

“Our vision for the future is to become a Mexican leader in the design and construction of low-cost adaptive designs for students with disabilities in the state of Yucatán,” says Ernesto Santana Palma, the workshop’s manager who welcomed the D-Lab group, designed, and iterated alongside them.

Listening before co-designing

Founded in 2002, D-Lab is open to all MIT students and offers opportunities to co-design in collaboration with local partners to help alleviate poverty-related challenges. Hsu explained that rather than arriving in Mexico with a work plan, the group spent their first week visiting local homes and schools and engaging with their “clients,” the children, their caregivers, and educators, and getting to know the culture of Yucatán, a state with one of the largest Indigenous populations in Mexico.

“We first had to learn about cultural expectations, which materials were available locally, and hear about Indigenous and other regional construction methods,” says Hsu.

Students were overwhelmed by the obvious need, and impressed by how educators and caregivers invented makeshift hacks to help the children engage in daily activities like eating, bathing, getting to school, or sitting up to learn.

Although future trips will address other needs, the group ultimately chose two to focus on for the remaining two weeks: They aimed to add foot and leg support on existing wheelchairs, and they wanted to offer caregivers a safer way to bathe children with mobility issues.

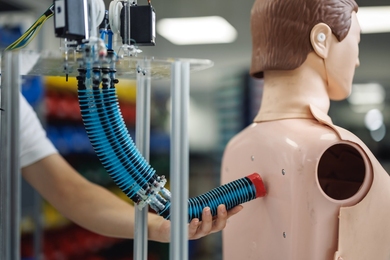

The adaptive bathtub prototype

“D-Lab does a really good job of not only getting you involved in the field, but also giving you a layout and techniques to respectfully approach projects,” says Shruthi Shekar, a senior majoring in biological engineering.

She and her team heard from caregivers how physically taxing and dangerously slippery it felt to bathe children with mobility challenges. They determined that an assistive bathing device could support a child’s body and help immerse them safely in the water. They quickly landed on large plastic bins for tubs — useful for those without access to a bathtub or, in some cases, indoor plumbing. However, finding a porous, affordable fabric to offer full-body support to a child of any size posed a challenge. It was a lightbulb moment when they noticed the sturdy, hand-knotted hammocks hanging in each home.

“The hammocks apply even pressure across the entire body and provide a good amount of support,” says Shekar. “They are comfortable, durable, and made locally.”

In partnership with workshop volunteers who learned the tradition of hammock making from their grandmothers and custom-knotted a prototype to fit a child’s dimensions, Shekar’s team attached a hammock to a plastic tote using strong knots.

The adaptive footrest attachment prototype

A prerequisite for the students’ trip was taking 11.025 (D-Lab: Development), an introductory course taught by Hsu each fall. During one class session, they visited the workshop at Perkins School for the Blind in nearby Watertown, Massachusetts, where they learned how to construct a simple adapted chair from low-cost cardboard. The workshop has produced thousands of seats for children around the world — helping them to sit up safely to eat, learn, and interact.

Herrero-Marques assumed that cardboard would be a useful material in Mexico as well, but quickly discovered that the humid climate makes the ply dissolve. Local teachers explained that because they lack footrest support, children in wheelchairs struggle with leg cramps and slide precariously in their seats, presenting a choking hazard.

“The children don’t have much mobility,” she says. “A standard 90-degree footrest would be painful for them.”

Cardboard was not a solution. The team iterated multiple designs for their adjustable footrest attachment before aligning on a prototype constructed of sealed, lightweight wood.

“Basically, there are two angles that you're able to adjust — the angle at the knee and then at the ankle,” Herrero Marques explains. Each attachment is made to measure for its user.

Children and their families in Yucatán are currently testing out the prototypes. This semester, D-Lab students have continued to iterate the attachment design based on their feedback, and will return to Mexico in June to test out more advanced models.

“I’m never going to look at cardboard, hammocks, or plastic tubs the same way,” Herrero-Marques says. “These are marvels of engineering. Not everything has to be high-tech to make a big impact.”