The ceiling fan is one of the most widely used mechanical appliances in the world. It is also, in many cases, one of the least efficient.

In India, ceiling fans have been used for centuries to get relief from the hot, humid climate. Hand-operated fans called punkahs can be traced as far back as 500 BC and were fixtures of life under the British Raj in the 18th and 19th centuries. Today’s ceiling fans run on electricity and are more ubiquitous than ever. The Indian Fan Manufacturers’ Association reported producing 40 million units in 2014 alone, and the number of fans in use nationwide is estimated in the hundreds of millions, perhaps as many as half a billion.

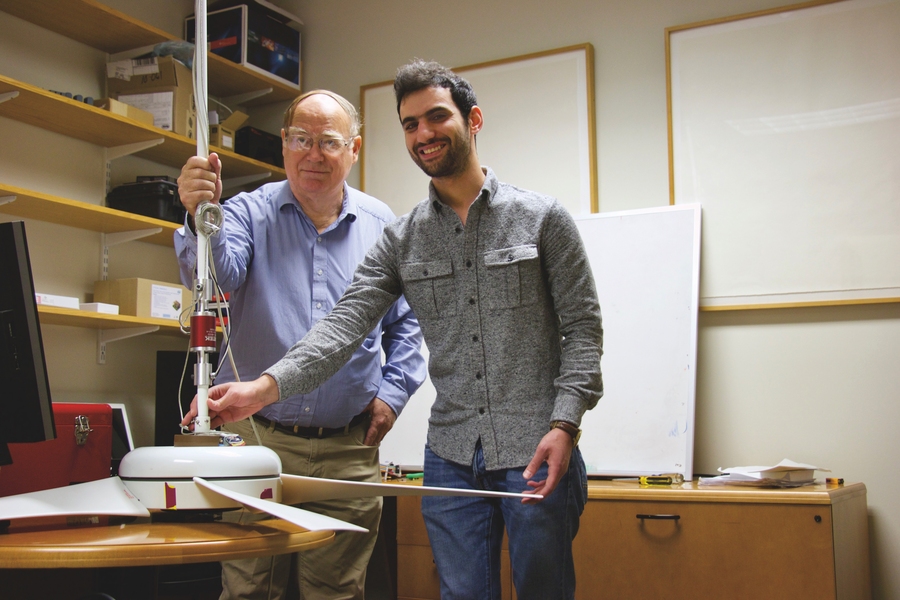

James Kirtley Jr., a professor of electrical engineering at MIT, has been investigating the efficiency of small motors like those found in ceiling fans for more than 30 years.

“A typical ceiling fan in India draws about 80 watts of electricity, and it does less than 10 watts of work on the air,” he says. “That gives you an efficiency of just 12.5 percent.”

Low-efficiency fans pose a variety of energy problems. Consumers don’t get good value for the electricity they buy from the grid, and energy utilities have to deal with the power losses and grid instability that result from low-quality appliances.

But there’s a reason these low-efficiency fans, driven by single-phase induction motors, are so popular: They’re inexpensive. “The best fans on the market in India — those that move a reasonable amount of air and have a low input power — are actually quite costly,” Kirtley says. The high price puts them out of reach for most of India’s population.

Now Kirtley, with support from the Tata Center for Technology and Design, is working on a single-phase motor design that offers high efficiency at an affordable cost. He says the potential impact is huge.

“If every fan in India saved just 2 watts of electricity, that would be the equivalent of a nuclear power plant’s generation capacity,” he says. “If we could make these fans substantially more efficient than they are, operating off of DC electricity, you could imagine extending the use of ceiling fans into rural areas where they could provide a benefit to the quality of life.”

Mohammad Qasim, a graduate student in Kirtley’s research group and a fellow in the Tata Center, says the benefits could reach multiple stakeholders. “Having more efficient appliances means a lower electricity bill for the consumer and fewer power losses on the utility’s side,” he says.

Choosing the right motor

“The idea is to try and hit that high-efficiency mark at a cost that is only a little more than that of existing low-efficiency fans,” Kirtley says. “We imagine a fan that might have an input power of 15 watts and an efficiency of 75 percent.”

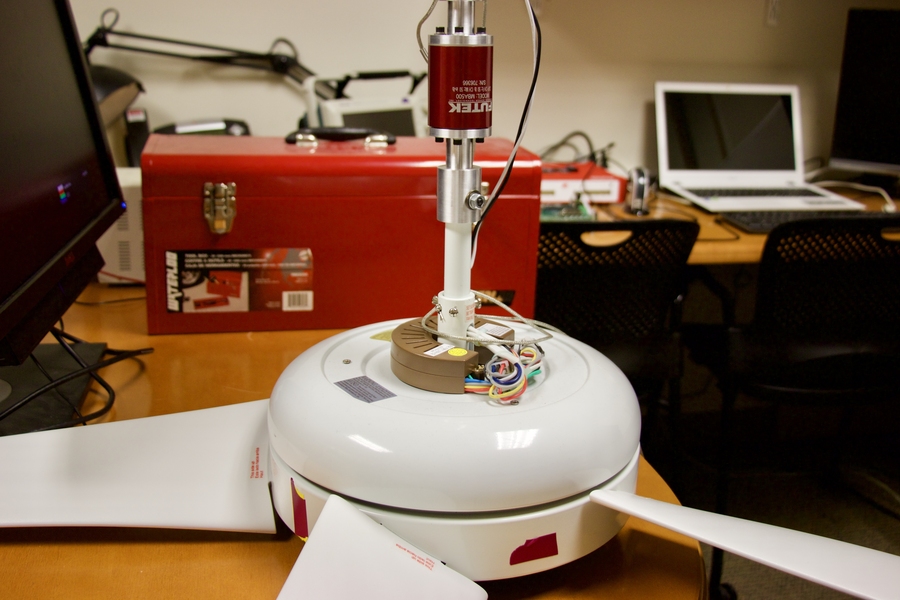

To accomplish that, Kirtley and Qasim are exploring two approaches: creating an improved version of the conventional induction motor, or switching to a brushless DC motor, which may be more expensive but can deliver superior efficiency.

In either case, they plan to use power electronics — devices that control and optimize the flow of electricity through the motor — to improve the power quality and grid compatibility of the fan. Power electronics can also be used to convert AC electricity from the grid into DC, opening up the possibility of using DC motors in ceiling fans.

Brushless DC motors, which are the younger technology, use permanent magnets to establish a magnetic field that creates torque between the motor’s two main components, the rotor and stator. “You can think of it almost like a dog chasing his tail,” Kirtley says. “If I establish the magnetic field in some direction, the magnet turns to align itself in that direction. As I rotate the magnetic field, the magnet moves to align, and that keeps the rotor spinning.”

Induction motors, on the other hand, use no magnets but instead create a rotating magnetic field by flowing current through the stator coils. Because they use AC electricity, they are directly grid compatible, but their efficiency and stability can be improved by using power electronics to optimize the speed of the motor.

International collaboration

In determining which path to take, induction or brushless DC motor, Kirtley and Qasim are leaning on the expertise of Vivek Agarwal, a professor of electrical engineering at the Indian Institute of Technology, Bombay (IITB). Agarwal is a specialist in power electronics.

“The collaboration with Professor Agarwal’s group is so important,” Kirtley says. “They can give us a good idea of what the two different power electronics packages will cost. You would typically think of the brushless motor package as the more expensive option, but it may or may not be.”

Outside of the lab, on-the-ground detective work is key. When Qasim visited India in January 2017, he hit the streets of Mumbai with one of the graduate students from Agarwal’s lab. Together, they visited people across the ceiling fan industry, from manufacturers to repairmen in street-side shops.

“This visit was a big motivation for us,” says Qasim, noting that they were able to glean insights that will help them design a more robust and durable motor. “We want to understand the major maintenance issues that cause these motors to break down so that we can avoid common sources of failure. It was important to make the effort to talk to local people who had real experience repairing these motors.”

Usha International, an appliance manufacturer based in New Delhi, has been a key advisor in the early stages of the project and helped identify ceiling fans as a critical focus area. Engineers at Usha agree with Kirtley’s assessment that there is an unmet need for high-efficiency motors at relatively low cost, and Qasim says the Usha team shared what they had learned from designing their own high-efficiency fans.

Now, Kirtley and Qasim are engaged in the daunting task of envisioning how an ideal motor might look.

“This is a very challenging problem, to design a motor that is both efficient and inexpensive,” Kirtley says. “There’s still a question of which type of motor is going to be the best one to pursue. If we can get a good understanding of what exactly the machine ought to do, we can proceed to do a good machine design.”

Qasim has built a test facility in Kirtley’s laboratory at MIT, which he is using to characterize a variety of existing fans. His experimental data, combined with his fieldwork in India, should provide a set of design requirements for the improved motor. From there, he and Kirtley will work with the IITB researchers to pair the machine with an appropriate power electronics package.

In reducing the power demands of the standard ceiling fan by as much as 65 watts, they hope to have a far-reaching, positive effect on India’s energy system. But that’s only the start. Ultimately, they believe efficient, affordable motors can be applied to a number of common appliances, potentially saving gigawatts of electricity in a country that is working hard to expand reliable energy access for what will soon be the world’s largest population.

This article appeared in the Autumn 2017 issue of Energy Futures, the magazine of the MIT Energy Initiative.