Being a research student requires hours behind a desk. For Concrete Sustainability Hub researcher Thomas Petersen though, it also requires hours of running, and perhaps, even a marathon or two.

“I love running,” Petersen says. “I find that it helps my productivity.”

Petersen has made running a regular part of his research routine. He says that stepping away from his desk and jogging along the adjacent Charles River, he finds he can think about problems “in a different way.”

“Whenever you’re working on a computer or with a paper in front of you, you tend to look at the details,” he explains. “Whereas, if you step back and do something that detaches you from the specifics of the equations you can think about the general processes more.”

Running is a lifestyle for Petersen. He ran as a collegiate athlete at Arizona State University and at North Carolina State University. Since then, he has also completed several marathons, including the New York Marathon, the San Francisco Marathon, and the Boston Marathon — which he has run three times.

And when Petersen isn’t running on pavement, he’s studying it. His work revolves around the material science of concrete and asphalt and, in particular, how they degrade due to their chemical composition or various stresses like temperature change.

In a climate like that of Boston, temperature changes can generate considerable stresses inside pavements. “Something I’ve been studying for much of my PhD is the mechanics of how internal loads develop due to various physical properties,” he says.

“Here in Boston, temperature cycles will have a significant impact. Pavements are laid down on a substrate, and if they expand or contract on the substrate and, the substrate resists that expansion or contraction, cracks can occur. I often see them when I run, actually,” he says. As a result, he says, an ideal subgrade should be stiff and well bonded to the pavement so that loads are effectively transferred.

Yet, sometimes cracks can be beneficial. “Often we try to release energy in the pavement by cutting joints,” says Petersen, “and in that case, it’s not effective to have a rigid connection because you are trying to create cracks that relieve the stresses.” This is why the average sidewalk has lines cut through it, Petersen explains. The lines direct the cracks away from the surface of the sidewalk and discourage it from storing mechanical stress.

Pavement durability also depends on not just how the concrete is set, but also on the textures and composition of the materials. Some of Petersen’s work looks at the formation of calcium-silicate-hydrates (C-S-H), which occur when water and cement clinker, the chemical source and a catalyst for nucleation, are mixed to create cement. Ultimately, this cement is mixed with filler materials like sand and gravel to form concrete.

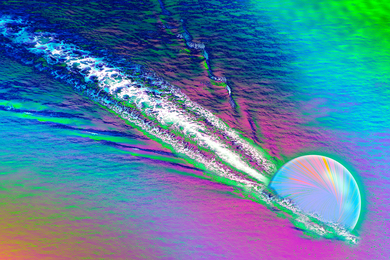

When studying the formation of C-S-H, which occur as nanometer-sized particles, Petersen looks at two key variables — the ability of the particles to diffuse through space and their stability with respect to one another. He has found that when C-S-H form an unstable, rapidly-moving phase the final product looks almost like the pattern of cowhide, with large bubbles of clinker mixing with large pockets of air. This kind of heterogeneous pattern tends to generate more stresses, and, in turn, decreases durability.

However, when C-S-H forms slowly, its pattern becomes more diffuse and homogenous, with small, evenly spaced air pockets and solids. This latter formation is by far the sturdier. Though altering these final patterns is difficult, thanks to his modeling, Petersen has helped to understand how particle mobility and stability determine these final patterns. These findings could provide others with a framework to better engineer nanotextures and, in turn, create a tougher, more resilient material.

As Petersen nears the completion of his PhD, his work on pavements has absorbed much of his attention. While he continues to run, he has chosen to cut back on marathons for the time being.

“I’m not so happy about it,” he laughs, “I’m only running three or four times a week.”

He’s already eying his next marathon, however. Once he finishes his dissertation, he plans to fly to Germany to compete in the Berlin Marathon where he hopes to break 2 hours and 30 minutes. Unlike the past marathons he has run, the Berlin Marathon is relatively flat. “I think if I run Berlin,” he says hopefully, “that that pace might just be possible.”

The MIT Concrete Sustainability Hub (CSHub) is a team of researchers from several departments across MIT working on concrete and infrastructure science, engineering, and economics. Its research is supported by the Portland Cement Association and the Ready Mixed Concrete Research and Education Foundation.