The MIT Energy Initiative (MITEI) will share faculty expertise in clean energy innovation as an academic and research collaborator of the new Rapid Advancement in Process Intensification Deployment (RAPID) Manufacturing Institute, which the U.S. Department of Energy (DOE) has announced as the newest — and 10th — institute in the nation’s network of Manufacturing USA Institutes. In a coalition led by the American Institute of Chemical Engineers (AIChE), MITEI and other academic, national lab, and industry organizations will work together in the RAPID Manufacturing Institute to intensify industrially important processes, making them more energy-efficient and reducing their environmental impact.

Traditional chemical manufacturing relies on large-scale, energy-intensive processing. The new institute will leverage approaches to modular chemical process intensification — like combining multiple, complex processes such as mixing, reaction, and separation into single steps — with the goal of improving energy productivity and efficiency, cutting operating costs, and reducing waste. In the chemical industry alone, these technologies have the potential to save more than $9 billion in process costs annually.

To date, RAPID has enlisted 75 companies, 34 academic institutions, seven national laboratories, two other government laboratories, and seven non-governmental organizations from all regions of the country. These members have committed to cost shares that leverage DOE’s $70 million contribution over five years, with total project spending exceeding $140 million. RAPID’s members come from energy-intensive industries and range from small to large enterprises.

DOE Acting Assistant Secretary of the Office of Energy Efficiency and Renewable Energy David Friedman says, “Our investment in this cross-cutting technology is an investment in the future of manufacturing in the U.S. As we expand the Manufacturing USA network, we provide greater opportunities for businesses of all sizes to solve their toughest technology challenges and unleash major savings in energy-intensive sectors like oil and gas, pulp and paper-making and other industries.”

A creative team of MIT researchers is offering their unique expertise in RAPID’s focus area of process intensification. Process intensification is an approach to industrial processing that attempts to combine multiple functions and steps into an integrated and streamlined process for energy savings and increases in efficiency.

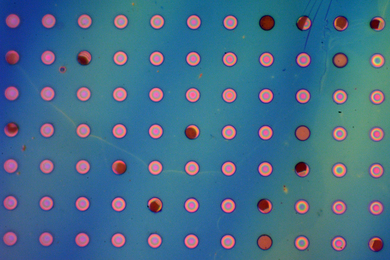

Michael Strano, the Carbon P. Dubbs Professor of Chemical Engineering at MIT, is the principal investigator on the project. He says, “Imagine that we could make a chemical reactor that was itself a membrane, separating and purifying the reactant in the reactor, with integrated heat transfer and product purification all in one process. The process is intensified — smaller perhaps in physical footprint, environmental footprint, and energy consumption. But it requires a rethinking of the whole process, an integrated approach.”

Paula Hammond, head of the MIT Department of Chemical Engineering, says, “This institute provides an opportunity for MIT and all of the collaborators in RAPID to completely disrupt the way we think about making things.” She adds, “It is significant that our national chemical engineering professional society, AIChE, heads this effort as it represents the ability to tie together strong academic, industrial, and governmental teams to address the very broad spectrum of problems that chemical engineers cover, from traditional chemical production to the generation of cell-derived biologic drugs. These new efforts mark an exciting time for chemical engineering, and we have such strong participation from our own faculty, who are leading at the frontiers of this new approach to process development and design.”

The RAPID research initiatives proposed by the MIT team include projects to streamline bioreactor processes, particulate production, gas purification using membranes as well as other important technologies.

MITEI — MIT’s energy hub for multidisciplinary research, education, and outreach — will house activities for the Institute’s involvement in the coalition. MIT researchers will collaborate with software and manufacturing companies based in Massachusetts, many of which were launched and have grown using technology developed at MIT.

“Process intensification technologies have the potential to dramatically reduce costs in manufacturing and achieve great energy efficiency gains — valuable contributions to achieving a low-carbon energy future,” says Robert C. Armstrong, director of MITEI. “At MITEI, we convene researchers from across the Institute to focus their expertise on solving energy-specific challenges and engaging with policy makers and industry professionals, as the RAPID research team is doing here.”

Greg Stephanopoulos, the W.H. Dow Professor of Chemical Engineering at MIT and president of AIChE, says, “The RAPID collaboration will catalyze intense and targeted collaborations of industry, academia and national laboratories aiming at the development of new products and advanced processes with the overall goal of improving the competitiveness of the American chemical industry. MIT faculty members in Chemical Engineering and other departments are looking forward to active participation.”

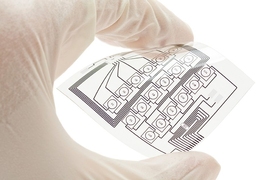

“MIT engagement in RAPID builds on our growing talent and investment in manufacturing innovation, from new education and workforce training approaches to strengthened industry and regional collaborations that transition our R&D from prototype to pilot-scale production in these Manufacturing USA Institutes,” notes Krystyn J. Van Vliet, professor and director of manufacturing innovation for the MIT Innovation Initiative. MIT also participates in six other Manufacturing USA Institutes, including the National Institute for Innovation in Manufacturing Biopharmaceuticals; Clean Energy Smart Manufacturing Innovation Institute; the Advanced Functional Fabrics of America Institute; NextFlex, America’s flexible hybrid electronics manufacturing innovation institute; the American Institute for Manufacturing Integrated Photonics (AIM Photonics); and Lightweight Innovators for Tomorrow (LIFT).

In addition to Strano, Stephanopoulos, Van Vliet, and Hammond, MIT faculty engaged in the development of the RAPID Manufacturing Institute proposal development and example technical projects include Department of Chemical Engineering faculty members Richard Braatz, Fikile Brushett, Bill Green, T. Alan Hatton, Klavs Jensen, Karthish Manthiram, Allan Myerson, Kristala Prather, Yuriy Roman, and Zachary Smith, and Department of Chemistry faculty member Yogesh Surendranath.

Additional information about the RAPID Manufacturing Institute and its objectives can be found at processintensification.org.