Researchers at MIT and Brigham and Women’s Hospital have developed a new way to produce nanoparticles that can deliver drugs for cancer and other diseases. The new production system offers greater control over the size and composition of the particles, allowing large quantities of homogenous particles to be rapidly produced.

The particles are formed from a commonly used biodegradable polymer that can carry a large number of drug molecules and release them in a controlled fashion while evading the body’s immune system.

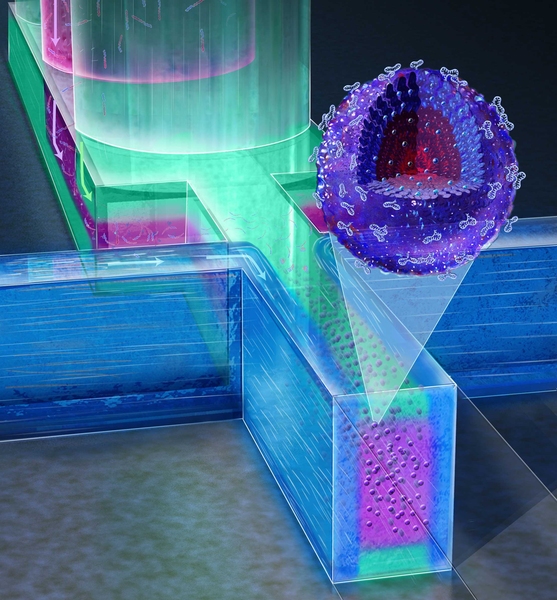

In the new production system, a stream of the polymer flows through a microfluidic channel that focuses it three-dimensionally, isolating it from the channel walls and allowing spherical nanoparticles to form when the polymer contacts water side streams. In traditional two-dimensional systems, polymers often clump along the top and bottom walls, clogging the device. The new system uses streams of an organic solvent called acetonitrile to keep the polymers away from the top and bottom walls and prevent such clumping.

The researchers reported their new system in the Feb. 22 online edition of the journal Advanced Materials. Authors are Minsoung Rhee, postdoctoral associate at MIT and Brigham and Women’s; MIT graduate student Pedro Valencia; MIT senior Maria Rodriguez; Institute Professor Robert Langer; Omid Farokhzad, director of the Laboratory of Nanomedicine and Biomaterials at Brigham and Women’s Hospital; and MIT assistant professor of mechanical engineering Rohit Karnik.

New 3-D microfluidic system offers greater control over production of drug-delivering nanoparticles.

Publication Date:

Caption:

In this artist’s rendering of the new system, polymers flow through a microfluidic channel as they are formed into spherical nanoparticles. An organic solvent called acetonitrile helps keep the particles away from the walls and prevent clumping.

Credits:

Image: Nicolle Rager Fuller/Sayo-Art

Caption:

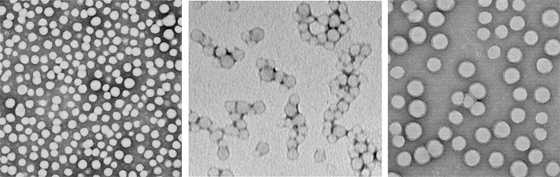

A comparison of the new 3-D system, top, and an older 2-D system, bottom, shows that nanoparticles in the 2-D system tend to clump together, eventually causing the device to fail.

Credits:

Image: Dr. Minsoung Rhee

Caption:

Using the new system, the researchers created particles highly homogenous in size — seen from left to right — with diameters of 33 nanometers, 55 nanometers and 200 nanometers.

Credits:

Image: Pedro M. Valencia