Audio

The advanced semiconductor material gallium nitride will likely be key for the next generation of high-speed communication systems and the power electronics needed for state-of-the-art data centers.

Unfortunately, the high cost of gallium nitride (GaN) and the specialization required to incorporate this semiconductor material into conventional electronics have limited its use in commercial applications.

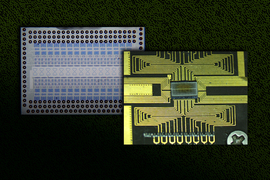

Now, researchers from MIT and elsewhere have developed a new fabrication process that integrates high-performance GaN transistors onto standard silicon CMOS chips in a way that is low-cost and scalable, and compatible with existing semiconductor foundries.

Their method involves building many tiny transistors on the surface of a GaN chip, cutting out each individual transistor, and then bonding just the necessary number of transistors onto a silicon chip using a low-temperature process that preserves the functionality of both materials.

The cost remains minimal since only a tiny amount of GaN material is added to the chip, but the resulting device can receive a significant performance boost from compact, high-speed transistors. In addition, by separating the GaN circuit into discrete transistors that can be spread over the silicon chip, the new technology is able to reduce the temperature of the overall system.

The researchers used this process to fabricate a power amplifier, an essential component in mobile phones, that achieves higher signal strength and efficiencies than devices with silicon transistors. In a smartphone, this could improve call quality, boost wireless bandwidth, enhance connectivity, and extend battery life.

Because their method fits into standard procedures, it could improve electronics that exist today as well as future technologies. Down the road, the new integration scheme could even enable quantum applications, as GaN performs better than silicon at the cryogenic temperatures essential for many types of quantum computing.

“If we can bring the cost down, improve the scalability, and, at the same time, enhance the performance of the electronic device, it is a no-brainer that we should adopt this technology. We’ve combined the best of what exists in silicon with the best possible gallium nitride electronics. These hybrid chips can revolutionize many commercial markets,” says Pradyot Yadav, an MIT graduate student and lead author of a paper on this method.

He is joined on the paper by fellow MIT graduate students Jinchen Wang and Patrick Darmawi-Iskandar; MIT postdoc John Niroula; senior authors Ulrich L. Rohde, a visiting scientist at the Microsystems Technology Laboratories (MTL), and Ruonan Han, an associate professor in the Department of Electrical Engineering and Computer Science (EECS) and member of MTL; and Tomás Palacios, the Clarence J. LeBel Professor of EECS, and director of MTL; as well as collaborators at Georgia Tech and the Air Force Research Laboratory. The research was recently presented at the IEEE Radio Frequency Integrated Circuits Symposium.

Swapping transistors

Gallium nitride is the second most widely used semiconductor in the world, just after silicon, and its unique properties make it ideal for applications such as lighting, radar systems and power electronics.

The material has been around for decades and, to get access to its maximum performance, it is important for chips made of GaN to be connected to digital chips made of silicon, also called CMOS chips. To enable this, some integration methods bond GaN transistors onto a CMOS chip by soldering the connections, but this limits how small the GaN transistors can be. The tinier the transistors, the higher the frequency at which they can work.

Other methods integrate an entire gallium nitride wafer on top of a silicon wafer, but using so much material is extremely costly, especially since the GaN is only needed in a few tiny transistors. The rest of the material in the GaN wafer is wasted.

“We wanted to combine the functionality of GaN with the power of digital chips made of silicon, but without having to compromise on either cost of bandwidth. We achieved that by adding super-tiny discrete gallium nitride transistors right on top of the silicon chip,” Yadav explains.

The new chips are the result of a multistep process.

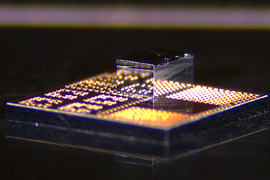

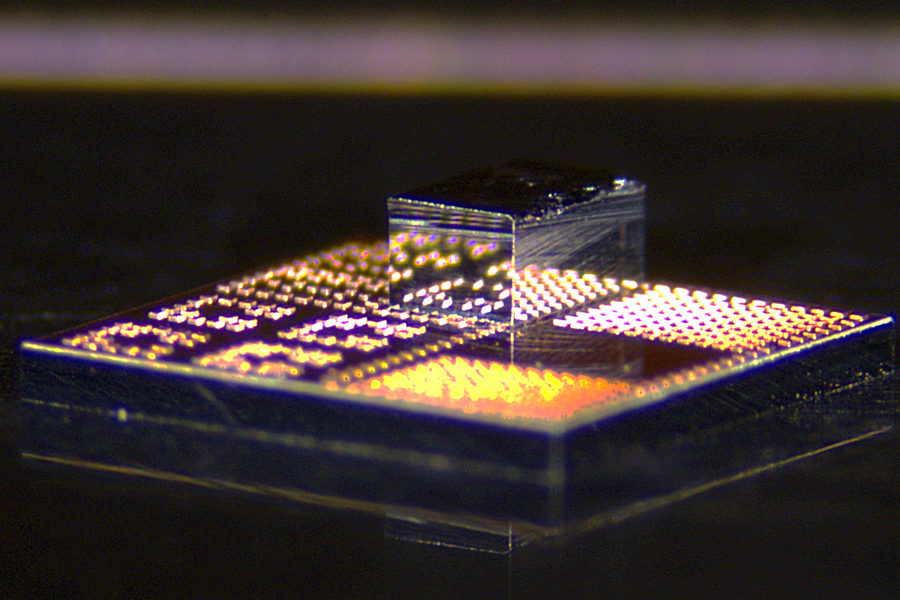

First, a tightly packed collection of miniscule transistors is fabricated across the entire surface of a GaN wafer. Using very fine laser technology, they cut each one down to just the size of the transistor, which is 240 by 410 microns, forming what they call a dielet. (A micron is one millionth of a meter.)

Each transistor is fabricated with tiny copper pillars on top, which they use to bond directly to the copper pillars on the surface of a standard silicon CMOS chip. Copper to copper bonding can be done at temperatures below 400 degrees Celsius, which is low enough to avoid damaging either material.

Current GaN integration techniques require bonds that utilize gold, an expensive material that needs much higher temperatures and stronger bonding forces than copper. Since gold can contaminate the tools used in most semiconductor foundries, it typically requires specialized facilities.

“We wanted a process that was low-cost, low-temperature, and low-force, and copper wins on all of those related to gold. At the same time, it has better conductivity,” Yadav says.

A new tool

To enable the integration process, they created a specialized new tool that can carefully integrate the extremely tiny GaN transistor with the silicon chips. The tool uses a vacuum to hold the dielet as it moves on top of a silicon chip, zeroing in on the copper bonding interface with nanometer precision.

They used advanced microscopy to monitor the interface, and then when the dielet is in the right position, they apply heat and pressure to bond the GaN transistor to the chip.

“For each step in the process, I had to find a new collaborator who knew how to do the technique that I needed, learn from them, and then integrate that into my platform. It was two years of constant learning,” Yadav says.

Once the researchers had perfected the fabrication process, they demonstrated it by developing power amplifiers, which are radio frequency circuits that boost wireless signals.

Their devices achieved higher bandwidth and better gain than devices made with traditional silicon transistors. Each compact chip has an area of less than half a square millimeter.

In addition, because the silicon chip they used in their demonstration is based on Intel 16 22nm FinFET state-of-the-art metallization and passive options, they were able to incorporate components often used in silicon circuits, such as neutralization capacitors. This significantly improved the gain of the amplifier, bringing it one step closer to enabling the next generation of wireless technologies.

“To address the slowdown of Moore’s Law in transistor scaling, heterogeneous integration has emerged as a promising solution for continued system scaling, reduced form factor, improved power efficiency, and cost optimization. Particularly in wireless technology, the tight integration of compound semiconductors with silicon-based wafers is critical to realizing unified systems of front-end integrated circuits, baseband processors, accelerators, and memory for next-generation antennas-to-AI platforms. This work makes a significant advancement by demonstrating 3D integration of multiple GaN chips with silicon CMOS and pushes the boundaries of current technological capabilities,” says Atom Watanabe, a research scientist at IBM who was not involved with this paper.

This work is supported, in part, by the U.S. Department of Defense through the National Defense Science and Engineering Graduate (NDSEG) Fellowship Program and CHIMES, one of the seven centers in JUMP 2.0, a Semiconductor Research Corporation Program by the Department of Defense and the Defense Advanced Research Projects Agency (DARPA). Fabrication was carried out using facilities at MIT.Nano, the Air Force Research Laboratory, and Georgia Tech.