Audio

Around 5,000 years ago, people living in what is now Iran began extracting copper from rock by processing ore, an activity known as smelting. This monumental shift gave them a powerful new technology and may have marked the birth of metallurgy. Soon after, people in different parts of the world were using copper and bronzes (alloys of copper and tin, or copper and arsenic) to produce decorative objects, weapons, tools, and more.

Studying how humans produced such objects is challenging because little evidence still exists, and artifacts that have survived are carefully guarded and preserved.

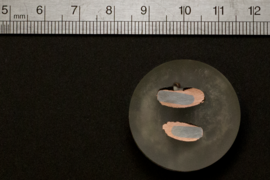

In a paper published in PLOS One, MIT researchers demonstrated a new approach to uncovering details of some of the earliest metallurgical processes. They studied 5,000-year-old slag waste, a byproduct of smelting ore, using techniques including X-ray computed tomography, also known as CT scanning. In their paper, they show how this noninvasive imaging technique, which has primarily been used in the medical field, can reveal fine details about structures within the pieces of ancient slag.

“Even though slag might not give us the complete picture, it tells stories of how past civilizations were able to refine raw materials from ore and then to metal,” says postdoc Benjamin Sabatini. “It speaks to their technological ability at that time, and it gives us a lot of information. The goal is to understand, from start to finish, how they accomplished making these shiny metal products.”

In the paper, Sabatini and senior author Antoine Allanore, a professor of metallurgy and the Heather N. Lechtman Professor of Materials Science and Engineering, combined CT scanning with more traditional methods of studying ancient artifacts, including cutting the samples for further analysis. They demonstrated that CT scanning could be used to complement those techniques, revealing pores and droplets of different materials within samples. This information could shed light on the materials used by and the technological sophistication of some of the first metallurgists on Earth.

“The Early Bronze Age is one of the earliest reported interactions between mankind and metals,” says Allanore, who is also director of MIT’s Center for Materials Research in Archaeology and Ethnology. “Artifacts in that region at that period are extremely important in archaeology, yet the materials themselves are not very well-characterized in terms of our understanding of the underlying materials and chemical processes. The CT scan approach is a transformation of traditional archaeological methods of determining how to make cuts and analyze samples.”

A new tool in archaeology

Slag is produced as a molten hot liquid when ores are heated to produce metal. The slag contains other constituent minerals from the ore, as well as unreacted metals, which are commonly mixed with additives like limestone. In the mixture, the slag is less dense than the metal, so it can rise and be removed, solidifying like lava as it cools.

“Slag waste is chemically complex to interpret because in our modern metallurgical practices it contains everything not desired in the final product — in particular, arsenic, which is a key element in the original minerals for copper,” says Allanore. “There’s always been a question in archaeometallurgy if we can use arsenic and similar elements in these remains to learn something about the metal production process. The challenge here is that these minerals, especially arsenic, are very prone to dissolution and leaching, and therefore their environmental stability creates additional problems in terms of interpreting what this object was when it was being made 6,000 years ago.”

For the study, the researchers used slag from an ancient site known as Tepe Hissar in Iran. The slag has previously been dated to the period between 3100 and 2900 BCE and was loaned by the Penn Museum to Allanore for study in 2022.

“This region is often brought up as one of the earliest places where evidence of copper processing and object production might have happened,” Allanore explains. “It is very well-preserved, and it’s an early example of a site with long-distance trade and highly organized society. That’s why it’s so important in metallurgy.”

The researchers believe this is the first attempt to study ancient slag using CT scanning, partly because medical-grade scanners are expensive and primarily located in hospitals. The researchers overcame these challenges by working with a local startup in Cambridge that makes industrial CT scanners. They also used the CT scanner on MIT’s campus.

“It was really out of curiosity to see if there was a better way to study these objects,” Sabatini said.

In addition to the CT scans, the researchers used more conventional archaeological analytical methods such as X-ray fluorescence, X-ray diffraction, and optical and scanning electron microscopy. The CT scans provided a detailed overall picture of the internal structure of the slag and the location of interesting features like pores and bits of different materials, augmenting the conventional techniques to impart more complete information about the inside of samples.

They used that information to decide where to section their sample, noting that researchers often guess where to section samples, unsure even which side of the sample was originally facing up or down.

“My strategy was to zero in on the high-density metal droplets that looked like they were still intact, since those might be most representative of the original process,” Sabatini says. “Then I could destructively analyze the samples with a single slice. The CT scanning shows you exactly what is most interesting, as well as the general layout of things you need to study.”

Finding stories in slag

In previous studies, some slag samples from the Tepe Hissar site contained copper and thus seemed to fit the narrative that they resulted from the production of copper, while others showed no evidence of copper at all.

The researchers found that CT scanning allowed them to characterize the intact droplets that contained copper. It also allowed them to identify where gases evolved, forming voids that hold information about how the slags were produced.

Other slags at the site had previously been found to contain small metallic arsenide compounds, leading to disagreements about the role of arsenic in early metal production. The MIT researchers found that arsenic existed in different phases across their samples and could move within the slag or even escape the slag entirely, making it complicated to infer metallurgical processes from the study of arsenic alone.

Moving forward, the researchers say CT scanning could be a powerful tool in archaeology to unravel complex ancient materials and processes.

“This should be an important lever for more systematic studies of the copper aspect of smelting, and also for continuing to understand the role of arsenic,” Allanore says. “It allows us to be cognizant of the role of corrosion and the long-term stability of the artifacts to continue to learn more. It will be a key support for people who want to investigate these questions.”

This work was supported, in part, by the MIT Human Insight Collaborative (MITHIC). The X-ray CT system is supported by MIT's Center for Advanced Production Technologies.