Form-fitting clothing is not always governed by sartorial choice. The global pandemic, for example, has underscored the need for face masks that effectively seal around the nose and mouth. But faces and their features differ from one person to the next and can render one-size-fits-all face masks less effective. Well-fitting masks have proved to be a sought-after accessory.

Lavender Tessmer, a doctoral candidate in MIT’s Department of Architecture, has developed a new active fiber and designed a process that — combined with a specific knit textile architecture — uses heat to activate a mask to conform to an individual’s face. With standard textile equipment and the new customization process, any manufacturer can create a customized mask.

Before coming to MIT in 2017, Tessmer had no formal introduction to textiles. She began working with Skylar Tibbits, associate professor in the Department of Architecture and founder of the Self-Assembly Lab, where programmable materials — simple materials that can be activated to sense, respond, and transform — are among its research topics. The following year, the lab purchased an industrial flatbed knitting machine, ubiquitous in textile manufacturing around the world, and Tessmer set to work learning how to operate it.

“It has a huge learning curve, and there are an infinite number of things you can do with a machine like this,” says Tessmer.

Her early start with the knitting machine was prescient for the work to come.

A head start

A few years before the pandemic, Tibbits’s lab received a grant from Advanced Functional Fibers of America (AFFOA) to develop “smarter textiles” that would be able to sense, respond, and transform. The research led to a partnership with Ministry of Supply — a fashion company specializing in high-tech apparel — to develop a new system for “smart textiles.” Created by MIT graduates, Ministry of Supply uses temperature-regulating material to design and produce environmentally sustainable clothing geared to professionals.

In spring 2020, a confluence of events shifted their collaboration. The global pandemic forced businesses to close in March; the Department of Architecture called for proposals to fund research positions for students to work with faculty on “crisis-related research,” including design responses to the pandemic; and the need for masks to protect first responders and the general public became apparent. Tibbits’s research received department funding.

“Lavender was already trying to make textile apparel with a customized fit, so we could quickly transition to making customized masks,” says Tibbits. “But the main challenge with any customization is that you cannot make each mask unique. It becomes a factory logistics problem. You have to be able to mass-produce these. Customers don’t want to wait weeks or months for their unique mask.”

How, then, is a mass-produced mask tailored for an individual face?

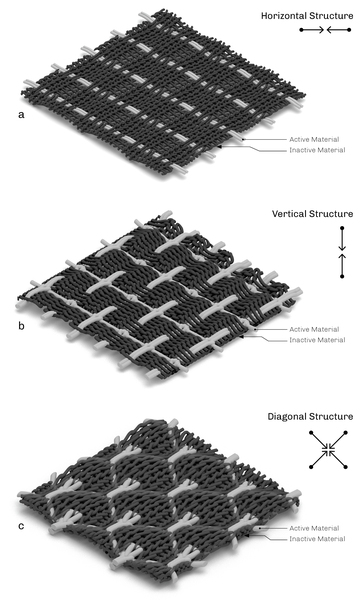

“Lavender created the knit structure — the architecture — of the mask,” says Tibbits. “The material properties alone don’t lead to the behavior of precise transformation. It’s basically two- or three-dimensionally knitting structures, and with every single stitch you can change the structure and the materials.”

Tessmer also developed one of the two active fibers (the other was already commercially available) needed to respond to heat so the fabric could be controlled in a predictable way.

“There had to be a clear relationship between how much heat is applied, the method of applying it with the robot, and having a predictable result in the dimensional transformation of the fabric,” says Tessmer. “That was an iterative process between developing the multi-layered fabric, measuring its dimensional change, and then eventually being able to have the robot apply heat in a repeatable and predicable way.”

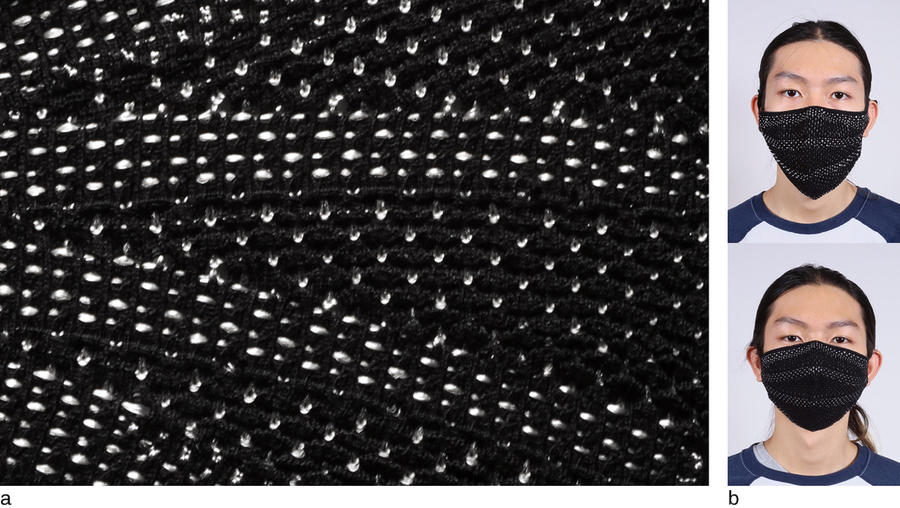

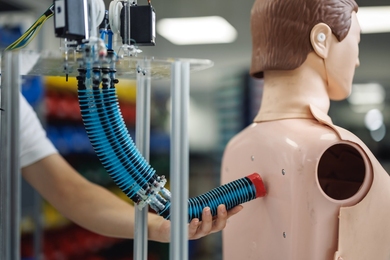

Already in the public realm were guidelines for existing ranges of human facial feature measurements. The starting shape of the mask is large enough for almost every face before it’s transformed and customized. From there, Tessmer input dimensions from an individual’s face and the knit masks were activated with a robotic arm outfitted with a heat gun that applies heat in specific patterns to tailor them precisely to the facial measurements.

Covid-driven need for masks

With their retail operations closed early in the pandemic, Ministry of Supply pivoted from making clothes to making face masks.

“The strength of Lavender and Skylar’s work is that it takes advantage of additive manufacturing techniques, which can be spun up for production very quickly,” says Gihan Amarasiriwardena ’11, a Ministry of Supply co-founder and the company’s president. “Working with the Self-Assembly Lab, we were able to design, test, and develop a mask in five days and have 4,000 masks produced in two weeks for health care workers due to our ability to use 3D computerized knitting. I think this will be a critical asset in being able to divert existing materials toward masks very quickly in the future.”

“The objective was to transform a mask to achieve the perfect fit for anyone’s face, which is a major challenge with masks and other pieces of clothing,” says Tibbits. “No one has really figured out how to do that, other than hiring a tailor or having lots of standard sizes that don’t fit perfectly.”

It is important to note that Tessmer and Tibbits’s work was focused on a mask’s fit, and not the properties required for a mask’s material to filter out airborne particles — although a standard filter could be included to enhance its efficacy. The masks are also reusable and washable.

“Our goal was better fibers and a controllable, repeatable process to create a custom-fit mask,” says Tessmer. “We created masks for nine different people to demonstrate how effective the process is.”

Last fall a paper they co-authored, “Personalized Knit Masks: Programmable Shape Change for Customized Fit,” provided instructions to create “truly customizable masks” that conform to the unique facial features of any individual. The Association for Computer Aided Design in Architecture (ACADIA) honored Tessmer and Tibbits with its Best Paper Award for this groundbreaking work.

“The award highlights the paper as exemplary, showcasing innovative research with substantial contribution to the described field,” noted the judges in their remarks. “Beyond demonstrating rigorous methods of research and disciplinary expertise, the paper is also well-written, bringing new insights to the ACADIA community and beyond.

The evolution of SARS-CoV-2 variants suggests the need for high-quality masks will persist, and the U.S. Centers for Disease Control continue to support their use. Amarasiriwardena believes there will continue to be consumer interest and need for masks, if only seasonally when people are indoors more frequently. He says the fit and comfort of a mask is the second question customers ask, after the efficacy of the filter media.

“Overall efficacy is tied to fit, which is unlocked by personalized manufacturing,” says Amarasiriwardena. “The Self-Assembly Lab has really been pushing the bounds of additive manufacturing, and their recent work in textiles marries their expertise in ‘hacking’ CAD-CAM flows to create truly novel soft goods. While much of the attention has focused on 3D-printing hard goods, their innovation in textiles shows a broad application of the self-assembly technology.”

Tessmer says the masks were a great case study because they were a sought-after accessory the last few years, and there have been noticeable problems with how masks fit. She would like to apply the process to other types of garments and accessories, such as sweaters and shoes.

“At the end of every project there are always things you find that need to be improved upon,” Tessmer says. “There’s a lot of future fabric development, for example. But I’m happy with the project because it is a working proof-of-concept for my idea, and I’m confident that it works.”