With the Covid-19 virus disrupting the global economy, what is the effect on the international supply chain? In a pair of articles, MIT News examines core supply-chain issues, in terms of affected industries and the timing of unfolding interruptions.

The rapid spread of the Covid-19 virus is already having a huge impact on the global economy, which is rippling around the world via the long supply chains of major industries.

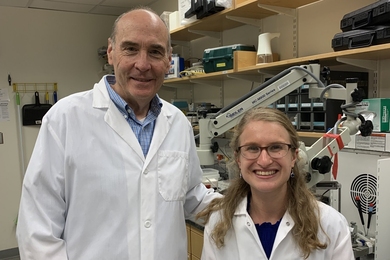

MIT supply chain expert David Simchi-Levi has been watching those ripples closely in 2020, as they have moved from China outward to the U.S. and Europe. His tracking of supply chain problems provides insight into what is happening in the global economy — and what could happen in a variety of scenarios.

“This is a significant challenge,” says Simchi-Levi, who is a professor of engineering systems in the School of Engineering and in the Institute for Data, Systems, and Society within the MIT Stephen A. Schwarzman College of Computing. The global public health crisis, he adds, “is not only affecting the supply chain. There is a significant impact on demand, and as a result, a significant impact on the financial performance on all these businesses.”

In late February, Simchi-Levi and technology executive Pierre Haren issued a short-term forecast, in a Harvard Business Review blog, that the effects of Covid-19 in China would lead to a manufacturing slowdown in the U.S. and Europe by mid-March. Why? Because many Chinese manufacturing suppliers temporarily, but drastically, cut production in late January, due to the problems caused by the virus. Given the timetable of global shipping, that meant major manufacturers would be low on supplies about six weeks later.

“The last shipment to deliver products arrived at the end of February, because it takes about 30 days from Asia to North America or Europe,” says Simchi-Levi. “Most manufacturing companies will keep about two weeks of inventory. That means they were able to cover demand for the first two weeks of March. After that, [given] no more supplies, there will be disruption of manufacturing. And we see this right now.”

Indeed, most major automakers have cut production in the days since mid-March, with Volkswagen and Renault shuttering facilities in Europe as a result. In the U.S., most major automakers announced last week they were temporarily closing plants due to health and safety concerns, with Honda explicitly stating on March 18 that they would enact a temporary shutdown “due to an anticipated decline in market demand related to the economic impact of the Covid-19 pandemic,” as well as in response to health concerns.

“Our prediction that was made in the last week of February has been realized now,” Simchi-Levi says. “Automotive manufacturing companies are closing facilities. Not only are they reducing production — they are closing facilities.”

However, China’s public health situation has been improving in recent weeks, with a reduction in the rate of new Covid-19 cases and fatalities. If the public health situation in the U.S. and Europe did not worsen, then a return to something like normal manufacturing output would be conceivable by the end of the second quarter, Simchi-Levi says.

Looking at survey data from over 3,000 suppliers in China, Simchi-Levi notes that about half of employees at Chinese suppliers were not anticipating being at full capacity until the end of March. The remaining suppliers anticipate a much longer recovery to full capacity.

“These suppliers are starting to come back,” Simchi-Levi says, noting that in the best-case scenario, “We will not see significant volume [from China] before the end of April.”

However, with the U.S. and many European countries continuing to see a rapid increase in Covid-19 cases and deaths throughout March, and curtailing social and economic activity, the best-case scenario seems unlikely.

“At the beginning the problem was reduction in supply,” says Simchi-Levi, referring to China’s production issues. “But now it is not only a matter of supply from China; it is supply from everywhere. Second, the demand side is completely changing. Now there is a big drop in demand.” With unemployment rising and consumer spending reduced, fewer large manufacturers can keep operating at full capacity or anything close to it.

“This also implies a third element, which is the financial impact on companies,” Simchi-Levi says. “It’s not just disruption in the supply chain; the significant drop in demand has a significant financial impact.” So, even if China and other Asian countries rebound relatively quickly, businesses in the U.S. and Europe might not have the capacity to ramp up production and rehire workers at their previous levels.

“You can see there are cascading effects that have an impact,” Simchi-Levi says. Clearly, without an abatement of the spread of Covid-19, a substantial economic uptick is hard to imagine.

“This is all fluid and dynamic,” he warns.

For more on the connection between China and global manufacturing, see our other story about the Covid-19 crisis and supply chain.

![“Most manufacturing companies will keep about two weeks of inventory,” says David Simchi-Levi, who is a professor of engineering systems in the School of Engineering and in the Institute for Data, Systems, and Society within the MIT Stephen A. Schwarzman College of Computing. "That means they were able to cover demand for the first two weeks of March. After that, [given] no more supplies, ther...](/sites/default/files/styles/news_article__image_gallery/public/images/202003/MIT-SupplyChain-Simchi-Levi-01_0.jpg?itok=hwIrfdw8)