The MIT Concrete Sustainability Hub (CSHub), a research center devoted to concrete and infrastructure science, engineering, and economics, has received $10 million in funding from its industry partners to support research by interdisciplinary investigators from several MIT departments.

The funding enables the CSHub to continue work that began with its launch in 2009 and brings to $20 million the total investment by its industry partners, the Portland Cement Association (PCA) and Ready Mixed Concrete (RMC) Research & Education Foundation.

“The Concrete Sustainability Hub is an exceptional collaboration that allows our students, staff, and faculty to have a direct impact on a major industry and to contribute to addressing important societal challenges,” says Ian A. Waitz, dean of the MIT School of Engineering. “Collaborations that allow us to work hand-in-hand with industry sponsors to tackle such problems, as is the case with the CSHub, have a special attraction for us.”

Concrete’s durability, strength, and relatively low cost make it the backbone of buildings and infrastructure worldwide — houses, schools, and hospitals, as well as airports, bridges, highways, and rail systems. The most-produced material on Earth will only be in greater demand as, for example, developing nations become increasingly urban, extreme weather events necessitate more durable building materials, and the price of other infrastructure materials continues to rise.

The CSHub addresses the sustainability and environmental implications of the production and use of concrete. Its research aims to fine-tune the composition of concrete, reduce the greenhouse gas emissions of its production, and quantify its environmental impact and cost during the entire lifespan of an infrastructure or building project.

In its second five-year phase, the CSHub — which is based in MIT’s Department of Civil and Environmental Engineering — will build on initial advances and translate results into engineering practice.

“Working with PCA and the RMC Research & Education Foundation allows us to find ways to bridge the valley between our lab-scale inventions and full-scale innovation in engineering practice,” says Franz-Josef Ulm, faculty director of the CSHub and the George Macomber Professor of Civil and Environmental Engineering at MIT. “We must fully communicate the potential for quantitative sustainable engineering to transform current engineering practice.”

CSHub researchers are investigating concrete from the nanoscale up, and they are analyzing its full life cycle — something that planners and policymakers rarely do. Concrete has benefits that offset the carbon footprint of its production, such as minimizing maintenance, repair, and heating and cooling needs throughout the life of a structure.

“As the call for an increased emphasis on environmental issues in the building industry grows louder, concrete manufacturers are making a long-term investment in research that can move us toward greater sustainability,” says Julia Garbini, executive director of the RMC Research & Education Foundation.

PCA President and CEO Gregory Scott says, “Breakthroughs in concrete science and engineering hold the promise that concrete can be part of the solution of contributing to sustainable development and reducing the carbon footprint of our built environment.”

Results of CSHub research so far include:

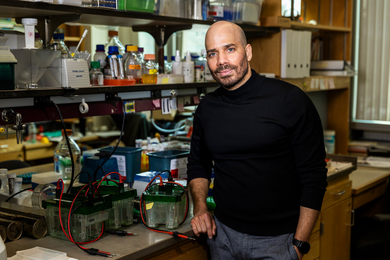

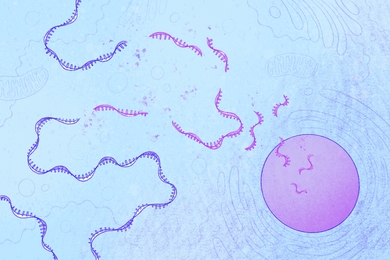

- Understanding the basic structure of concrete: Researchers created an atomic-scale model of a basic unit they call the DNA of concrete: calcium-silica-hydrate, or the paste that forms and hardens when cement powder mixes with water. (The abbreviated name of this “liquid stone,” C-S-H, inspired the name of the CSHub.) Based on these findings, CSHub scientists have been able to, for example, determine the optimal composition of C-S-H that would enable concrete structures to resist “creep” — cracks and other deformations that develop in concrete over time.

- Investigating better pavements: CSHub scientists found that using stiffer pavements — whether concrete, asphalt, or a composite of the two — could reduce vehicle fuel consumption by as much as 3 percent nationwide, potentially reducing annual carbon dioxide emissions by 46.5 million metric tons. They are also examining the roughness of different pavement materials and how roughness affects fuel efficiency.

- Assessing concrete’s life cycle and long-term costs: New life-cycle assessment (LCA) tools being developed in the CSHub promise to give those in the building trades better ways to estimate what researchers call the “mileage” of a structure, work that will provide a more accurate picture of a building’s environmental impact over time. The CSHub is also working to provide better life-cycle cost analysis (LCCA) tools, enabling planners to more accurately estimate the financial outlay needed for long-term projects.

- New possibilities for reducing greenhouse-gas emissions in cement production: Making cement is an extremely energy-intensive process that entails heating crushed limestone and clay up to 1,500 degrees Celsius. CSHub engineers have experimented with “doping” cement with a small amount of aluminum in order to decrease the processing temperature and reduce emissions. Also, since reducing the amount of cement powder needed to make concrete could cut emissions, the CSHub is exploring ways to substitute waste materials — such as fly ash from electric coal power plants — for some of the cement powder, while maintaining concrete’s high performance.

The CSHub is already sharing ideas with departments of transportation in several states and with federal agencies. In turn, it is gaining on-the-ground insight into the planning process.

Work planned for the CSHub’s next five-year phase includes additional experiments on the composition of concrete to optimize its durability while minimizing its carbon footprint, and integrating LCA/LCCA thinking into building design. The ultimate goal is to implement the CSHub’s findings into the engineering of infrastructure.