It’s Wednesday evening, so Alexander Slocum is hard at work cooking up a huge batch of spaghetti, green beans and garlic bread in a cramped kitchen on the top floor of MIT’s Building 24. That might not be most people’s image of how an MIT professor spends part of his workday, but it’s something Slocum does every Wednesday for a hungry and appreciative group of a few dozen freshmen.

“Food is a great conversation catalyst,” Slocum explains with a smile as he lays out the dinner on a set of long tables and the students eagerly line up.

The students are all part of the Experimental Study Group, a program celebrating its 40th year at MIT. As an alternative that allows about 50 freshmen to satisfy their General Institute Requirements in an atmosphere of small, personalized classes and peer learning in small study groups, ESG generally provides a sense of community and camaraderie more typical of a small college. Slocum, director of the program since 2002, is also an alumnus of ESG himself.

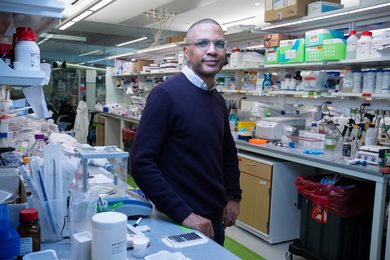

Slocum ’82, MS ’83, PhD ’85, the Neil and Jane Pappalardo Professor of Mechanical Engineering, loves to tinker and build, but most of all he loves to ignite that same passion for creating new devices in other people. His enthusiasm is one reason he was named Massachusetts’ “professor of the year” in 2000, among many awards he has garnered for both research and teaching.

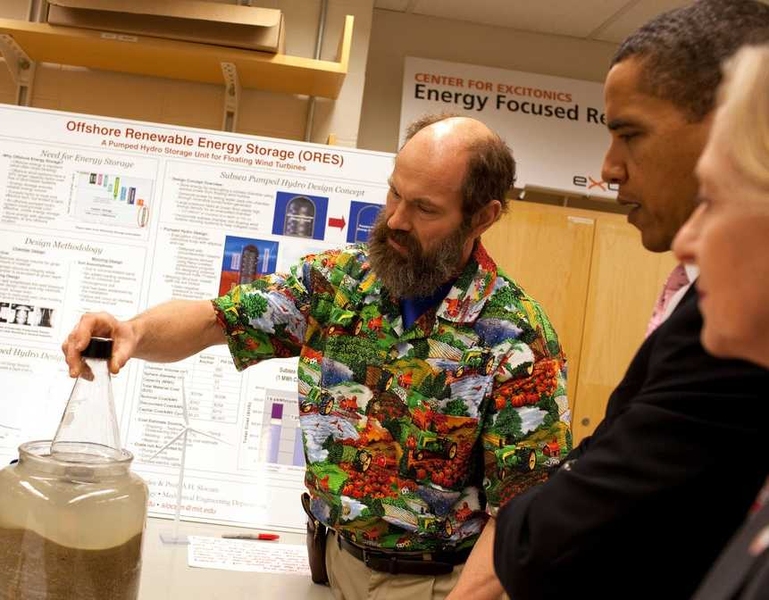

For more than a decade, his was the funny and effervescent voice announcing the play-by-play for MIT’s famed annual student competition of remotely operated robots, held every year as the culmination of class 2.007, “Introduction to Design and Manufacturing.” And when President Barack Obama came to campus last fall and toured labs, Slocum was the researcher who greeted the president wearing (as he usually does) a vibrant Hawaiian shirt and who explained to the commander-in-chief his novel concept to store some of the energy harvested by offshore wind farms.

Devices for doctors

One of the programs Slocum has been especially interested in is a class that he evolved from a class originally created by Prof. Guttag with CIMIT, the Boston-based Center for Integration of Medicine and Innovative Technology. Each year in that class (2.75, “Precision Machine Design”), clinicians and doctors from area hospitals propose to CIMIT a device they wish someone would invent to deal with problems they encounter in their practice.

Students can then pick a problem they would like to tackle, and form teams to develop devices to fill that need. Thanks to U.S. Army sponsorship, each team then gets a budget of about $5,000 to pursue the project. “I have weekly design-review and problem-solving meetings with the student/doctor teams, and the students’ task is to work with the doctor they’ve selected, create strategies and concepts, do a patent search, then do the research and engineering needed to build and test their solution,” Slocum explains.

Several devices developed in that class over the years have won awards (including the MIT $100K business plan competition), and some are being developed as commercial products. Sometimes, the students will advance their designs in a follow-up mechanical engineering class.

Each year, about eight new devices are developed as part of that class, and typically one ends up being described in a paper for a major journal article, and two or three are presented at medical device-design conferences. The class has produced “very important contributions to medical technology,” he says, including a low–cost, single-use robotic system for laparoscopic procedures, a novel needle for injections that can penetrate precisely to the right depth within a blood vessel or organ, and a pressure-sensing syringe.

Robert Sheridan, a doctor at Massachusetts General Hospital who has worked with Slocum’s class, recalls how students in one 2.75 class responded to a problem involving the need for negative-pressure wound therapy — creating a low-pressure atmosphere over a wound to promote healing — with a device that could be used in developing-world locations with limited resources.

“They grasped the clinical problem and developed a creative concept to address the challenge,” Sheridan says. “I had been working in my basement workshop on a concept device, and the students opened my mind to other potential approaches, which have led to the current prototype.” That prototype, further developed by Slocum’s graduate student and original team member Danielle Zurovcik, he says, is now undergoing tests in a rural hospital in Rwanda. In fact, after Zurovcik came back from Rwanda and the Haiti earthquake struck, she garnered support to make more devices and rushed off to help the earthquake victims.

With more than a decade of experience with 2.75, Slocum plans to write up the lessons learned so that mechanical engineering instructors elsewhere can add elements of the class’s distinctiveness to their own. “It might be a useful model for others to adopt bits from,” he says.

The doctors have been quite enthusiastic about the process. Tom Brady, also a doctor from Mass General, says, “the magic is a combination of motivated students and clinicians, unique prototyping facilities, and Alex’s passion for solving medical problems. Alex is the creative force that makes this class work.”

Energy solutions

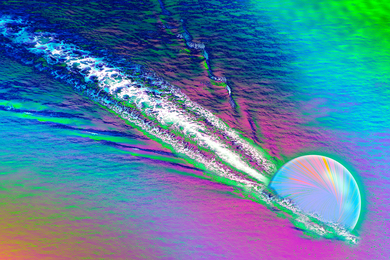

Slocum is also working with students to tackle one of the thorniest problems facing the world: meeting growing energy demand with renewable sources that don’t add greenhouse gases to the atmosphere. His major focus has been a proposal for incorporating an energy-storage system into the mooring structures for offshore floating windmill installations, connected by submerged cables to the grid onshore, so intermittent energy produced by variable winds can be stored on site and delivered just when it’s needed.

The concept involves huge concrete tanks — spheres or cylinders attached to the seafloor beneath the floating windmills — that pump out water when the windmill is producing excess power and then allow water to flow back in, through a generating turbine, when power is needed. It’s a classic pumped hydro system similar to those used for decades with dams and lakes. That’s the concept he demonstrated to President Obama last fall, and Slocum is hopeful that the idea will catch on.

Such a system, he says, could theoretically be used to provide enough power to meet all of the nation’s electricity needs. Offshore wind farms — far enough out to avoid objections about interfering with pristine views — could be arrayed in a few places along the coasts and in the Great Lakes, he says. Wind turbines in a total area of about 100 miles by 500 miles, he estimates, would produce as much electric power as the nation currently uses.

He’s also looking into ways of storing solar power, using molten salts to store the thermal energy for delivery later. With the right policies in place to promote the development and deployment of these technologies along with modular nuclear plants and liquefied coal or biomass for transportation fuels, he says, “The U.S. could essentially be energy independent in 20 years, and that would do more for world peace than anything else. We built the interstate highway system in the interest of national security, so we should be able to build a National Energy System.”

In addition to looking for innovative ways to teach students about science and engineering, and to apply that knowledge to important problems, Slocum is interested in helping them learn how to pass along their knowledge to others. “How do you ever teach someone to become a teacher?” he muses. One way, he suggests, is to have their education be as interactive as possible from the start. Most students who sign up for ESG, for example, come from smaller schools, where they are used to small classes and lots of interaction with their teachers.

And after their freshman year of immersion in that program, many of the students come back as teaching assistants, mentors, seminar leaders and tutors. Slocum thinks having a mix of freshmen, upperclassmen, graduate students, faculty and alums helps to foster the learning process. The more different kinds of people you have around, “the more serendipity can take hold,” he says.

The students tend to appreciate that kind of openness. Nevan Hanumara SM ’06, took Slocum’s 2.75 class a few years ago and now, while working on his doctorate at MIT, has returned as one of the class’s two Teaching Assistants. “He’s a sharer,” he says, “he does not hoard ideas. That’s unusual.” And Slocum encourages an open, exploratory approach: “He’s extremely creative, and also extremely nonlinear and chaotic. You can try stuff really easily.” Those who have taken his classes tend to stay in touch, Hanumara says. “He’s very much interested in our development as people, not just as students.”

One result, he says, is that Slocum has created “a lab full of people who play well together.”

Mechanical engineering graduate student Conor Walsh says simply that 2.75 was “the most interesting class I took at MIT,” and he has continued to work on the project he started in that class as part of his thesis. Working with Slocum and the doctor who suggested that device, he says, “we are developing lots of other devices in the same area as the original product. So in a way, the class spawned a new research area!”

The classes he teaches, Slocum says, where students get a chance to work on something whose real-world application to meet a significant need is clear from the outset, are based on “hard-core mechanical design.” As he finishes scarfing down a plateful of the spaghetti he just prepared, he explains the importance of this kind of hands-on approach to learning: “You can read about cooking, but then you’re still hungry,” he says. “To really satisfy your hunger, you need to get in the kitchen.”

Teaching and tinkering, and teaching how to tinker, are the driving forces for longtime MIT mechanical engineer

Publication Date:

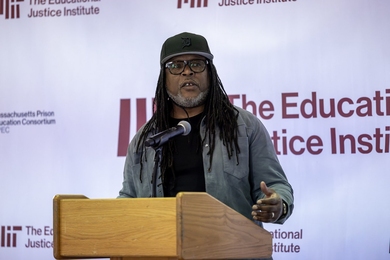

Caption:

Professor Alex Slocum demonstrates the principle behind anchoring proposed energy-storage tanks to the seafloor, as President Barack Obama and MIT President Susan Hockfield look on.

Credits:

Photo courtesy of the White House