On a Friday in mid-November, recent mechanical engineering alumna Elizabeth Bianchini ’18 found herself on stage in front of a rather intimidating audience. She was presenting at the 2018 Collegiate Inventors Competition (CIC) in Virginia, hosted by the National Inventors Hall of Fame.

In the front row was an illustrious panel of judges, including the inventors of the digital camera, Post-It notes, and the pacemaker.

“The coolest part was presenting to some of the most creative minds of our lifetime,” Bianchini recalls. “They saw things that no one else saw until it was obvious how much their inventions changed the world.”

Bianchini presented on behalf of a team of alumni that also includes Kyler Kocher ‘18, Ann McInroy ‘18, and Sam Resnick ’18. The team is continuing work on Rhino, a rotary hammer accessory that could revolutionize the field of masonry. Based on Bianchini’s presentation, the Rhino team was awarded the undergraduate Gold award at the CIC.

“It was my first time presenting about Rhino myself,” she adds. “My excitement was hard to contain. I think my genuine enthusiasm for the product might have been part of why we did so well.”

Rhino was one of the eight products designed and developed by students in last year’s class 2.009 (Product Engineering Processes). The team’s win at the CIC was the culmination of over a year of work by dozens of student team members, faculty, teaching staff, and laboratory instructors.

A fraternity house in disrepair

The group of students who worked on Rhino in 2.009 didn’t have to look far for inspiration. The bricks on team member Sam Resnick’s fraternity house needed repair. Resnick took the lead in trying to find a mason to do the job. He was blown away by the cost and time associated with the project.

The more research Resnick did, the more he realized there was room for improvement. Bricks typically need to be repointed once every 20 years. Currently, the mortar between the bricks is removed using an angle grinder and chisel. Since the radius of grinder wheels is often larger than the vertical joints between bricks, accuracy is a concern and bricks often get damaged. Additionally, the process kicks up large clouds of silica dust, creating health concerns for masons.

After exploring a number of options for products to work on in 2.009, Resnick’s team – Team Orange – decided to tackle brick repointing.

“Brick repointing is everywhere — especially in a place like New England where almost every building you pass is brick, and often historic,” explains Bianchini.

To solve the problem, the team of students decided to focus their attention on rotary hammers as a replacement for grinders. Their research revealed that a rotary hammer can remove mortar in large chunks, nearly eliminating the harmful dust cloud that can envelope masons. It also enables greater speed — which can substantially minimize time and cost associated with brick repointing.

On its own, a rotary hammer would be difficult to control and too inaccurate for use in brick repointing. The team’s invention, Rhino, is an accessory that attaches to the rotary hammer, controls depth of cut, helps guide masons along the mortar joints between bricks, and provides an easy and adjustable interaction for the mason.

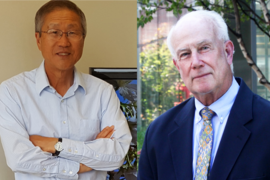

“This project was MIT from the very beginning. Their main motivator was a building right here on campus,” says Warren Seering, the Weber-Shaughness Professor of Mechanical Engineering and one of the 2.009 lab instructors assigned to the Rhino team. “It ties into one of the themes of 2.009, which is to encourage students to identify needs in the world around them.”

Presentation practice

In 2.009, large teams of 15-20 students work together to design and build a working prototype of a new product. Under the leadership of course instructor David Wallace, professor of mechanical engineering, a massive team of faculty, staff, alumni, and Boston area design professionals work to ensure students receive an authentic product design experience.

“A great thing about this class environment is that it’s as close as we can make it to one that students might be in a year from now at a company,” explains Seering. “It’s an excellent setting for active learning of best design practices.”

Part of the authentic design experience is learning to communicate or present about a product. The class culminates in a final presentation in early December where members from student teams present in front of an large, enthusiastic audience in Kresge Auditorium. When it was Rhino’s time to present, team members Hannah Rudoltz, Kyler Kocher, and Ann McInroy took to the stage.

“Presenting at 2.009 was one of the most exciting things I’ve done,” recalls McInroy. “There aren’t many other schools that celebrate engineering in the same way you would a sporting event.”

From the classroom to construction sites

After the confetti was swept away and the semester concluded, it was clear that Rhino was something worth pursuing.

Throughout the design and development process in 2.009, the Rhino team went beyond the walls of MIT and worked with local masons and unions to develop a product best suited to their needs. In spring of this year, a group of Rhino team members continued to work on the business case and perfect the design.

For Bianchini, continuing work on Rhino has helped her further hone non-technical skills that will be essential as she progresses in her career.

“Pushing Rhino beyond the classroom immersed me in the business and legal tasks that fill the gap between project and product,” she explains. “Now I am much more prepared to start my own venture later in my career.”

When it came time to present Rhino and their business case at CIC, over a year of hard work by countless individuals paid off. “Winning at CIC is really exciting because it shows that Rhino is a product that is valuable to a larger audience outside of MIT,” adds McInroy. “The fact we were able to be competitive in such a talented group of inventors is very validating.”

As work on Rhino continues to move forward, Bianchini, McInroy, Resnick, and Kocher will explore business options that can help take Rhino from an idea developed in a classroom to a viable product used at construction sites everywhere.