For decades, materials scientists have worked to infuse the lessons learned from natural proteins into the design of new materials.

However, as the self-assembly process of many proteins remains unclear, our understanding of a material’s properties at a fundamental level and ways it can be translated into real-world use has provided a challenge.

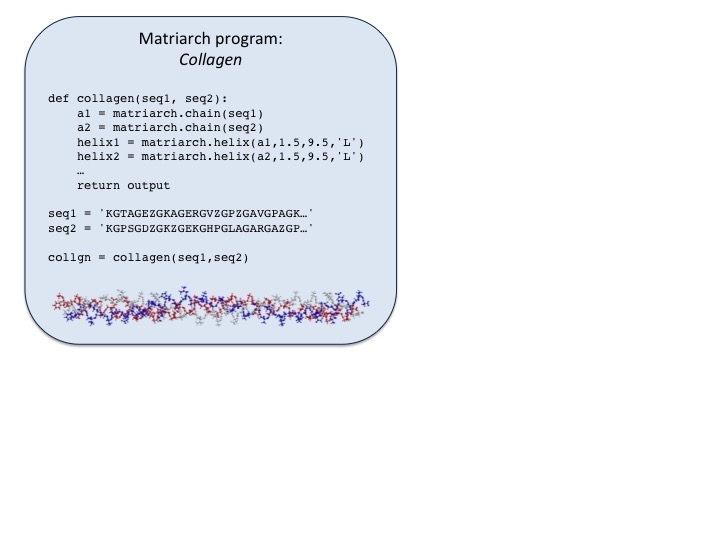

Using a novel mathematical approach, a team of MIT researchers developed a domain-specific programming language for generating custom materials based on a set of design specifications. The software, dubbed Matriarch for “Materials Architecture”, allows users to combine and rearrange material building blocks in almost any conceivable shape.

The work suggests that engineers will be able to reach the next stage of materials design through fundamental control of a protein’s final assembled structure.

“Matriarch could very well be the core of a new molecular design process, where engineering decisions can be made at arbitrary scales,” says Department of Civil and Environmental Engineering (CEE) postdoc Tristan Giesa ’15, co-author of the study. “The idea is to start at ground level. If engineers require a polymer material to have specific properties — strength, resilience, size to name a few — then we need to question what must be done at a fundamental level to achieve these properties.”

With Matriarch engineers can explore what happens to a material’s properties when its architecture changes. Accessible as an open source Python library, the program will ultimately be used as a tool for engineers to quickly discover new materials and design them according to their needs.

“Our description of the material’s architecture is backed up by a rigorous mathematical framework, called category theory,” says David Spivak, co-author and research scientist in the Department of Mathematics. Category theory is a fairly new field of mathematics, focused on structural relationships and compositionality. The assembly process used by Matriarch was specified mathematically as a category-like structure, called an operad.

“We used the math as an inspiration to create a program that identifies the form of these hierarchical protein materials,” says Harvard University sophomore Ravi Jagadeesan, who collaborated as a high school student while enrolled in MIT's Research Science Institute (RSI) program. Jagadeesan, writer of the majority of the software library, explained the code follows the mathematics very closely.

The MIT researchers — Giesa, Spivak, Jagadeesan, and CEE department head Professor Markus Buehler, the study’s senior author — published their findings In ACS Biomaterials Science & Engineering.

A bottom-up design process

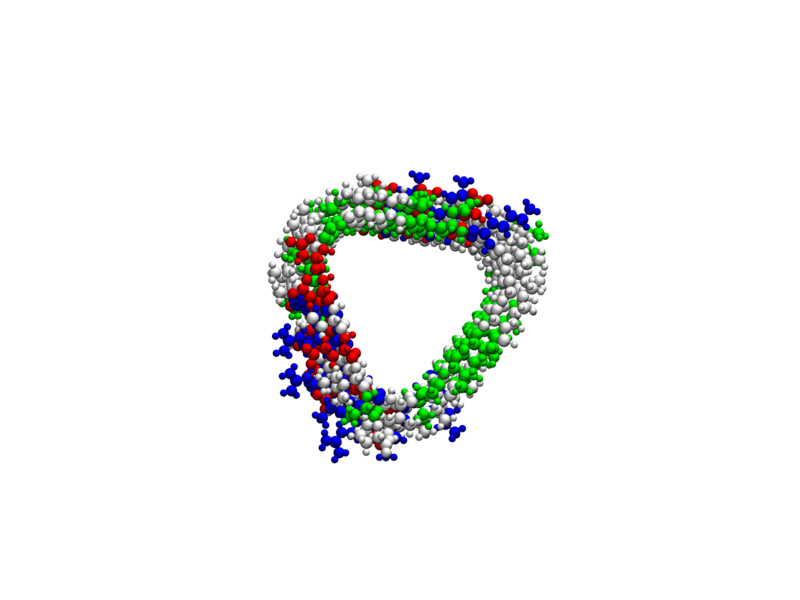

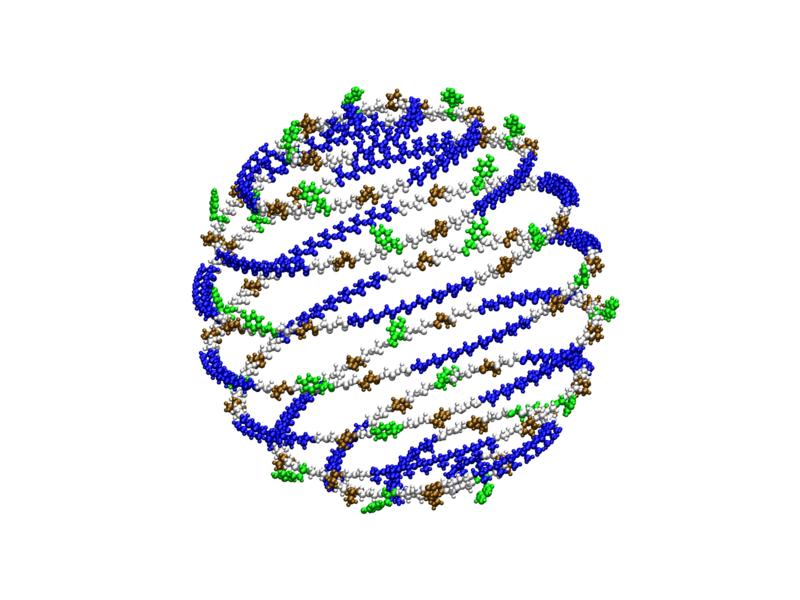

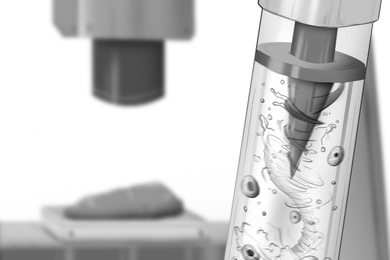

Given a few basic building blocks and instructions, Matriarch builds hierarchical structures of proteins and generates atomic configurations. From these configurations, the program creates Protein Data Bank (PDB) files to be passed to molecular dynamics software.

The engineer can thus use Matriarch to perform building block substitutions, and structural changes, to study their effect on the functionality of a material.

“Our program is specialized on protein-based materials,” says Jagadeesan. “It allows us to replace the sequence of amino acids with anything we choose, and it also allows us to attach different sequences together or bend them in any conceivable shape. This decreases the computational time needed to determine the final structure of the material.”

The team tested their program on collagen protein — one of the most common building materials found in mammals, with a range of potential applications in synthetic design. With Matriarch, they developed a program to form natural triple-helical collagen molecules and alter the amino acid sequence. Mechanical tests on several mutations suggested that natural collagen could be optimized for stiffness and stability.

To perform this study with existing software would have been nearly impossible and time-intensive, says the team. Giesa says that synthesizing novel protein materials, such as collagen mutations, is currently quite challenging, especially in the chemistry lab.

Massively parallel simulation has opened new pathways for materials discovery, but it is still in its infancy. In the meantime, Matriarch will be a useful tool for the fast-growing materials engineering community.

The team is still expanding the functionality of the program, and they plan to systematically explore known proteins and how their subsequences organize themselves as building blocks on a variety of scales. Ultimately, they hope to create an extensible database of structures for engineers to estimate the final configuration that a new material or sequence will have.

“The more this program is used, the more it will gain in efficiency and accuracy,” Spivak says. The self-learning database, after running a stream of simulations, will record the protein’s preferred conformations and store the final structures.

“With this program, we are one step closer to defining the computational tools that form the basis for bottom-up materials engineering and providing the tools to quicken the process of discovering new materials,” Buehler says. “This type of program should be useful to many, will improve our ability to modify natural materials for other engineering applications, and enables engineers to apply category theory to solving real-world problems.”

Jagadeesan acknowledges support by the Research Science Institute program. Spivak acknowledges support by the Air Force Office of Scientific Research and the Office of Naval Research. Buehler and Giesa acknowledge support by the Office of Naval Research, the Army Research Office, and the National Institute of Health (NIH U01), as well as BASF North American Center for Research on Advanced Materials.