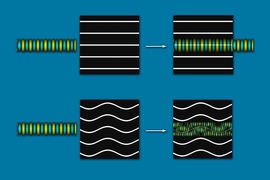

Flexible, layered materials textured with nanoscale wrinkles could provide a new way of controlling the wavelengths and distribution of waves, whether of sound or light. The new method, developed by researchers at MIT, could eventually find applications from nondestructive testing of materials to sound suppression, and could also provide new insights into soft biological systems and possibly lead to new diagnostic tools.

The findings are described in a paper published this week in the journal Physical Review Letters, written by MIT postdoc Stephan Rudykh and Mary Boyce, a former professor of mechanical engineering at MIT who is now dean of the Fu Foundation School of Engineering and Applied Science at Columbia University.

While materials’ properties are known to affect the propagation of light and sound, in most cases these properties are fixed when the material is made or grown, and are difficult to alter later. But in these layered materials, changing the properties — for example, to “tune” a material to filter out specific colors of light — can be as simple as stretching the flexible material.

“These effects are highly tunable, reversible, and controllable,” Rudykh says. “For example, we could change the color of the material, or potentially make it optically or acoustically invisible.”

The materials can be made through a layer-by-layer deposition process, refined by researchers at MIT and elsewhere, that can be controlled with high precision. The process allows the thickness of each layer to be determined to within a fraction of a wavelength of light. The material is then compressed, creating within it a series of precise wrinkles whose spacing can cause scattering of selected frequencies of waves (of either sound or light).

Surprisingly, Rudykh says, these effects work even in materials where the alternating layers have almost identical densities. “We can use polymers with very similar densities and still get the effect,” he says. “How waves propagate through a material, or not, depends on the microstructure, and we can control it,” he says.

By designing that microstructure to produce a desired set of effects, then altering those properties by deforming the material, “we can actually control these effects through external stimuli,” Rudykh says. “You can design a material that will wrinkle to a different wavelength and amplitude. If you know you want to control a particular range of frequencies, you can design it that way.”

The research, which is based on computer modeling, could also provide insights into the properties of natural biological materials, Rudykh says. “Understanding how the waves propagate through biological tissues could be useful for diagnostic techniques,” he says.

For example, current diagnostic techniques for certain cancers involve painful and invasive procedures. In principle, ultrasound could provide the same information noninvasively, but today’s ultrasound systems lack sufficient resolution. The new work with wrinkled materials could lead to more precise control of these ultrasound waves, and thus to systems with better resolution, Rudykh says.

The system could also be used for sound cloaking — an advanced form of noise cancellation in which outside sounds could be completely blocked from a certain volume of space rather than just a single spot, as in current noise-canceling headphones.

“The microstructure we start with is very simple,” Rudykh says, and is based on well-established, layer-by-layer manufacturing. “From this layered material, we can extend to more complicated microstructures, and get effects you could never get” from conventional materials. Ultimately, such systems could be used to control a variety of effects in the propagation of light, sound, and even heat.

George Fytas, professor of materials science and head of the polymer group at the University of Crete, Greece, says this is a "very novel idea, because it induces a directional phonic gap not existing in the layered structure." He adds that this finding "shows how well-established theoretical tools can predict new materials behavior, which is challenging for experimentalists."

The technology is being patented, and the researchers are already in discussions with companies about possible commercialization, Rudykh says.

The research was supported by the U.S. Army Research Office through the MIT Institute for Soldier Nanotechnologies.

Press Contact:

Media Download

*Terms of Use:

Images for download on the MIT News office website are made available to non-commercial entities, press and the general public under a Creative Commons Attribution Non-Commercial No Derivatives license. You may not alter the images provided, other than to crop them to size. A credit line must be used when reproducing images; if one is not provided below, credit the images to "MIT."