One of the reasons food prices have risen sharply is the cost of fertilizer: Nearly 2 percent of the world's energy goes into fertilizer production, which is becoming ever more costly as fuel prices rise.

For decades, chemists have sought less energy-intensive ways to produce ammonia, the main component of fertilizer. The task has proven difficult, however, and only a handful of researchers are still pursuing it.

One of those is MIT's Richard Schrock, a Nobel laureate who has been working on the problem for nearly 30 years. In 2003, he reported the first and only catalytic productions of ammonia from nitrogen gas, using the metal molybdenum as a catalyst.

Schrock, the Frederick G. Keyes Professor of Chemistry, and several of his students are now trying to refine the 12-step reaction to make it more efficient. Their current catalyst can only perform the reaction a few times before it stops working.

"It's not practical yet," said Schrock, who has four members of his laboratory working on the project. He says it may not become practical during his lifetime or beyond, but if it does, the impact on agriculture could be considerable.

"It may not displace Haber-Bosch, but in theory it could be significant," Schrock said.

Haber-Bosch is the industrial process now used to produce fertilizer, which is critical to most large-scale agriculture. Plants need nitrogen to synthesize proteins and DNA, but they can't extract the abundant nitrogen found in Earth's atmosphere. Instead, they rely on nitrogen-fixing bacteria that grow on the roots of some plants, or obtain nitrates and nitrites from the soil.

In the early 20th century, German chemists Fritz Haber and Carl Bosch developed a synthesis that now yields more than 100 million tons of fertilizer annually.

Haber-Bosch is essentially a "brute force" approach to producing ammonia, says Schrock. Nitrogen and hydrogen are combined at extremely high temperatures (500 degrees Celsius) and pressures (300 atmospheres), which requires huge amounts of energy, usually natural gas.

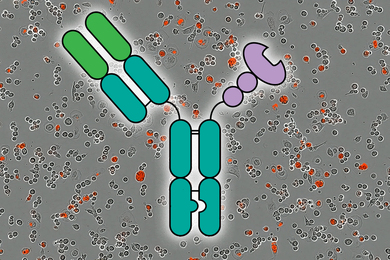

Schrock is taking a different approach -- a step-by-step chemical synthesis, catalyzed by molybdenum, which can occur at room temperature and atmospheric pressure.

"If you could make it work at room temperature and pressure, you don't consume all that energy," he said.

The chemists chose molybdenum as a catalyst because it is most likely the metal used in nature's most efficient ammonia-producing enzyme, Schrock said.

During the 12-step reaction, nitrogen gas molecules attach to the molybdenum catalyst, and protons and electrons are continuously added to the nitrogen atoms. The reduced nitrogen atoms are then picked off the structure and become ammonia. The overall reaction consumes four molecules of nitrogen gas (N2) and produces eight ammonia molecules (NH3).

The process must be painstakingly controlled at each step. The reaction is also made difficult by the fact that gaseous nitrogen is very unreactive. "Nitrogen is very resistant. It's very hard to get it to do what you want," Schrock said.

Schrock says he hopes chemical engineers will get involved with the effort to make the work practical for commercial use, though he believes that using his catalyst to commercially produce fertilizer is still "a long time off."