Seeking "a simple but elegant" solution for a basic health care dilemma in Uganda, Amy Smith, a graduate student in the Technology and Policy Program, used her knowledge of science and engineering to invent a very low-cost, low-maintenance device to help test for microorganisms in water supplies.

The Phase-Change Incubator will also allow health care workers who don't have access to modern medical labs to identify the appropriate antibiotic for treating bacterial infection.

Testing for the presence of microbials, or to see which drugs kill them, usually requires lab workers to incubate or grow the organisms at a constant elevated temperature for about 24 hours. While this is no problem for labs with electricity, those without a reliable energy source just can't do the tests, even if they have the appropriate medical equipment and supplies.

"Here you have a really easy test that's just missing that one piece of hardware. Get that one thing and your possibilities are expanded for use almost anywhere on the planet," said Ms. Smith (SB 1984), who was a Peace Corps volunteer in Botswana from 1986-90, where she taught secondary school and then worked for the Ministry of Agriculture.

Ms. Smith's Phase-Change Incubator makes use of a chemical compound that, once heated to a particular temperature and placed in an insulated container, maintains that temperature for the requisite 24-hour period. A water sample mixed with a growth medium placed inside the insulated container will also remain at that constant temperature, allowing workers to see if bacteria grow.

The beauty is that electricity isn't required for the initial heating, nor for temperature maintenance. If no power is on hand, lab workers can use a wood or coal fire to heat the wax-like chemical to its phase-change temperature.

The chemical compound Ms. Smith uses will melt from the solid to liquid phase at a temperature of 44���C (about 111���F), then hold that near-constant temperature until nearly all of the substance has returned to the solid state. An insulated box keeps it at the heightened temperature longer, about 24 hours.

"Phase-change materials are used for energy storage and release all the time. But this device integrates both energy storage and temperature maintenance," Ms. Smith said.

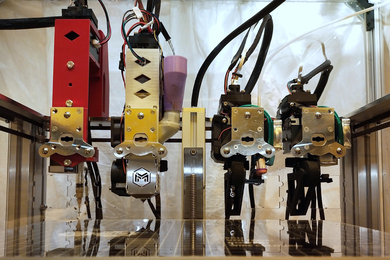

The device consists of a rigid plastic box, about a cubic foot in size, filled with polyurethane insulation. A large aluminum cylinder filled with the chemical fits into the plastic box and can be easily removed for heating. Another aluminum piece holding the samples to be tested (test tubes filled with powder-growth medium, petri dishes, bottles, etc.) fits on top of that cylinder.

Other portable incubators cost about $600 and are battery operated, according to Ms. Smith. She expects the Phase-Change Incubator to cost about $200. It may come equipped with an adapter to allow it to be charged in a car battery. A liquid-crystal top that changes color with the temperature fluctuation will probably be used to alert workers that the chemical compound has reached the appropriate temperature and/or cooled again to room temperature.

Ms. Smith, who periodically teaches an undergraduate course on design for developing countries (SP.753), said she's been thinking of using a phase-change incubator for medical diagnostics since 1991, but just hadn't acted on it.

In 1996, while seeking appropriate design problems for her undergraduate course, she was staying at a guest house in Kampala, Uganda when she met a Canadian working for the African Community Technical Service (ACTS), who was testing drinking water sources for fecal coliforms in rural Uganda.

The next year, one of her undergraduate students, Michelle Berris, went to Africa to work for ACTS. Ms. Berris tested for microbials in water by filling tubes with the water and placing them in her sock to keep them warm.

"I thought, 'Well gosh. I can do better than a pair of socks,'" said Ms. Smith.

So she finally set to work on the incubator. She searched an 855-page chemical-supply catalog looking for materials that had the right melting temperature and weren't toxic or expensive. Then she narrowed the list to less than a dozen and ordered samples for testing.

"It made my daily commute shorter," she said of the lengthy catalog search. Since then, she has founded a company called Amtek and made her first prototype, which is now being tested by ACTS in Uganda. She hopes to get the incubator on the market next year.

Ms. Smith won the B.F. Goodrich Collegiate Inventors competition in September, has entered the device in the Rolex Awards for Enterprise contest and plans to enter the $50K contest at MIT. She has received several grants for work in Africa and has applied for funding from the World Bank for the Amtek project.

She earned the SB in mechanical engineering from MIT in 1984 and the SM and ME in 1995, and is currently working toward the SM in technology and policy. She plans to continue working toward a PhD in mechanical engineering.

In addition to the design course for the developing world, Ms. Smith has also designed and taught a writing seminar on African technology and a new course this fall, "Kaleidoscopic Visions," which teaches students how to build kaleidoscopes out of "PVC tubing and other bits and pieces of things we find lying around," she said. All three courses are taught through the Edgerton Center.

Her interest in the developing world may stem from a childhood year she spent in northwest India with her family. Her father, Professor Arthur Smith of electrical engineering and computer science, taught at a technical institute in a small village in the Rajasthan desert when Amy was six years old. She and her two sisters attended the local boy's school because the girl's school wasn't taught in English.

"I look at things on a global basis," she said. "Technology isn't the only solution, but it can certainly be part of the solution. Policymakers sometimes forget that having the right tool can make all the difference."

A version of this article appeared in MIT Tech Talk on November 24, 1999.