Audio

Pills are by far the most convenient form of cancer treatment, but most oral cancer drugs quickly dissolve in the stomach, delivering a burst of chemicals into the bloodstream all at once. That can cause side effects. It also may limit the drug’s effectiveness because its concentration in the blood may become too low after the initial burst.

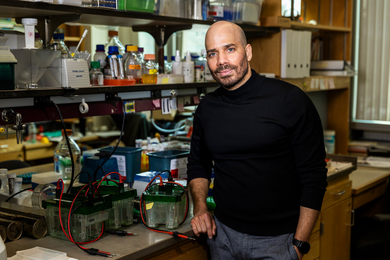

Now, the startup Enzian Pharmaceutics, founded by Aron Blaesi PhD ’14 and former principal research scientist Nannaji Saka ScD ’74, is developing an oral tablet that delivers drugs into the gastric fluid and the blood steadily over time. The company’s tablets use tiny 3D-printed fibers that turn into a gel-like substance when exposed to water. The tablets have been shown to stay in the stomach of animals for up to a day, slowly degrading while releasing the drug in controlled quantities.

The company is currently validating its tablets’ ability to stay in place in a small number of healthy human volunteers. In about a year, it plans to begin testing the technology’s ability to improve the effectiveness and safety of cancer drugs in patients.

“A lot of orally delivered cancer drugs could benefit from this,” says Blaesi, who incorporated the company in 2016. “Right now, soon after someone has taken a cancer drug, its concentration in the blood can be up to 50 times greater than when they are supposed to take the next pill. During the peak, the drug goes into the heart, it goes into the liver, the brain, and it can cause a lot of problems, while at the end of the dosing interval the concentration in the blood may be too low. By taking out that peak and increasing the time the drug is released, we could improve the effectiveness of treatments and mitigate certain side effects.”

In search of innovation

When Blaesi came to MIT, he knew he wanted his mechanical engineering PhD work to form the basis of a company. Early on, as part of the Novartis-MIT Center for Continuous Manufacturing, he worked on manufacturing pills with an injection molding machine that melted and solidified the material, in contrast to the traditional process of compacting powder. He noticed injection molding made the pills far less porous.

“If you put a typical pill into a fluid or into the stomach, the fluid percolates the pores and quickly dissolves it,” Blaesi explains. “That’s not the case when you have an injection molded product. That’s when Dr. Saka, who I met almost daily to discuss my research with, and I started to realize that microstructure is very important.”

The researchers began exploring how different tablet microstructures changed the rate at which drugs are released. For more precision, they moved from injection molding to 3D printing.

Using MIT machine shops, Blaesi built a 3D printer and produced tightly wound microstructures that could carry the drugs. He focused on fibrous structures with space between the fibers, because they would allow gastrointestinal fluid to percolate the pill and dissolve rapidly. He tested the structures in both his Cambridge, Massachusetts, apartment and at MIT’s shared facilities.

Blaesi then experimented with different carrier materials, finding that the higher the molecular weight, the longer it took the pill to dissolve because the material would absorb water and expand before degrading.

“Initially I thought, ‘Oh no, the drug isn’t being dissolved fast enough anymore,’” Blaesi recalls. “Then we thought, ‘Everything has its place.’ This could stay in the stomach for longer because of the expansion. Then it could release the drug over time. We realized this wouldn’t just improve manufacturing, it would improve the product.”

In 2019, Blaesi and Saka published the first paper on their expandable fibrous tablets for prolonged drug delivery. It received a mixed reception.

“Some reviewers said, ‘Research on similar gastroretentive dosage forms has been done for 40 years and no one’s really succeeded,’” Blaesi recalls. “People said, ‘It will never work. Do experiments in animals and then we’ll talk.’”

Blaesi moved back to Switzerland during the Covid-19 pandemic and ran his animal experiments there.

“The reviewers were right: What we had didn’t work,” Blaesi says. “But we adjusted the design and showed we could make the pill stay in the stomach for longer.”

Inside Enzian’s final tablet design, tiny fibers are arranged in a grid. When water flows into the spaces between the fibers, they expand to form a strong gel-like substance that slowly erodes in the stomach, steadily releasing the drug. In animal studies, Enzian’s team showed its technology allowed tablets to remain in the stomach for 12 to 24 hours before being safely excreted.

The team soon found cancer drugs would be a good fit for their technology.

“A lot of cancer drugs are only soluble in acidic solutions, so they can only be absorbed while the drug is in the stomach,” Blaesi explains. “But on an empty stomach, the drug may be in the stomach for just 30 or 40 minutes at present. For a full stomach, it’s a few hours. And because you have a short time to deliver the drug, you need to release a high dose immediately. That shoots up the blood concentration, and if you dose every 12 hours, the concentration is going down during the other 10 hours.”

From the lab to patients

In upcoming human trials, Enzian plans to use its tablets to deliver a drug for prostate cancer that Blaesi says is currently dosed at several hundred milligrams a day. He hopes to get down to about a tenth of that with a better therapeutic effect.

Enzian also believes its technology could improve treatments for blood, skin, and breast cancers.

“This could really be used to improve treatment for a variety of cancers,” Blaesi says. “We believe this is a more efficient and effective way to deliver drugs.”

Maximizing effectiveness and minimizing side effects is also important in clinical trials, where a new drug’s superiority over existing treatments must be shown, and a single adverse event can end its development.

The upcoming move into patients is the culmination of more than a decade of work for Blaesi, who is confident Enzian can deliver on its promise of improving treatments.

“The opportunity is enormous,” Blaesi says. “So many oral cancer drugs have this delivery problem. We still have to do the efficacy and safety studies on patients, but we expect this to be a game changer.”