Audio

China dominates the global supply of lithium. The country processes about 65 percent of the battery material and has begun on-again, off-again export restrictions of lithium-based products critical to the economy.

Fortunately, the U.S. has significant lithium reserves, most notably in the form of massive underground brines across south Arkansas and east Texas. But recovering that lithium through conventional techniques would be an energy-intensive and environmentally damaging proposition — if it were profitable at all.

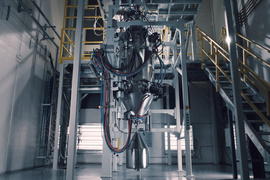

Now, the startup Lithios, founded by Mo Alkhadra PhD ’22 and Martin Z. Bazant, the Chevron Chair Professor of Chemical Engineering, is commercializing a new process of lithium recovery it calls Advanced Lithium Extraction. The company uses electricity to drive a reaction with electrode materials that capture lithium from salty brine water, leaving behind other impurities.

Lithios says its process is more selective and efficient than other direct lithium-extraction techniques being developed. It also represents a far cleaner and less energy-intensive alternative to mining and the solar evaporative ponds that are used to extract lithium from underground brines in the high deserts of South America.

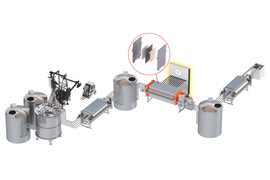

Lithios has been continuously running a pilot system extracting lithium from brine waters from around the world since June. It also recently shipped an early version of its system to a commercial partner scaling up operations in Arkansas.

With the core technology of its modular systems largely validated, next year Lithios plans to begin operating a larger version capable of producing 10 to 100 tons of lithium carbonate per year. From there, the company plans to build a commercial facility that will be able to produce 25,000 tons of lithium carbonate each year. That would represent a massive increase in the total lithium production of the U.S., which is currently limited to less than 5,000 tons per year.

“There’s been a big push recently, and especially in the last year, to secure domestic supplies of lithium and break away from the Chinese chokehold on the critical mineral supply chain,” Alkhadra says. “We have an abundance of lithium deposits at our disposal in the U.S., but we lack the tools to turn those resources into value.”

Adapting a technology

Bazant realized the need for new approaches to mining lithium while working with battery companies through his lab in MIT’s Department of Chemical Engineering. His group has studied battery materials and electrochemical separation for decades.

As part of his PhD in Bazant’s lab, Alkhadra studied electrochemical processes for separation of dissolved metals, with a focus on removing lead from drinking water and treating industrial wastewater. As Alkhadra got closer to graduation, he and Bazant looked at the most promising commercial applications for his work.

It was 2021, and lithium prices were in the midst of a historic spike driven by the metal’s importance in batteries.

Today, lithium comes primarily from mining or through a slow evaporative process that uses miles of surface ponds to refine and recover lithium from wastewater. Both are energy-intensive and damaging to the environment. They are also dominated by Chinese companies and supply chains.

“A lot of hard rock mining is done in Australia, but most of the rock is shipped as a concentrate to China for refining because they’re the ones who have the technology,” Bazant explains.

Other direct lithium-extraction methods use chemicals and filters, but the founders say those methods struggle to be profitable with U.S. lithium reserves, which have low concentrations of lithium and high levels of impurities.

“Those methods work when you have a good grade of lithium brine, but they become increasingly uneconomical as you get lower-quality resources, which is exactly what the industry is going through right now,” Alkhadra says. “The evaporative process has a huge footprint — we’re talking about the size of Manhattan island for a single project. Conveniently, recovering minerals from those low concentrations was the essence of my PhD work at MIT. We simply had to adapt the technology to the new use case.”

While conducting early talks with potential customers, Alkhadra received guidance from MIT’s Venture Mentoring Service, the MIT Sandbox Innovation Fund, and the Massachusetts Clean Energy Center. Lithios officially formed when he completed his PhD in 2022 and received the Activate Fellowship. Lithios grew at The Engine, an MIT startup incubator, before moving to their pilot and manufacturing facility in Medford, Massachusetts, in 2024.

Today, Lithios uses an undisclosed electrode material that attaches to lithium when exposed to precise voltages.

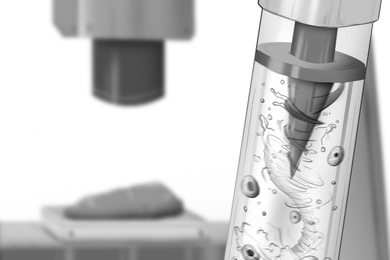

“Think of a big battery with water flowing into the system,” Alkhadra explains. “When the brine comes into contact with our electrodes, it selectively pulls lithium while rejecting all the other contaminants. When the lithium has been loaded onto our capture materials, we can simply change the direction of the electrical current to release the lithium back into a clean water stream. It’s similar to charging and discharging a battery.”

Bazant says the company’s lithium-absorbing materials are an ideal fit for this application.

“One of the main challenges of using battery electrodes to extract lithium is how to complete the system,” Bazant says. “We have a great lithium-extraction material that is very stable in water and has wonderful performance. We also learned how to formulate both electrodes with controlled ion transport and mixing to make the process much more efficient and low cost.”

Growing in the ‘MIT spirit’

The U.S. Geological Survey last year showed the underground Smackover Formation contains between 5 and 19 million tons of lithium in southwest Arkansas alone.

“If you just estimate how much lithium is in that region based on today’s prices, it’s about $2 trillion worth of lithium that can’t be accessed,” Bazant says. “If you could extract these resources efficiently, it would make a huge impact.”

Earlier this year, Lithios shipped its pilot system to a commercial partner in Arkansas to further validate its approach in the region. Lithios also plans to deploy several additional pilot and demonstration projects with other major partners in the oil and gas and mining industries in the coming years.

“After this field deployment, Lithios will quickly scale toward a commercial demonstration plant that will be operational by 2027, with the intent to scale to a kiloton-per-year commercial facility before the end of the decade,” Alkhadra says.

Although Lithios is currently focused on lithium, Bazant says the company’s approach could also be adopted to materials such as rare earth elements and transition metals further down the line.

“We’re developing a unique technology that could make the U.S. the center of the world for critical minerals separation, and we couldn’t have done this anywhere else,” Bazant says. “MIT was the perfect environment, mainly because of the people. There are so many fantastic scientists and businesspeople in the MIT ecosystem who are very technically savvy and ready to jump into a project like this. Our first employees were all MIT people, and they really brought the MIT spirit to our company.”