After months of preparation, MIT is planning to break ground this month on an upgrade project that will revitalize its Central Utilities Plant (CUP), a distributed energy resource (DER) that powers the campus microgrid with thermal and electric energy. The CUP upgrade is essential to the Institute’s sustainability goals and will improve campus resiliency by creating an enhanced, more efficient, more flexible power system. This in turn supports efforts in Massachusetts and neighboring states to build overall resiliency across the Northeast.

How does the project support these efforts? Improved campus resiliency at MIT takes pressure off the region’s utility grid — a system experiencing increasing demands and the growing frequency of severe weather events. The flexibility of MIT’s system is based in part on the fact that the campus microgrid can be coupled with the regional grid or can run independently as needed. MIT’s ability to operate on self-generated power in emergency situations will help local utilities meet customer demand and provide more reliable services.

“Localized distributed energy resources are becoming more crucial to any forward-thinking energy strategy,” says Ken Packard, director of utilities at MIT. “When it’s upgraded, MIT’s smart microgrid will enable MIT to take most or all of our load off the regional grid when necessary. This reduces pressure on the region’s infrastructure and at the same time makes it possible for us to protect the campus from a superstorm or other power outage event. In addition, we are optimizing the plant to provide the cleanest possible energy, whether we are generating it on campus or receiving it from the grid, especially as the grid becomes less carbon intensive.”

A cleaner source for on-campus power

Since 1995, the CUP has relied on a single 22-megawatt (MW) gas turbine — like the turbine that powers a jet engine — to produce electrical and thermal energy simultaneously through cogeneration, a combined heat and power process. The upgrade project will replace this aging turbine with a new one and install a second 22 MW gas turbine, each equipped with a heat recovery steam generator. In addition, the upgrade includes changing fuel use scenarios for five existing boilers to eliminate the use of No. 6 fuel oil on campus and equip them to use cleaner fuels such as natural gas or No. 2 fuel oil. The plant will switch to using natural gas for all normal operations, relegating fuel oil to backup emergency use only. Both new turbines are projected to be in service by 2020.

As it revitalizes the CUP and returns it to state-of-the-art condition, MIT expects to build campus resiliency by improving energy efficiency and increasing on-campus power capacity in support of MIT’s robust research activities. Resiliency is also built into the design of the upgrade, which anticipates evolving technologies and will enable the plant to incorporate future innovations that enhance campus sustainability.

The CUP’s efficiency and environmental gains will result from the installation of new and upgraded equipment as well as the switch to natural gas and the elimination of fuel oil use (except for emergencies). State-of-the-art emissions controls will contribute to the improvements. Starting in 2020, regulated pollutant emissions are expected to be more than 25 percent lower than 2014 emissions levels, and greenhouse gas emissions will be 10 percent lower than 2014 levels, offsetting a projected 10 percent increase in greenhouse gas emissions due to energy demands created by new buildings and program growth.

The Institute’s preparation for the upgrade project involved a rigorous permitting process that included working with the Massachusetts Department of Environmental Protection (DEP) and Executive Office of Energy and Environmental Affairs. On June 21, the project passed a major milestone when the DEP issued the final permit and plan approval stating that the new plant complies with state and federal air quality standards, enabling the project to move forward to construction.

Envisioning the upgraded plant

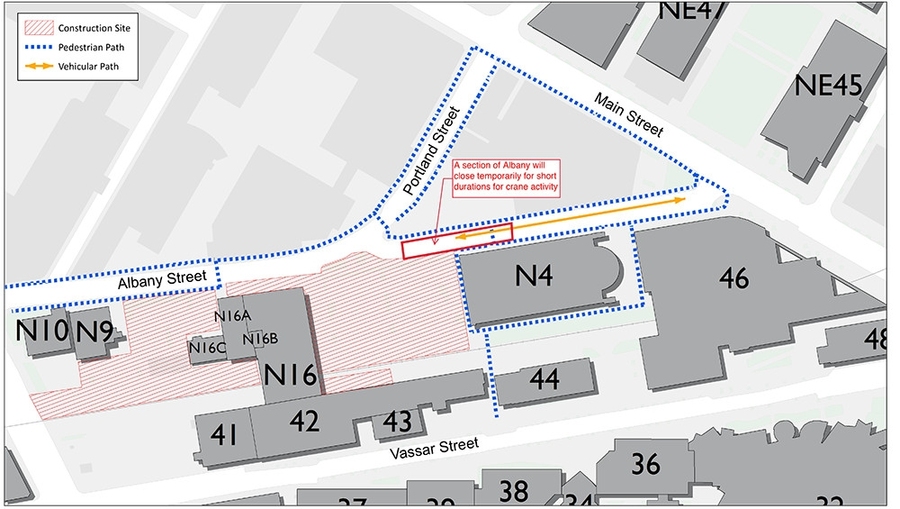

Upgrade plans for the CUP include building a new addition to the plant on the site of an existing parking lot along Albany Street (N10 Annex Lot). Carefully designed by Ellenzweig to fit the architecture of the surrounding community, the addition’s exterior will include windows that allow passersby to view the cogeneration plant’s operations.

Housing new equipment, the addition will connect with the existing plant via two overhead bridges, one of which will contain a control room that enables operators to run both sections of the plant from a single location. A presentation space in the new addition will enhance the CUP team’s ability to engage with students and researchers on living lab activities and host learning opportunities for the broader community.

As part of the project, the streetscape along the perimeter of the plant will be improved with new lighting on public walkways as well as new public seating, bicycle racks, trees, and other plantings. The enhancements are designed to invite pedestrian traffic, creating a stronger connection between the main campus and the north campus.

The project also includes a rooftop system that will capture rainwater for use in the facility’s cooling towers, easing the burden on Cambridge’s storm water system. The perimeter site area will drain into rain gardens and through groundwater recharge.

“What’s unique about the design of this building is that it integrates an elegant exterior with the fundamental needs of the process and machinery inside,” notes Dave Brown, program manager of Utility Projects. “The architects worked closely with the Power Group at Vanderweil Engineers to create a complex solution that looks attractive and simple from the street. Inside, we’ll have very high-tech equipment and state-of-the-art controls, all fitting together in a way that accommodates the process and incorporates innovations. Outside, the pedestrian path is enhanced, and you’ll have the ability to walk by, look in, and see the plant in action.”

Construction overview and activities

The CUP upgrade project team is expecting to begin construction this month. Key equipment is scheduled for installation in 2018, and testing and commissioning is planned for late 2019. Full operation of the upgraded plant is projected for 2020.

In preparation for construction, the N10 and N10 Annex parking lots are closing, with permit holders relocated to other lots on campus. Construction activities expected to start in the next few weeks and continue through the spring of 2018 include site preparation and enabling, site excavation, utility work, and the construction of foundations. Pedestrian and vehicular navigation around the site will be maintained by short detours around the edge of the construction site. As the CUP upgrade project progresses, lane closures on the section of Albany Street in front of the construction site will be required for short periods of time. Police details will be on site to direct and maintain the flow of traffic and two-way access to the Albany Street garage will be maintained throughout construction.

Community members with questions about the CUP upgrade project may contact the project team. Updates will be posted to the Powering MIT project site.