MIT is determined to support its research and other world-changing activities with efficient, reliable power and utilities. To achieve this in the context of its recent commitment to at least a 32 percent reduction (by 2030) in greenhouse gas emissions, MIT is upgrading its on-campus cogeneration plant — a key step in developing an energy strategy that makes climate change mitigation a top priority.

For the past 20 years, the Institute has produced a portion of its own power on campus through a combined heat and power process, also known as cogeneration — a highly efficient method of generating electrical and thermal power simultaneously. The cogeneration (or “cogen”) facility in the Central Utilities Plant (CUP) currently provides electricity, steam heat, and chilled water to more than 100 buildings on MIT’s Cambridge campus. But the 21-megawatt natural gas turbine at the heart of the cogen plant has been running since 1995 and is nearing the end of its useful life.

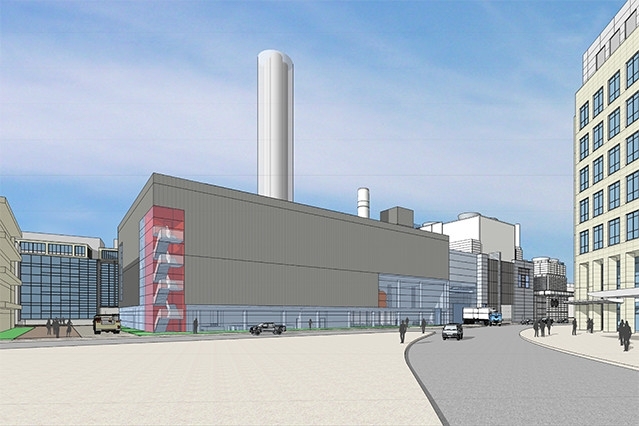

The CUP Second Century Project will replace the existing cogeneration turbine with a new turbine, install a second turbine, and complete the chilled water plant upgrades started in 2008. The project also reflects MIT’s efforts to keep moving toward a more sustainable campus.

Although it may seem like a simple change, the CUP Second Century Project is an integrated solution based on a rigorous process of study and analysis that stretches back more than 10 years. Beginning in 2003, MIT began evaluating a wide range of options that could provide power, heat, and cooling to the campus once the existing turbine was ready for replacement. The evaluation process showed that an upgrade of the on-campus cogeneration system, compared with various methods of procuring electricity and/or steam from off-campus sources, was the most effective, appropriate, and sustainable way to meet MIT’s near-future energy needs as it advances its robust research and teaching initiatives.

The launch of this project will enable MIT to retire the existing cogen turbine in 2020, by which time both new turbines and heat recovery systems will be up and running in an enhanced facility at the existing plant’s location between Vassar and Albany Streets. With new and upgraded equipment in place, MIT will eliminate the use of fuel oil in campus power generation by 2020, except in emergencies.

“Cogeneration helps MIT cut down on pollutants and greenhouse gas emissions,” says Don Holmes, director of maintenance and utilities. “Our goal is to create an upgraded power system that will improve the resiliency of the campus and support future research while also conserving energy and reducing our impact on the environment.”

A more resilient campus and community

During superstorm Sandy in 2012, Princeton University’s 15.5-megawatt cogeneration plant served as the sole power source for many of its buildings and residences. In the days following the storm, New York University’s cogeneration plant maintained partial power on campus, enabling NYU to provide a command center for emergency workers.

Similarly, MIT’s upgraded cogen plant will increase the resiliency and durability of the campus, enabling it to remain operative during an area-wide power loss or natural disaster. Campus operability in these situations will reduce the burden on local utilities, first responders, and the Cambridge community as a whole.

“With the plant upgrades, we will improve power reliability and overall cycle efficiency, and we will create a system that is flexible enough to incorporate new innovations,” says Ken Packard, director of utilities. “This system will keep MIT operating regardless of access to electricity from our outside utility partner.”

The new cogeneration turbines can be started even in the absence of external power and will continue supplying heat and electricity to campus. In addition, the upgraded plant’s equipment will be designed and sited specifically to keep key components above the anticipated 500-year flood level, enabling the facility to maintain operations during severe weather conditions. This increase in power security and capacity will safeguard campus residences and protect vital research efforts.

As part of the upgrade, MIT will also provide energy provider Eversource with a location inside the plant for a new gas regulator station that will provide additional capacity and more reliable service for this area of Cambridge. (MIT’s existing dedicated transmission gas pressure line will support the new regulator station.) With this access, Eversource can offer uninterrupted service to local neighborhoods and can develop and expand local service without digging up city streets and replacing pipes.

A sustainable approach

The necessary upgrade of the existing system presents MIT with a valuable opportunity to renew and strengthen its commitment to energy conservation and effective climate change mitigation.

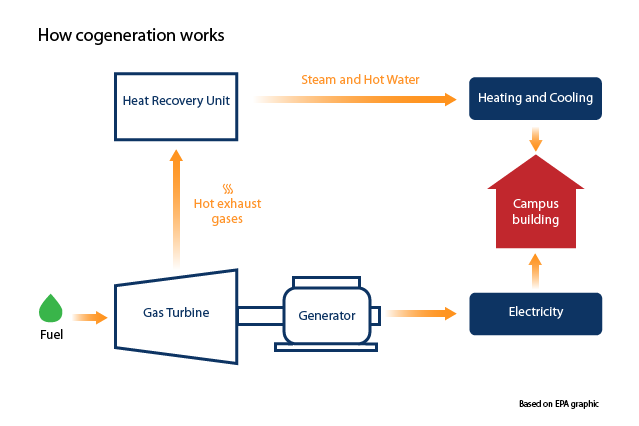

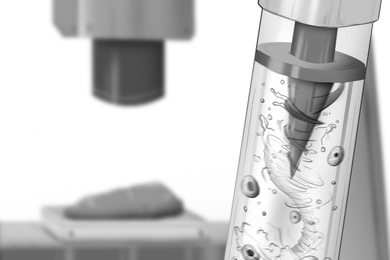

As a process for producing both heat and power, cogeneration is one of the cleaner and most affordable options available, achieving high efficiency by using one fuel to generate two types of energy. In MIT’s existing cogen plant, natural gas is used to produce both electric and thermal energy. The 21-megawatt gas turbine generates electricity, and a heat recovery steam generator captures the waste heat from the turbine’s exhaust. The resulting captured steam is used for heating and cooling (via chillers that are driven by steam turbines).

The existing cogen plant has already earned its stripes in a variety of ways.

- Since the plant came online in 1995, MIT has achieved annual reductions in greenhouse gas emissions of 15-20 percent compared with conventional energy sources (purchasing all of its electricity from the grid, and using natural gas boilers to generate steam).

- During the 20 years since then, the Institute has avoided an average of 68,000 metric tons of carbon dioxide emissions each year compared with conventional energy sources, according to U.S. Environmental Protection Agency (EPA) models.

- In 2013 alone, the greenhouse gas emissions avoided by MIT were equal to the emissions generated by the electricity use in more than 8,000 single-family homes over a period of one year.

- The existing plant has used close to one-third less fuel than conventional energy sources would have consumed to generate the same amount of electricity and steam.

- In recognition, MIT’s cogen facility received the Energy Star Combined Heat and Power Award in 2002 for environmental excellence from the EPA and U.S. Department of Energy.

The enhanced power system, anchored by two new 22-megawatt natural gas turbines, will serve MIT’s campus for at least the next 20 years. “Our energy strategy is moving toward a more sustainable approach,” notes Israel Ruiz, MIT's executive vice president and treasurer. “The plant upgrade is just one of many steps we are taking to create a more sustainable campus.”

Key features of the Second Century Project include:

- The upgraded plant will use natural gas for all normal operations, lowering MIT’s regulated pollutant emissions more than 25 percent from 2014 emissions levels.

- Modeling shows that in 2020, even though energy consumption on campus will have increased due to new buildings and other demands, the upgraded plant’s greenhouse gas emissions will be 10 percent lower than 2014 emissions.

- The two new turbines will be cleaner and more efficient than the plant’s existing turbine. The turbines will use state-of-the-art emissions controls, including two different catalysts that will reduce the generation of NOx (nitrogen oxide) emissions by 90 percent as compared to the current system.

- MIT has finalized a gas supply agreement with Eversource, which will enable the cogeneration plant to run entirely on natural gas by 2020 with the exception of emergencies and testing. This will enable MIT to further reduce emissions.

- After the heat recovery steam generation process, the exhaust stream will be routed through a condensing economizer (hot water) coil that captures additional waste heat. MIT plans to distribute the resulting heated water around campus through an expanded medium temperature hot water loop, to provide heat and hot water to MIT buildings. When that system is established and the coil is capturing heat, the temperature in the plant stack will be lowered. This will raise the efficiency of the plant’s process and enable MIT to use less natural gas.

- In addition, MIT will modify its three older existing boilers to make them compatible with cleaner #2 fuel oil, so they can use that fuel should our gas supply be interrupted. This will eliminate the use of #6 oil on campus by 2019. Cleaner fuel means fewer particulates in the air. (MIT’s two newer boilers already use #2 fuel; on the rare occasions when fuel oil is required for testing or during an emergency, each of the boilers will be able to operate using the cleaner fuel.)

- New cooling towers with high-efficiency drift eliminators will also help reduce particulate emissions and conserve water. Water droplets captured from the towers’ air streams will be redirected downward, preventing the droplets from escaping from the tower.

“MIT is taking great strides forward with the upgrade of its system,” notes Richard Amster, director of campus construction. “As a research university, MIT will continue to evolve, and we need the capacity to pursue novel technologies and paths of innovation. At the same time, we are aware of the global need to conserve energy and address climate change. By increasing the reliability and sustainability of our campus power system, we are positioned to responsibly support future research activities and buildings.”

Even more important, MIT’s continued use of cogeneration enables the Institute to create a flexible power system that can adapt and evolve in response to advances in the energy field. The plant is central to the Institute’s efforts to ensure that climate action and energy efficiency are an inherent part of planning for the future of the campus.

“With this system,” says Packard, “MIT will be better positioned to explore additional sustainability and efficiency measures, and we’ll be able to incorporate emerging energy technologies as they become available. We are collaborating with the Office of Sustainability on an energy strategy that defines our goals for the future, including at least a 32 percent reduction of campus greenhouse gas emissions by 2030. Cogeneration is the bridge that will get us there.”

Project site and timeline

The current site of MIT’s cogeneration plant will be adapted to accommodate the installation of the new gas turbines while the existing turbine continues to function. MIT is planning to bring the first new turbine on line in the summer of 2019 and have both turbines operable by late 2020, at which time the old turbine will be retired.

Over the next year, MIT will work with several agencies through the permitting process for the plant project. As a first step, MIT will submit a permit request to the Massachusetts Department of Environmental Protection.

Project updates and permitting documents will be posted to a new website dedicated to the Second Century Project. Visit the site to learn about the permitting processes and goals.