According to the World Food Program (WFP), nearly one-third of food produced for human consumption is lost or wasted, and over half of that food waste happens during production, post-harvest handling, and storage.

Post-harvest storage technologies like silos and hermetic bags have been successfully developed and piloted with smallholder farmers over the past several decades to mitigate food loss caused by improper storage, but none of these technologies have reached significant scale — until now. Within just a couple of harvests, over 110,000 farmers have chosen to participate in WFP’s post-harvest loss reduction programme, with even larger aspirations ahead.

MIT researchers have now released a new report evaluating various post-harvest storage technologies sold as a part of a special operation run by the World Food Program in Uganda to better understand which technologies are best poised for scale.

The report, “Scaling Adoption of Hermetic Post-Harvest Storage Technologies in Uganda,” details the study design and findings of the latest experimental evaluation implemented by the Comprehensive Initiative on Technology Evaluation (CITE), a program supported by the U.S. Agency for International Development (USAID) and led by a multidisciplinary team of faculty, staff, and students at MIT.

Launched at MIT in 2012, CITE is a pioneering program dedicated to developing methods for product evaluation in global development. CITE researchers evaluate products from three perspectives, including suitability, or how well a product performs its purpose; scalability, how well the product’s supply chain effectively reaches consumers; and sustainability, or how well the product is used correctly, consistently, and continuously by users over time.

Identifying the most affordable, available technologies

To conduct this evaluation, MIT researchers worked closely with the World Food Program, the United Nations agency focused on ending hunger by providing humanitarian aid and building food security. In 2014, the World Food Program established a special operation to train Ugandan farmers in post-harvest storage and introduce them to post-harvest technologies, while also supporting Uganda’s private sector to develop business models for post-harvest loss reduction.

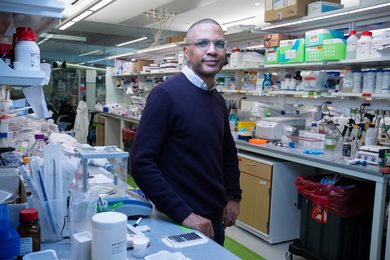

“The World Food Program offered four products to over 16,000 farmers at a subsidized price: metal silos in two sizes produced by local artisans, plastic silos produced by a local manufacturer, and hermetic bags, which were imported,” explains Jarrod Goentzel, CITE scalability lead and director of the Humanitarian Response Lab. “We wanted to understand how these products compared in cost, availability, and value to the farmer. And we sought to identify opportunities for improvements in local supply chains to better deliver these products in the future.”

MIT researchers found that plastic silos produced by a local manufacturer showed the most potential, with a strong value proposition to farmers and capacity to scale production. However, the cost structure as reported by the manufacturer indicated they were selling the silos at a loss.

“After the study, the World Food Program worked with a new manufacturer to reduce the cost,” Goentzel says. “They redesigned the product so silos could be nested for stacking to increase transportation efficiency.”

Metals silos produced by local artisans were attractive to farmers, but were less available than other products. Artisans that employed skilled labor and utilized manufacturing equipment had higher productivity, indicating that local production could be competitive through labor training and capital investment. Researchers found imported hermetic bags were affordable but offered low margins for the sales channel partners.

“Because local artisans were not consistently able to produce silos at the scale needed, the World Food Program decided to source their metal silos from a central manufacturer in Kampala. Still, there’s potential to be explored in the local artisan model. It will just take longer to scale up,” Goentzel explains.

Based on findings from the study, the World Food Program also changed the distribution of post-harvest technologies. Before, the organization arranged for transport directly, and now, they instead arrange for manufacturers to transport products to local distributors or agro dealers for distribution to farmers.

Another important aspect of the study was the training on improved handling and storage practices that accompanied the sale of post-harvest technologies.

“The special purpose trainings facilitated by the World Food Programme in this initial program were expensive, but important: They became the ‘power users’, essential for effective word-of-mouth marketing. It’s key that post-harvest training become part of the business model for private sector actors and incorporated into local extension services in the future,” Goentzel says. “There is already interest from distributors and agro dealers, as well as from the Ugandan government.”

Adaptive methods, adaptive organizations

To conduct this study, MIT researchers used mixed methods, employing empirical research — surveys, semi-structured interviews, and even hypothetical behavioral experiments — to gather data that informed an analytical model. Combining empirical research with modeling helped researchers better understand the current trajectory in farmer adoption and identify the most critical factors in scaling faster.

“Unlike the products themselves, you can’t bring supply chains into the lab,” Goentzel explains. “Market facilitation by a development organization like the World Food Program provides an important laboratory in developing effective business models.”

Goentzel says this research also shows how even large organizations like the World Food Program can be adaptive and flexible, with a focus on learning.

“Our partners at the World Food Program, in particular their Global Post-harvest Knowledge and Operations Center, are a really good example an organization that aims to quickly learn, adapt, and iterate. That’s a cycle you want to have as part of successful market facilitation, particularly in emerging market contexts,” he says.

Now, the World Food Program is working on rolling out similar post-harvest storage initiatives in Tanzania, Rwanda, Burundi, Sudan, South Sudan, Burkina Faso, Mali, Zambia, and Zimbabwe.

“From the onset, CITE has been a core partner of the World Food Program’s work to achieve massive scaling of hermetic storage with smallholder farmers,” says the World Food Program’s Head of Global Post-Harvest Knowledge and Operations Centre Brett Rierson. “Our collaboration goes far beyond the design of evaluation tools, or having them interview farmers: MIT’s practical, hands-on approach has had a direct impact as WFP continues to refine our work to reduce post-harvest losses across Africa.”

CITE’s research is funded by the USAID U.S. Global Development Lab. CITE is led by Principal Investigator Bishwapriya Sanyal of MIT’s Department of Urban Studies and Planning, and supported by MIT faculty and staff from D-Lab, the Priscilla King Gray Public Service Center, the Sociotechnical Systems Research Center, the Center for Transportation and Logistics, the School of Engineering, and the MIT Sloan School of Management.

In addition to Goentzel, co-authors on this report include CITE researcher Jennifer Green and research assistants Mark Brennan, Emily Gooding, and Jonars Spielberg; Jaime Andrés Castañeda, a researcher at Universidad del Rosario in Colombia; and Mike Veatch at Gordon College.