Researchers in the lab of Antoine Allanore, the Thomas B. King Assistant Professor of Metallurgy at MIT, have been working on potash alternatives for three years. In a paper published Oct. 20 in PLOS One, Allanore group postdoc Davide Ciceri demonstrates through microfluidic experiments that feldspar interacting with an acid solution can release sufficient quantities of potassium for agriculture.

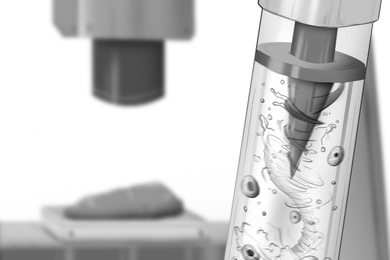

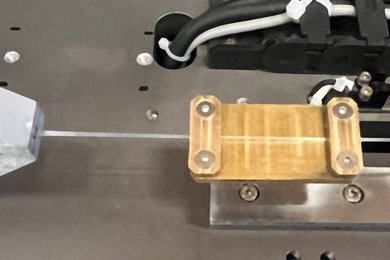

Prior studies of the leaching rate for potassium ions from feldspar used one of two methods, either batch apparatuses or flow-through apparatuses. Neither adequately mimics the natural soil environment around the roots of a plant, Ciceri contends. He developed a microfluidic device to measure leaching from a thin section of feldspar, on a time and size scale that mimics natural pores in soil better than previously reported. "We think it's a kind of pioneering work, which could lead to several additional developments," Ciceri says. "Basically, any type of liquid/solid interactions has the potential to be investigated with this device. Soil science, petrology, and geology will benefit from this device," he adds.

Measuring the rate

The primary objective of the study was to determine how fast potassium is leached from feldspar. By precisely measuring quantities of potassium leached from thin sections of feldspar, Ciceri establishes this leaching is consistently higher in his microfluidic set up than in prior studies conducted with conventional batch or flow-through apparatus, suggesting potassium availability from feldspar will be higher in soils than conventional studies would suggest.

Potassium feldspar is a silicate mineral, which also contains silicon, oxygen, and aluminum. "Results obtained from such a device challenge the notion that silicate minerals cannot be used as alternative fertilizers for tropical soils," the researchers report in "Microfluidic Leaching of Soil Minerals: Release of K+ from K-Feldspar." Microfluidic experiments have shown that Brazilian feldspar releases enough potassium to compete with potash for certain agricultural uses, if the flow and chemical conditions are right. Allanore is senior author. Terrativa Minerals, a commercial company, funded the research.

Potash symposium

Ciceri's paper fits into the context of broader research in the Allanore lab to develop alternatives to potassium chloride (KCl) fertilizer for southern hemisphere farming, where potassium salts imported from the global north are costly. Allanore is convening the first International Workshop on Alternative Potash in Room 4-237 on the MIT campus for three days, Nov. 10-12, with a day of public sessions on Nov. 11. The event is co-sponsored by MIT Environmental Solutions Initiative.

Separately, a potash alternative developed in Allanore's lab has shown good results in greenhouse tests on maize by the Brazilian Agricultural Research Corp. (Embrapa) in Brazil. "They were extremely happy," Allanore says. Field trials are underway.

Experimental methods

Ciceri studied potassium-bearing feldspar obtained from syenite, a natural rock. The sample was from Brazil. Syenite can be ground into a fine powder, known as "stonemeal" for use as a fertilizer, but the microfluidic studies were conducted on thin sections. He also measured the ratio of inertial forces to viscous forces in the microfluidic system.

"In the microfluidic system where the length scale is small, viscosity dominates over inertia, and this is also known as the laminar flow regime. When you are in the laminar flow regime, there is no turbulence," Ciceri says. He also suggests his microfluidic apparatus could have broader application than the current study, including petrology. "We have proved that we have a new technology, which comes in the form of a microfluidic device, to investigate leaching ... of minerals," he explains. "We think the device can have a much broader spectrum of application in other fields. For example, for the observation of shale minerals and their porosity, which has applications in the extraction of natural gas, or the leaching of glasses used for the storage of nuclear wastes."

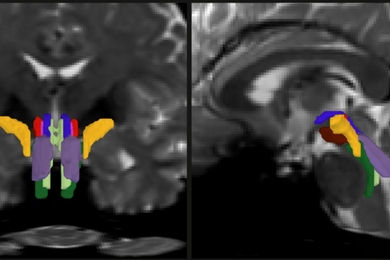

"This microfluidic research by Ciceri and Allanore is very exciting," says Dean L. Hesterberg, the William Neal Reynolds Distinguished Professor of Soil Chemistry at North Carolina State University, who was not involved in the research. "Electron and X-ray imaging at the microscale reveals very diverse, natural spatial heterogeneities in the chemical composition of minerals and soil particles, but we do not understand how these heterogeneities affect reaction kinetics. The microfluidic technique should provide great opportunities to gain new insights on microscale and pore-scale geochemical processes in soils that affect nutrient and contaminant mobilization and uptake by plants."

Reconsidering stonemeal

In a supplementary report, Ciceri estimates the amount of feldspar that would be necessary to sustain the growth rate of a real commercial crop, such as leeks. The strongly acidic solution he used in his leaching studies might not fully represent soil conditions. However, the action of humic and small organic acids released from roots into natural soils accelerate the rate of potassium ion leaching, bringing it to a value approximated by the acid environment.

Ciceri reports data from three separate experiments, which ran for three hours, five hours and 15 hours. "The rate enhancement reported ... suggests the opportunity to reconsider stonemeal, particularly in those countries that cannot afford or cannot access traditional potassium fertilizers," the report says. Future studies may look at leaching of other elements from the feldspar, such as silicon and aluminum; longer time scales up to 1,000 hours; different flow rates; or different levels of acidity in the microfluidic solution. "The bigger data set you can build, the more confident you become in your results," Ciceri says.