MIT researchers and colleagues have won three of this year's prestigious R&D 100 Awards, which honor the 100 most technologically significant new products and processes.

The winners, who were chosen by the editors of R&D Magazine and a panel of more than 75 experts in a variety of disciplines, attended a black-tie banquet last week in Chicago.

Nine of this year's awards went to universities (often in collaboration with industry or a national laboratory); MIT won three of these.

The award-winning MIT inventions and the researchers involved are:

- A thermometer to measure temperatures inside high-temperature furnaces developed by Paul P. Woskov, principal research engineer at the Plasma Fusion Center; Charles H. Titus of T&R Associates; Daniel R. Cohn, acting assistant director of the PFC, and Jeffrey E. Surma of Pacific Northwest Laboratory of Weldon Machine Tool, Inc.

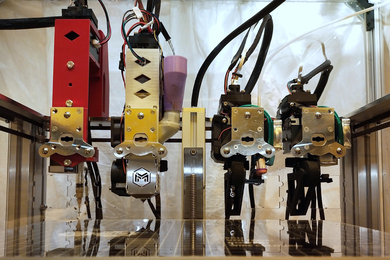

- A process and machine that create metal, ceramic and polymeric parts directly from a computer model by printing them in layers. Developers are Emanuel M. Sachs, associate professor of mechanical engineering; Michael J. Cima, associate professor of materials science and engineering, and Yehoram Uziel, president of Soligen, Inc.

- A device to reduce structural vibrations by an order of magnitude. Developers are Alexander H. Slocum, D'arbeloff Associate Professor of Mechanical Engineering and a consultant for Aesop, Inc.; Eric R. Marsh, a research assistant in mechanical engineering; James D. Flinchbaugh, president of Weldon Machine Tool, Inc.; Donald Bowers, President of LeBlond Makino Machine Tool Corp., and Doug Smith, a recent MIT alumnus now at Timken.

NEW THERMOMETER

When scientists at the Plasma Fusion Center began developing a furnace capable of melting solid hazardous wastes into a stable glass, they quickly found that existing technologies for measuring temperatures in furnaces were inadequate for their machine. Such readings are critical to optimizing and controlling the waste-remediation process, so the researchers invented a new thermometer that works well in the furnace and could have a number of other applications.

Essentially the device works by measuring the heat radiated from interior surfaces of the furnace. "When something gets hot, it emits radiation. We monitor that radiation, measure its strength, and from that determine the temperature," said Dr. Woskov.

While the bulk of the device-known as the active millimeter-wave pyrometer-is located outside the furnace, a small cylindrical tube extends into the furnace itself. The tube, which guides the millimeter waves used to make the measurements, can be rotated to determine the radiation coming from different areas of the furnace.

Among its advantages over other thermometers, the PFC device can record very high temperatures (up to 20,000' C) and can operate in a smoky environment.

The device is also capable of automatically determining emissivity, a parameter that is distinctive to a given surface and is key to determining the temperature of that surface. Other pyrometers require the user to manually enter the emissivity of a given surface as determined from a reference book. Usually that's not a problem. But in some processes the buildup of soot (as happens in the PFC furnace) or other materials on the surface continuously changes the emissivity. "In such situations you're kind of tripped up by conventional techniques," said Dr. Cohn.

The PFC pyrometer is the only device on the market that can automatically correct for changing emissivities. As a result, the researchers believe that it could be applied to other processes. For example, they wrote in their R&D 100 application that "in the manufacture of aluminum plate the temperature must be carefully controlled. [Yet] current pyrometers are unable to make a reliable measurement because of a surface oxide layer that changes emissivity in an unpredictable way." The active millimeter-wave pyrometer "could make possible a degree of [temperature] control [that is currently] not possible."

The pyrometer work is supported by the DOE Buried Waste Integrated Demonstration Program. See MIT Tech Talk 9/21/94 and 4/7/93 for more information on the overall waste-remediation program.

Longer descriptions of the other two MIT inventions to win 1994 R&D 100 awards will appear in a future issue of MIT Tech Talk.

A version of this article appeared in the September 28, 1994 issue of MIT Tech Talk (Volume 39, Number 6).