As the United States seeks to reinvigorate its job market and move past economic recession, MIT News examines manufacturing’s role in the country’s economic future through this series on work at the Institute around manufacturing.

Broadly speaking, the two major areas of research at MIT’s Microsystems Technology Laboratory (MTL) are electronics — transistors in particular — and microelectromechanical systems, or MEMS — tiny mechanical devices with moving parts. Both strains of research could have significant implications for manufacturing in the United States, but at least for the moment, the market for transistor innovation is far larger.

MTL’s Judy Hoyt is proof of the influence that academic research can have on that market. In the 1990s, she helped pioneer the use of “strained silicon” — silicon whose atoms have been pried apart slightly more than normal — to improve the performance of microchips. Intel, most of whose chips are produced in the United States, was the first chipmaker to introduce strained silicon, in 2003. But by now, Hoyt says, the technology has percolated throughout the industry.

Hoyt, a professor of electrical engineering at MIT, argues that U.S. chipmakers have a commercial incentive to keep manufacturing at home. Innovative ideas that afford a competitive advantage often emerge from the very process of building and operating a fabrication facility, Hoyt says. “In the course of doing the manufacturing, additional know-how gets generated,” she says. “If you do design here and do the actual fabrication and manufacturing elsewhere, it’ll work for a while, but in the long run, you can lose early access to the most advanced technologies.” Indeed, Intel — whose domination of the microprocessor market depends in large part on always being a few steps ahead of its competition technologically — recently began building a massive new production facility in Arizona.

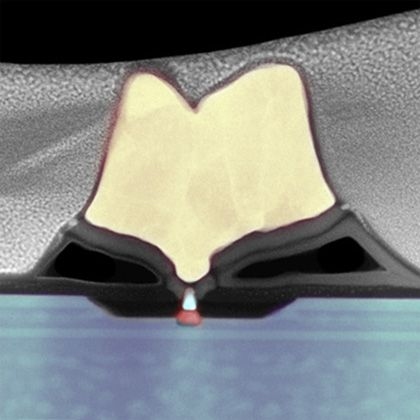

Hoyt continues to research chip technologies that are an even more radical departure from the norm than strained silicon was in the 1990s — and will thus require “additional know-how” to produce, she says. One approach is building transistors from strained nanowires of silicon or germanium. In particular, Hoyt says, her group is investigating techniques for fabricating the nanowires that would make mass production viable. She’s also collaborating with several other MTL researchers on what she describes as “new concepts about how a digital switch might operate” — concepts that, for example, involve quantum tunneling, a counterintuitive physical phenomenon in which a subatomic particle seems to magically pass through a physical barrier.

Compound interest

MTL’s Jesus del Alamo, on the other hand, researches ways to keep the existing transistor design going as long as possible. That design hasn’t changed much in the last 50 years, but chipmakers are finally bumping up against the fundamental physical limits of silicon. Del Alamo studies compound semiconductors — so called because they combine multiple elements, such as gallium, indium and arsenic — whose electrical properties offer advantages over silicon. If chipmakers can successfully introduce these exotic materials into their fabrication processes, they might be able to continue to improve chip performance without abandoning existing chip designs.

That’s a big “if,” however, as the chemicals and conditions required to create compound-semiconductor circuitry are incompatible with the processes currently used to produce silicon chips. The first chipmaker to reconcile the two could enjoy a pronounced competitive advantage.

“It was really Intel’s leadership about six, seven years ago that focused attention on the difficulties of traditional silicon scaling,” says del Alamo, the Donner Professor of Electrical Engineering at MIT. “For years, it was only Intel, ourselves and slowly, a small trickle of other universities that started looking at this. To the extent that U.S. industry in the form of, essentially, Intel is three, four years ahead of the rest of the world, then we might have an edge in this technology that might have implications for manufacturing.”

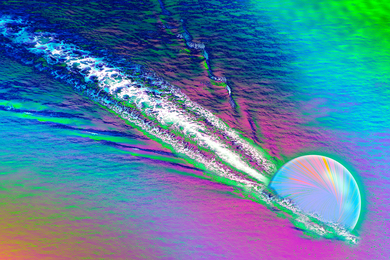

Today, compound semiconductors are used in high-speed electronics, such as the devices that process data in fiber-optic networks. But while compound-semiconductor transistors offer substantial performance gains over silicon transistors, they’re also substantially larger. For years, del Alamo’s group has been working to establish whether compound semiconductors’ advantages will persist even at the small scales required for digital-logic applications. Recently, del Alamo says, using MTL’s own fabrication facilities, his group has produced a compound-semiconductor chip with transistors whose critical dimensions are roughly the same as those of transistors found in commercial microprocessors. The transistors’ performance wasn’t up to the standard that commercial applications would demand, but, del Alamo says, “we think we know why, and we believe we can address the problems. So the technology looks very promising.”

Powering down

Sharing an office suite with del Alamo is Tomás Palacios, an MTL researcher best known for his work with graphene, a material that consists of a single layer of carbon atoms and has remarkable electronic and mechanical properties.

But Palacios’ group is also researching another compound semiconductor, gallium nitride, whose influence on manufacturing could extend well beyond the semiconductor industry. Gallium nitride is commonly used in light-emitting diodes, but Palacios is investigating its application in power electronics — the devices in both the electrical grid and household electronics that change the voltage of electrical power or switch back and forth between alternating and direct current.

“Intrinsically, in the U.S., we are going to have higher wages than in many other places in the world, so if we want to compete with those places, we need to be more efficient,” says Palacios, the Emanuel E. Landsman (1958) Career Development Associate Professor of Electronics at MIT. Approximately 30 percent of the electricity produced in the United States, Palacios explains, goes to manufacturing.

“Most of that electricity is used in powering motors and engines of different kinds,” he says. “Those motors are actually very inefficient. They are being controlled by old power electronics.” Gallium nitride power electronics, Palacios says, could cut the electricity consumed by U.S. manufacturing by more than 30 percent. “For a given voltage, gallium nitride has three orders of magnitude less resistance than conventional silicon-based electronics, so it’s much more efficient,” Palacios says.

The problem is that gallium nitride is such a good conductor that transistors made from it are hard to shut off. Palacios’ group has developed — and filed a couple of patents on — a new transistor design that should address that problem. They continue to refine the design, in the hopes of making gallium nitride power electronics both more efficient and easier to mass produce.

Broadly speaking, the two major areas of research at MIT’s Microsystems Technology Laboratory (MTL) are electronics — transistors in particular — and microelectromechanical systems, or MEMS — tiny mechanical devices with moving parts. Both strains of research could have significant implications for manufacturing in the United States, but at least for the moment, the market for transistor innovation is far larger.

MTL’s Judy Hoyt is proof of the influence that academic research can have on that market. In the 1990s, she helped pioneer the use of “strained silicon” — silicon whose atoms have been pried apart slightly more than normal — to improve the performance of microchips. Intel, most of whose chips are produced in the United States, was the first chipmaker to introduce strained silicon, in 2003. But by now, Hoyt says, the technology has percolated throughout the industry.

Hoyt, a professor of electrical engineering at MIT, argues that U.S. chipmakers have a commercial incentive to keep manufacturing at home. Innovative ideas that afford a competitive advantage often emerge from the very process of building and operating a fabrication facility, Hoyt says. “In the course of doing the manufacturing, additional know-how gets generated,” she says. “If you do design here and do the actual fabrication and manufacturing elsewhere, it’ll work for a while, but in the long run, you can lose early access to the most advanced technologies.” Indeed, Intel — whose domination of the microprocessor market depends in large part on always being a few steps ahead of its competition technologically — recently began building a massive new production facility in Arizona.

Hoyt continues to research chip technologies that are an even more radical departure from the norm than strained silicon was in the 1990s — and will thus require “additional know-how” to produce, she says. One approach is building transistors from strained nanowires of silicon or germanium. In particular, Hoyt says, her group is investigating techniques for fabricating the nanowires that would make mass production viable. She’s also collaborating with several other MTL researchers on what she describes as “new concepts about how a digital switch might operate” — concepts that, for example, involve quantum tunneling, a counterintuitive physical phenomenon in which a subatomic particle seems to magically pass through a physical barrier.

Compound interest

MTL’s Jesus del Alamo, on the other hand, researches ways to keep the existing transistor design going as long as possible. That design hasn’t changed much in the last 50 years, but chipmakers are finally bumping up against the fundamental physical limits of silicon. Del Alamo studies compound semiconductors — so called because they combine multiple elements, such as gallium, indium and arsenic — whose electrical properties offer advantages over silicon. If chipmakers can successfully introduce these exotic materials into their fabrication processes, they might be able to continue to improve chip performance without abandoning existing chip designs.

That’s a big “if,” however, as the chemicals and conditions required to create compound-semiconductor circuitry are incompatible with the processes currently used to produce silicon chips. The first chipmaker to reconcile the two could enjoy a pronounced competitive advantage.

“It was really Intel’s leadership about six, seven years ago that focused attention on the difficulties of traditional silicon scaling,” says del Alamo, the Donner Professor of Electrical Engineering at MIT. “For years, it was only Intel, ourselves and slowly, a small trickle of other universities that started looking at this. To the extent that U.S. industry in the form of, essentially, Intel is three, four years ahead of the rest of the world, then we might have an edge in this technology that might have implications for manufacturing.”

Today, compound semiconductors are used in high-speed electronics, such as the devices that process data in fiber-optic networks. But while compound-semiconductor transistors offer substantial performance gains over silicon transistors, they’re also substantially larger. For years, del Alamo’s group has been working to establish whether compound semiconductors’ advantages will persist even at the small scales required for digital-logic applications. Recently, del Alamo says, using MTL’s own fabrication facilities, his group has produced a compound-semiconductor chip with transistors whose critical dimensions are roughly the same as those of transistors found in commercial microprocessors. The transistors’ performance wasn’t up to the standard that commercial applications would demand, but, del Alamo says, “we think we know why, and we believe we can address the problems. So the technology looks very promising.”

Powering down

Sharing an office suite with del Alamo is Tomás Palacios, an MTL researcher best known for his work with graphene, a material that consists of a single layer of carbon atoms and has remarkable electronic and mechanical properties.

But Palacios’ group is also researching another compound semiconductor, gallium nitride, whose influence on manufacturing could extend well beyond the semiconductor industry. Gallium nitride is commonly used in light-emitting diodes, but Palacios is investigating its application in power electronics — the devices in both the electrical grid and household electronics that change the voltage of electrical power or switch back and forth between alternating and direct current.

“Intrinsically, in the U.S., we are going to have higher wages than in many other places in the world, so if we want to compete with those places, we need to be more efficient,” says Palacios, the Emanuel E. Landsman (1958) Career Development Associate Professor of Electronics at MIT. Approximately 30 percent of the electricity produced in the United States, Palacios explains, goes to manufacturing.

“Most of that electricity is used in powering motors and engines of different kinds,” he says. “Those motors are actually very inefficient. They are being controlled by old power electronics.” Gallium nitride power electronics, Palacios says, could cut the electricity consumed by U.S. manufacturing by more than 30 percent. “For a given voltage, gallium nitride has three orders of magnitude less resistance than conventional silicon-based electronics, so it’s much more efficient,” Palacios says.

The problem is that gallium nitride is such a good conductor that transistors made from it are hard to shut off. Palacios’ group has developed — and filed a couple of patents on — a new transistor design that should address that problem. They continue to refine the design, in the hopes of making gallium nitride power electronics both more efficient and easier to mass produce.