A recent award from the U.S. Defense Advanced Research Projects Agency (DARPA) brings together researchers from Massachusetts Institute of Technology (MIT), Carnegie Mellon University (CMU), and Lehigh University (Lehigh) under the Multiobjective Engineering and Testing of Alloy Structures (METALS) program. The team will research novel design tools for the simultaneous optimization of shape and compositional gradients in multi-material structures that complement new high-throughput materials testing techniques, with particular attention paid to the bladed disk (blisk) geometry commonly found in turbomachinery (including jet and rocket engines) as an exemplary challenge problem.

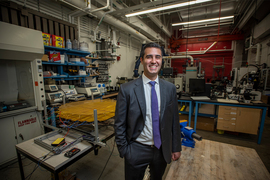

“This project could have important implications across a wide range of aerospace technologies. Insights from this work may enable more reliable, reusable, rocket engines that will power the next generation of heavy-lift launch vehicles,” says Zachary Cordero, the Esther and Harold E. Edgerton Associate Professor in the MIT Department of Aeronautics and Astronautics (AeroAstro) and the project’s lead principal investigator. “This project merges classical mechanics analyses with cutting-edge generative AI design technologies to unlock the plastic reserve of compositionally graded alloys allowing safe operation in previously inaccessible conditions.”

Different locations in blisks require different thermomechanical properties and performance, such as resistance to creep, low cycle fatigue, high strength, etc. Large scale production also necessitates consideration of cost and sustainability metrics such as sourcing and recycling of alloys in the design.

“Currently, with standard manufacturing and design procedures, one must come up with a single magical material, composition, and processing parameters to meet ‘one part-one material’ constraints,” says Cordero. “Desired properties are also often mutually exclusive prompting inefficient design tradeoffs and compromises.”

Although a one-material approach may be optimal for a singular location in a component, it may leave other locations exposed to failure or may require a critical material to be carried throughout an entire part when it may only be needed in a specific location. With the rapid advancement of additive manufacturing processes that are enabling voxel-based composition and property control, the team sees unique opportunities for leap-ahead performance in structural components are now possible.

Cordero’s collaborators include Zoltan Spakovszky, the T. Wilson (1953) Professor in Aeronautics in AeroAstro; A. John Hart, the Class of 1922 Professor and head of the Department of Mechanical Engineering; Faez Ahmed, ABS Career Development Assistant Professor of mechanical engineering at MIT; S. Mohadeseh Taheri-Mousavi, assistant professor of materials science and engineering at CMU; and Natasha Vermaak, associate professor of mechanical engineering and mechanics at Lehigh.

The team’s expertise spans hybrid integrated computational material engineering and machine-learning-based material and process design, precision instrumentation, metrology, topology optimization, deep generative modeling, additive manufacturing, materials characterization, thermostructural analysis, and turbomachinery.

“It is especially rewarding to work with the graduate students and postdoctoral researchers collaborating on the METALS project, spanning from developing new computational approaches to building test rigs operating under extreme conditions,” says Hart. “It is a truly unique opportunity to build breakthrough capabilities that could underlie propulsion systems of the future, leveraging digital design and manufacturing technologies.”

This research is funded by DARPA under contract HR00112420303. The views, opinions, and/or findings expressed are those of the author and should not be interpreted as representing the official views or policies of the Department of Defense or the U.S. government and no official endorsement should be inferred.