Last November, MIT announced the launch of its Hong Kong Innovation Node, a collaborative space that aims to connect the MIT community with resources — including advanced manufacturing capabilities — and other opportunities in Hong Kong and the neighboring Pearl River Delta. Since then, the Innovation Node has convened MIT students, faculty, and researchers to work on entrepreneurial and research projects alongside Hong Kong-based students and faculty, MIT alumni, entrepreneurs, and businesses. By combining resources and talent, the Innovation Node — in partnership with the MIT Innovation Initiative — aims to help students learn how to move ideas more rapidly from lab to market.

Charles Sodini, the Clarence J. LeBel Professor in Electrical Engineering and faculty director of the node, spoke with MIT News about the Innovation Node’s activities since its launch.

Q. What has the Hong Kong Innovation Node accomplished to date?

A. The Innovation Node formally launched in June with MIT Kickstart, a technology-based entrepreneurship program involving 12 MIT students and 12 students from universities across Hong Kong. The immersive program challenged students to bring their ideas to impact by forming international teams, building rapid prototypes, and pitching their projects.

Students participated in workshops led by industry experts, were coached by alumni mentors, and visited local startups and manufacturing facilities in Shenzhen, near Hong Kong in the Pearl River Delta. The program culminated in a final session where students presented their work and demonstrated their prototypes. This showcase was attended by over 100 people, including MIT alumni, senior government and academic officials, entrepreneurs, and industry leaders.

We’ve also made two great hires for the Innovation Node: Brian Yen as executive director, and Marina Chan as strategic development manager. In Brian, we have a veteran of startups in technologies including video games, electronic medical records, and scientific instruments. Since moving to Hong Kong in 2005, he has been a consultant to U.S. technology firms looking to invest or partner in China, as well as investors requiring in-depth analysis of Chinese tech firms. Marina began her career in the investment banking industry, before earning her master’s degree in education from Harvard University. Her passion for education led her to found Alpha Commons, an educational program that cultivates creativity in children through engagement with technology.

Q. What’s been the response of those who have worked with or participated in the Innovation Node?

A. Student feedback from MIT Kickstart has been genuinely positive. A common theme is that the experience has been uniquely eye-opening: Participants learned about the complexity of large-scale manufacturing processes firsthand, driving home just how much it takes to bring a product from design to production — as well as the cultural nuances of doing business in China. Students reported a new appreciation for how advanced the technology has become, and for China’s position as a global player. Many came away with a better grasp that the potential of manufacturing in this region is huge, but requires understanding of the marketplace and what is important to the local consumer to be successful. The experience opened their eyes to the possibilities and value of international collaboration.

When collaborating with international peers, one participant mentioned how he was “blown away by people’s ambition, creativity, drive, passion and intelligence.” This is testimony to the enormous talent in both regions and the importance of creating such opportunities to bridge connections. Students who came through our program have continued to stay in touch with the node and with each other.

Beyond the program, the node has facilitated support for students via introductions to industry mentors, incubation programs, and Chinese companies specializing in low-volume manufacturing and prototyping. We found that students value these connections as they begin to seriously consider bringing their ideas to the next level. We want to be a key source of support for them as they navigate the Chinese hardware system startup ecosystem.

Q. What is the Innovation Node working on now? What are its next steps?

A. The node will launch its second program, the MIT Entrepreneurship and Maker Skills Integrator (MEMSI), in January. This two-week, fully immersive mini-accelerator for aspiring innovators will connect MIT students with their peers from universities in Hong Kong.

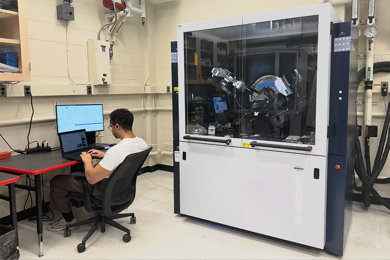

MEMSI is designed for students who want to build skills in entrepreneurship, hardware production, and product development for connected devices. Teams will work together to choose a customer problem to solve, understand customers’ needs, develop a solution, and build a prototype using advanced techniques; build skills that will help them build successful businesses later in life; and see mass production in real time during factory tours in Shenzhen, China. At the end of the two-week program, participants will present their business ideas and prototypes to a panel of entrepreneurs, investors, and industry leaders.

Finally, we’re searching for a permament home for the Innovation Node in Hong Kong, to create an engaging physical space for collaboration, connection, and making. We’re seeking an open working environment equipped with technology comparable to the maker equipment at MIT, and connected digitally to the MIT campus.