In work that could radically change how engineers search for new materials, MIT researchers have developed a way to test the mechanical properties of almost 600 different materials in a matter of days -- a task that would have taken weeks using conventional techniques.

The new process could lead to the faster identification of dental implants that don't crack, tank armor that's more resistant to missiles, and other materials dependent on mechanical properties like stiffness and toughness.

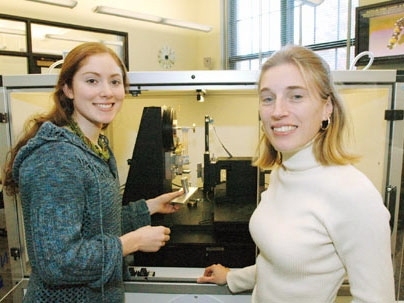

The trick? The team, led by Assistant Professor Krystyn J. Van Vliet of the Department of Materials Science and Engineering, miniaturized the process.

Van Vliet, MSE graduate student Catherine A. Tweedie, research associate Daniel G. Anderson of the Department of Chemical Engineering and Institute Professor Robert Langer describe the work in the cover story of the November issue of Advanced Materials.

In 2004 Anderson, Langer and a colleague reported using robotic technology to deposit more than 1,700 spots of biomaterial (roughly 500 different materials in triplicate) on a glass slide measuring only 25 millimeters wide by 75 millimeters long. Twenty such slides, or microarrays, could be made in a single day.

The arrays were then used to determine which materials were most conducive to the growth and differentiation of human embryonic stem cells. (See MIT technology jump-starts human embryonic stem cell work.)

Enter Van Vliet, whose lab studies how the mechanical properties of a surface affect cells growing on that surface. Curious as to whether the Langer team had probed the mechanical properties of the biomaterials, she contacted Langer, who introduced her to Anderson.

And what began as an isolated question turned into a collaboration with wider implications.

Together the researchers showed that the mechanical properties of each biomaterial could indeed be determined -- and quickly -- by combining the arrays with nanoindentation, a technique key to Van Vliet's work.

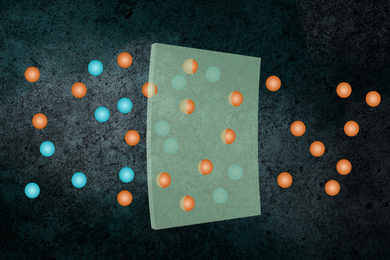

In nanoindentation a hard, small probe is pressed into a more compliant material, to depths many times smaller than the diameter of a human hair. By measuring the force applied and how deeply the probe penetrates the material, scientists can learn a great deal about the material's mechanical properties.

"The spots of material Dan was making had diameters about three times that of a human hair, a scale perfect for nanoindenation," Van Vliet said. So the team created new arrays of roughly 600 unique polymers. "Each dot was a combination of two different monomers, or building blocks, so we could map out the effects of the percentage of each monomer on the properties of the material," Van Vliet said. And in 24 hours Tweedie, using the nanoindenter, had that data in hand.

It would have taken many weeks to analyze that many materials using traditional techniques, which involve "the serial process of bulk-material synthesis, batch-sample preparation, and individual-sample testing," the team writes in Advanced Materials. Further, Anderson explained, many materials have been discovered when a scientist thinks about what the perfect properties of a material should be, and then invents it. "But that can take lots of time," he said.

Enter combinatorial libraries. "Instead of trying to engineer perfect materials, let's make thousands at the smallest scale we can, and see if we can find some materials with unexpected or interesting properties," Anderson said.

Tweedie notes that even in this first "proof of principle" experiment there were some surprises. For example, she said, "the stiffness of certain polymers depended more on the combination of monomers used (how much of A and B) rather than the structure of each monomer, with certain combinations resulting in very compliant polymers. These were very large, unanticipated changes in mechanical properties that could then be optimized further in a subset of combinations."

Describing the collaboration that brought about these results, Van Vliet concluded: "It's really made both [of our groups] think in different ways about what we're doing."

This work was funded by the National Institutes of Health, the U.S. Army Research Office through MIT's Institute for Soldier Nanotechnologies, and the National Defense Science and Engineering Graduate Fellowship program.

A version of this article appeared in MIT Tech Talk on November 30, 2005 (download PDF).