MIT's latest patented invention, a kitchen appliance that automatically dispenses dry ingredients for baking, can be credited in part to a taste for great cookies.

It all began with a class called Designing Smart Machines in which students were asked to come up with ideas for novel machines that would incorporate a microprocessor. With a handful of the best ideas, they divided themselves into groups to determine the potential market for each machine and to build prototypes.

"My dad makes great cookies," said graduate student Amy Smith of the Department of Mechanical Engineering, recalling the genesis of the appliance invention. "And I thought, `wouldn't it be great to have a machine where you could push a button and his cookies came out?'"

Ms. Smith's idea interested Louise Jandura and Susan Rynerson, also graduate students in mechanical engineering, and in about eight weeks-the length of the class-the three produced a working prototype of the machine. (Given the time constraints of the class they ruled out a full-fledged cookie maker, opting instead for a device to dispense dry ingredients.)

Dubbed the Smart Cannister, the machine was so novel that the students' instructor, Professor Will Durfee (now at the University of Minnesota), suggested it might be patentable. "He thought it had a legitimate chance of becoming a real product," said Ms. Jandura.

That was almost three years ago. This month the three received a patent for their invention.

HOW DOES IT WORK?

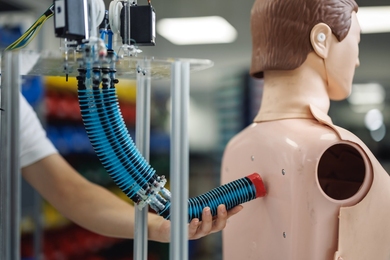

The prototype Smart Cannister automatically dispenses sugar and flour into a bowl placed inside the unit (sugar and flour were chosen as test ingredients because their properties are representative of the range of dry ingredients that the machine could be modified to include). Using a control panel "that doesn't require a manual," Ms. Jandura said, users can select either a specific amount of one ingredient or a pre-programmed recipe. Final step: press the "dispense" button.

This user interface, however, is deceptively simple. It hides a unique set of components, many of which the inventors designed and built from scratch. For example, diagonal slats or baffles in the cannisters that hold the ingredients are key to the efficient dispersal of the ingredients. Other custom-made components include the scale that weighs the ingredients and the software underlying the overall system.

Although there are other patented machines for dispensing ingredients, the Smart Cannister is the most flexible. For example, the machines developed for industrial applications dispense repetitive batches rather than variable amounts. They also cost much more to produce and are not user-friendly. The only other dispensing product for the home market cannot dispense more than one ingredient.

THE PATENT PROCESS

Since completing Professor Durfee's course, Ms. Smith, Ms. Jandura and Ms. Rynerson (who has since graduated) have had the equivalent of a second class-this time in US patent law. Working with Alex Laats, a licensing officer at the Technology Licensing Office and a patent attorney, they filed a formal patent application and revised that document when it was initially turned down. During this process the students "answered technical questions and did a lot of review work on related patents," Ms. Jandura said.

All along Mr. Laats has also been working to license the Smart Cannister technology to a company that could turn it into an actual product (for more information, contact him at

"It was a good project to work on, but it's not our lives' work," said Ms. Smith, who expects to receive the Engineer's degree in mechanical engineering this June. Her thesis work involved developing a grain mill for third world countries (she did the design and field testing of this mill in Tambacounda, Senegal). Ms. Jandura is currently working toward a PhD in mechanical engineering. Her research involves understanding the human sense of touch.

Nevertheless, both students view the Smart Cannister as an important accomplishment. Said Ms. Smith: "I had absolutely no experience with microprocessors before [that class]. So when I look at all the wiring, programming, etc., we did, I think, `Wow. It's pretty cool we did that.'"

A version of this article appeared in MIT Tech Talk on April 26, 1995.