Shape-memory polymers are not a new discovery, as anyone who has played with Shrinky-Dinks or who has used heat-shrink tubing for wires in an electronic circuit can testify. But now, thanks to new analysis by researchers at MIT, the behavior of these interesting materials has been mathematically modeled in detail, which should make it easier to use the materials in new ways; potential applications include implantable biomedical devices and space structures that could be launched in a compact form and then unfurled once in orbit.

Shape-memory materials share an unusual property: They can be squished, twisted or bent into a variety of configurations, but when heated above some threshold temperature (for example, by being dunked in warm water or heated in an oven) they revert to the original shape in which they were made. Metal alloys such as nitinol (an alloy of nickel and titanium) were the first such materials studied, but polymer-based shape-memory materials have some significant advantages over the metal ones, says Lallit Anand, the Warren and Towneley Rohsenow Professor of Mechanical Engineering at MIT.

Anand and graduate students Vikas Srivastava PhD ’10 and Shawn Chester studied a representative shape-memory polymer material that can double in size; in contrast, nitinol can only increase in size by about 5 percent. This added capacity could allow the design of more complex geometries for applications, Srivastava says. In addition, the material itself is softer and has a rubbery consistency, and may be less likely to damage surrounding tissues when used in biomedical devices.

While shape-shifting polymers have been known for a few decades, until now there has been no detailed understanding of the basic molecular behavior responsible for the materials’ properties, and so trying to adapt them to any new application was essentially “all just trial and error,” Anand says. A numerical understanding of their behavior didn’t matter for applications such as heat-shrink tubing, but increasingly these materials are being harnessed for critical applications in biomedical devices, data-storage systems or self-deployable space structures that require great precision.

Srivastava says he believes that the numerical simulation he and his fellow researchers developed “will allow relatively accurate design of complex shape-memory polymer-based devices and systems,” and thus will bring such applications closer to becoming practical.

Some of the earliest work on designing biomedical devices using such materials was carried out by MIT Institute Professor Robert Langer but that work was done without the ability to model the material’s behavior accurately on a computer.

Now, Anand says he and his students have developed the theory and numerical simulation capability necessary to design various devices, by predicting their strains, forces and interactions. Moreover, he says, the simulations have been confirmed in laboratory tests. This should make it easier to optimize the designs of new applications.

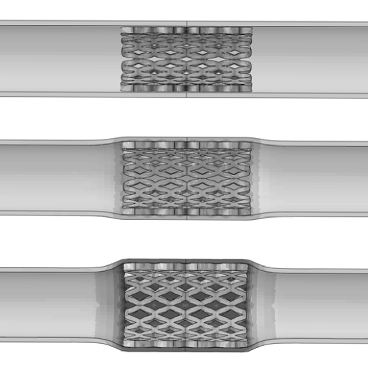

One detailed simulation the team carried out was a design for a polymer-based stent, a device for keeping a blood vessel open. Their analysis and experimental verification were described in a paper published in August in the Journal of the Mechanics and Physics of Solids. Srivastava was the lead author, with Chester and Anand as co-authors. The work was supported by the National Science Foundation and the MIT-Singapore Alliance.

Ken Gall, a professor of materials science at Georgia Institute of Technology, who was not involved in this research, says, “This is no doubt the most comprehensive analysis published on the behavior of shape memory polymers.” He adds that it “will provide a means to assess proposed applications of the materials, and also motivate new applications.”

Although this work represents “a step on the path” to more widespread use of these materials, Anand says there remain some unanswered questions, such as the long-term durability of such structures when subjected to millions of cycles of deformation. Also, the analysis was focused on one specific composition out of a whole family of shape-memory polymers. Though the underlying materials-science characteristics should be similar and the formulas they developed are “reasonably general,” further studies will be needed to pin down any possible differences. “The work will continue,” he says.

Video shows an example of the shape-memory polymer going through a transformation from a stretched shape back to its original form, by being placed in warm water.

Video courtesy of Vikas Srivastava and Shawn Chester

Shape-memory materials share an unusual property: They can be squished, twisted or bent into a variety of configurations, but when heated above some threshold temperature (for example, by being dunked in warm water or heated in an oven) they revert to the original shape in which they were made. Metal alloys such as nitinol (an alloy of nickel and titanium) were the first such materials studied, but polymer-based shape-memory materials have some significant advantages over the metal ones, says Lallit Anand, the Warren and Towneley Rohsenow Professor of Mechanical Engineering at MIT.

Anand and graduate students Vikas Srivastava PhD ’10 and Shawn Chester studied a representative shape-memory polymer material that can double in size; in contrast, nitinol can only increase in size by about 5 percent. This added capacity could allow the design of more complex geometries for applications, Srivastava says. In addition, the material itself is softer and has a rubbery consistency, and may be less likely to damage surrounding tissues when used in biomedical devices.

While shape-shifting polymers have been known for a few decades, until now there has been no detailed understanding of the basic molecular behavior responsible for the materials’ properties, and so trying to adapt them to any new application was essentially “all just trial and error,” Anand says. A numerical understanding of their behavior didn’t matter for applications such as heat-shrink tubing, but increasingly these materials are being harnessed for critical applications in biomedical devices, data-storage systems or self-deployable space structures that require great precision.

Srivastava says he believes that the numerical simulation he and his fellow researchers developed “will allow relatively accurate design of complex shape-memory polymer-based devices and systems,” and thus will bring such applications closer to becoming practical.

Some of the earliest work on designing biomedical devices using such materials was carried out by MIT Institute Professor Robert Langer but that work was done without the ability to model the material’s behavior accurately on a computer.

Now, Anand says he and his students have developed the theory and numerical simulation capability necessary to design various devices, by predicting their strains, forces and interactions. Moreover, he says, the simulations have been confirmed in laboratory tests. This should make it easier to optimize the designs of new applications.

One detailed simulation the team carried out was a design for a polymer-based stent, a device for keeping a blood vessel open. Their analysis and experimental verification were described in a paper published in August in the Journal of the Mechanics and Physics of Solids. Srivastava was the lead author, with Chester and Anand as co-authors. The work was supported by the National Science Foundation and the MIT-Singapore Alliance.

Ken Gall, a professor of materials science at Georgia Institute of Technology, who was not involved in this research, says, “This is no doubt the most comprehensive analysis published on the behavior of shape memory polymers.” He adds that it “will provide a means to assess proposed applications of the materials, and also motivate new applications.”

Although this work represents “a step on the path” to more widespread use of these materials, Anand says there remain some unanswered questions, such as the long-term durability of such structures when subjected to millions of cycles of deformation. Also, the analysis was focused on one specific composition out of a whole family of shape-memory polymers. Though the underlying materials-science characteristics should be similar and the formulas they developed are “reasonably general,” further studies will be needed to pin down any possible differences. “The work will continue,” he says.

Video shows an example of the shape-memory polymer going through a transformation from a stretched shape back to its original form, by being placed in warm water.

Video courtesy of Vikas Srivastava and Shawn Chester