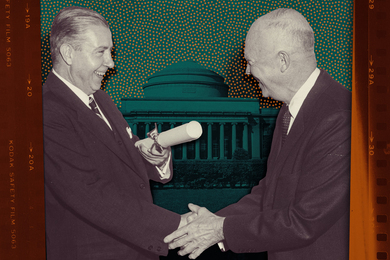

Doctoral candidate Saul Griffith, whose inventions include a "desktop printer" for low-cost eyeglass lenses, received the $30,000 Lemelson-MIT Student Prize for inventiveness during a ceremony Feb. 19 at MIT's Stratton Student Center.

Professor Merton Flemings, director of the Lemelson-MIT Program, cited Griffith's commitment to improving the world through invention and his creative way of inspiring children to learn science and engineering as important reasons for choosing him.

"Saul tackles some very challenging real-world problems, yet at the same time there is a wonderful sense of playfulness and simplicity to his work," Flemings said. "In particular, his low-cost vision-testing and lens-manufacturing inventions could dramatically improve life for billions of people in developing countries who cannot access nor afford prescription glasses."

"It's sometimes easier for engineers and scientists to work on the next bio drug or the next PDA, but there are some beautiful problems that a lot of people don't go after because it's hard to get support and funding and it's incredibly hard to be successful," Griffith said. "It would be nice if my work inspired others to address some of these problems and make them more acceptable."

Much of Griffith's research is in industrial materials science and manufacturing. "I'm influenced by the elegant way nature manufactures things, which is significantly better than the way humans do. I hope to develop new manufacturing processes that are simple, and can make things efficiently and with less waste. You can characterize my work as 'tools of mass construction,'" he said.

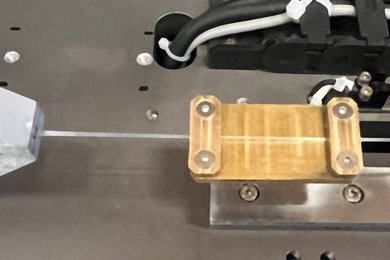

Griffith's advances in low-cost lenses sprang from his interests in rapid prototyping technologies and efficient manufacturing. Using a process called programmable molding, he created a portable device similar to a desktop printer that can produce any prescription lens from a single mold surface in five to 10 minutes. The device casts the lenses by applying pressure and constraints to a programmable membrane which becomes the mold surface under pressure. Griffith currently uses car window tinting film for the membrane and a reservoir of baby oil for applying the correct pressure. A large range of lens types, covering the majority of prescriptions, can be cast from two such mold surfaces.

Traditional lens manufacturing systems require expensive molds for each lens type. In remote rural areas, it is cost-prohibitive to maintain a library of thousands of lenses for relatively small populations of people. The traditional process not only comes with enormous inventory and handling costs, but also can result in excessive waste. Griffith's patent-pending device essentially eliminates these problems.

Efficient lens manufacturing is only half the issue, however. Proper diagnosis of vision problems is the other half. Current automatic diagnostic technologies are expensive, fragile and error-prone. Because they rely on a patient looking at electronically generated images a few inches away from his or her face, they can lead to incorrect diagnoses. Highly skilled people also are required to operate these machines.

To resolve this problem, Griffith has prototyped a device to test the human eye. Patients need only wear the device, which looks like an oversized pair of goggles, and look at the world around them. An electronic sensor superimposed on the goggles monitors the lens in the wearer's eye and adjusts the device's lens to cancel the refractive errors, thus determining the correct prescription.

In 2001, Griffith and colleague Neil Houghton won the Harvard Business School Social Enterprise Business Plan Contest for the concept. They have since started a company called Low Cost Eyeglasses (http://www.lowcosteyeglasses.net) to manufacture and market the product.

Griffith attributes his inventiveness to his nurturing parents, an artist and an engineer who reside in his hometown of Sydney, Australia. "I was always tinkering with things I found lying around, just to get ideas," he recalled. "When you're a kid you don't really think about it, but it gives you quite a large library of knowledge about how stuff works. Now, I can subconsciously draw upon all the things I broke growing up. Fortunately, my parents encouraged my toy de-construction!"

Through a project called Howtoons (http://www.howtoons.org), Griffith and collaborators Joost Bonsen and Nick Dragotta seek to instill that same mischievous spirit of discovery in future generations of kids. Part comic strip and part science experiment, the one-page Howtoons help children find imaginative new uses for soda bottles, plastic buckets, duct tape, balloons, ice, salt and other household materials. Griffith said the project aims to inspire kids to see the world not for what it is, but for what it could be.

Griffith's doctoral thesis at the Media Laboratory explores the relationship between information and physical structure in materials and self-assembly. His research is sponsored by the National Science Foundation Center for Bits and Atoms and DARPA.

The $30,000 Lemelson-MIT Student Prize is awarded annually to an MIT senior or graduate student who has created or improved a product or process, applied a technology in a new way, redesigned a system or in other ways has demonstrated remarkable inventiveness. More information on the Lemelson-MIT Program is online at http://web.mit.edu/invent.

A version of this article appeared in MIT Tech Talk on February 25, 2004.