The 80,000-plus kinds of proteins in our body, when in fragments called peptides, transform themselves like tiny smart Legos into millions of essential substances.

MIT's Shuguang Zhang and other scientists have recently discovered that these same peptides can be tweaked into forming completely new natural materials that may be able to perform a variety of useful functions inside and outside the body.

"The emerging perception is that self-assembling peptides form a new class of materials set to become commercially viable," said Dr. Zhang, a principal research scientist and associate director of the Center for Biomedical Engineering. Dr. Zhang, who accidentally discovered one type of self-assembling peptide himself, convened a first-of-its-kind workshop in Crete this summer to bring together scientists and engineers who are working on different aspects of the peptides' self-assemblies.

At the July workshop, more than 80 researchers from around the world met with sponsors of public and private funding agencies to discuss the future of self-assembling peptides in biology, medicine, materials science and engineering. This "very successful workshop... seemed to produce new insights from a creative blending of different disciplinary perspectives," Norman Metzger of the National Academy of Sciences later said about the event.

Participants walked away with a spirit of excitement about the future, Dr. Zhang said. He and his colleagues already are planning a second meeting for summer 2001.

FORCES OF GOOD AND EVIL

Like Dr. Jekyll and Mr. Hyde, the same peptides can do good or cause harm. On one hand is their useful ability to form extremely flexible, strong substances like silk. The flip side is their ability to form harmful substances such as the nonsoluble proteins that attack cells in the brain and cause Alzheimer's and other neurological diseases.

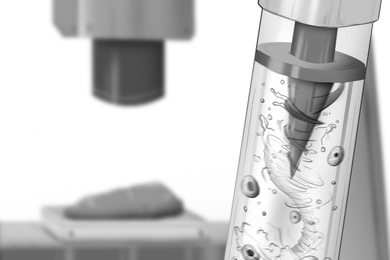

Researchers have found that peptides can self-assemble into non-protein-like structures such as fibers, tubules, sheets and thin layers. They can be made responsive to changes in acidity, mechanical forces, temperature, pressure, electrical and magnetic fields and light. They are stable at temperatures up to 350���C and can be produced up to a ton at a time at affordable cost. They can be programmed to biodegrade.

Self-assembling peptides are being developed for uses in tissue engineering (the biodegradable ones are a perfect scaffold for growing human tissue), biomedical devices, industrial fluids and personal care products.

In short, self-assembling peptides may be "the ideal biological material," Dr. Zhang said. "They've been called the wonder polymers of the 21st century."

A NATURAL PHENOMENON

On one level, it seems odd that tiny mindless bits of protein can pull themselves together in very specific ways. But Dr. Zhang points out that "self-assembly" is ubiquitous in nature. Some examples are schools of fish or flocks of birds. No individual is in charge of the master plan, yet they all fall into place because they are programmed to do so.

Each protein has a characteristic three-dimensional structure that has to chemically and structurally lock into place with another protein like tiny Legos. When they do this, they form extremely stable and ordered structures.

Several distinctive types of peptides have been developed:

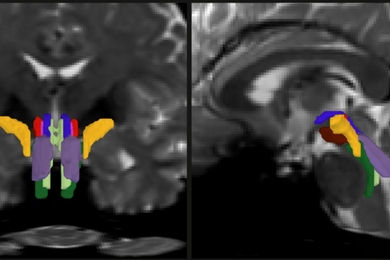

- Type I peptides undergo intermolecular self-assembly to form a gel matrix that can be used as a scaffold for tissue engineering.

- Type II peptides undergo structural transformations for intermolecular and intramolecular self-assembly. When a cell loses control, its proteins can self-assemble into more complex structures outside the cell itself, such as the amyloid fibers and plaques associated with certain infectious protein conformational disorders such as "mad cow disease" and age-related diseases such as Alzheimer's. Analysis of the molecular switch that allows this to occur will provide insight into the onset of these diseases.

- Type III peptides undergo self-assembly onto surfaces to form a sort of molecular "hook and Velcro" that interacts with other molecules and control cell patterns.

- Type IV peptides undergo assembly with nucleic acids to promote gene delivery.

"These systems represent a significant advance in the molecular engineering of protein fragments for diverse technological innovations," Dr. Zhang said.

A SERENDIPITOUS DISCOVERY

Six years ago, Dr. Zhang was working in the laboratory of Alexander Rich, the William Thompson Sedgwick Professor of Biophysics in the Department of Biology, exposing rat cells to the same kind of substance that builds up in the brains of Alzheimer's patients. He half-expected to see the cells, left overnight in oligopeptides, to be dead in the morning. Instead, one out of six dishes of cells were thriving and had grown right on top of a membrane.

It took Dr. Zhang a year to figure out the molecular reasons that these peptides undergo self-assembly in the presence of a salt. The answer came to him one day as he was playing with his son's Legos and saw how precisely the pieces fit together. It was the first self-complementary oligopeptide found in nature, Dr. Zhang said. He recognized it as a new material with many potential applications. MIT filed for a patent, which was issued in 1997.

As he further manipulated the oligopeptides, he found that he could use them as a substrate and grow cells on them in any conceivable pattern. He made them into striking rows and lines and bars. He even spelled out the letters "MIT" using cells.

Dr. Zhang's work on these Type III peptides may lead to advances in biological surface engineering, permitting new types of experiments to probe the details of cell physiology by making them easier to study than the jumbled mass that usually grows in a petri dish.

He also is working with these Type III peptides to create a new type of cell chip, which, like the gene chip used to diagnose diseases and sequence genes, could be used to screen drugs for effectiveness. This was included in a paper in the journal Biomaterials in June.

"This is a truly multidisciplinary approach to conducting research and producing novel materials," Dr. Zhang said. "We learn from nature and go one step further to create new materials. As Francis Crick best put it, 'In nature, hybrid species are usually sterile, but in science the reverse is often true. Hybrid subjects are often astonishingly fertile, whereas if a scientific discipline remains too pure, it usually wilts.'"

Over the years, he and his present and former students--Michale Altman, Rodney Chan, Eric Chang, Cayce Denton, Ian Finn, Amrita Ghosh, Ritu Gutpa, Margaret Latocha, Peter Lee, Richard Ma and Vinod Rao--have collaborated with others at Harvard University and MIT's Departments of Biology, Brain and Cognitive Sciences, Chemical Engineering, Mechanical Engineering, Electrical Engineering and Computer Science, and Materials Science and Engineering.

This research is supported by the US Army Research Office, the Office of Naval Research, the National Institutes of Health, Hercules Inc., the MIT UROP Office and the Whitaker Foundation.

A version of this article appeared in the September 1, 1999 issue of MIT Tech Talk (Volume 44, Number 4).