Hatching a well-planned business proposal to keep an egg from breaking may be a funny way to prove your business acumen, but participants in the Freshman Alumni Summer Internship Program (FASIP) were required to do just that in their final workshop of the semester.

The 27 freshmen were divided into three corporate teams and asked to create a special container to exhibit and ship a fossilized dinosaur egg -- actually a large egg-shaped ball of newspaper covered with masking tape -- for a fictional "Museum of Science."

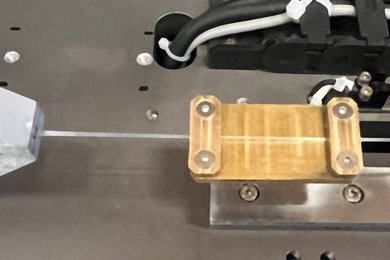

Company teams each designed and built prototype containers for the foot-long egg using cardboard, styrofoam, wire hangers, wooden dowels, cellophane wrap and paper cups. They purchased materials, rented factory space at $1,000 a day, costed out the final project (charging each member's labor at $16/hour), submitted a bid and, finally, tried to sell their product through a presentation to a mock board of directors.

And they did all that in just three hours.

"It was crazy in here for a while. There were students running from room to room in frenzied activity," said Marshall Hughes, program coordinator for FASIP.

Mr. Hughes and Professor of Anthropology Arthur Steinberg, a MacVicar Fellow and director of FASIP and the Integrated Studies Program (ISP), contrived the dinosaur egg game to help teach freshmen what it's like to work in teams in a corporate environment.

"We've held a series of workshops dealing with interviews and communications, memos and meetings, and the dynamics of the workplace," Professor Steinberg said. "What we wanted to do in the final workshop was put a lot of this together in a game that would simulate an on-the-job environment, with students working in teams to produce something, in hardly any time."

They set up two factories and a supply house in Building 16 classrooms, and required the corporate teams to do business with the managers of those entities. Rosalind Wood, administrative assistant to the provost, acted as owner of the factory space ("Rosalind Wood Enterprises"), and ISP lecturer Freddie Steinberg managed "Fred's Materials and Supplies." Other MIT staff served as company presidents to advise the students.

After a scant two hours of planning, building and preparing bids, teams began their formal presentations to the "board of directors" -- five MIT staff members and business writer David Warsh of The Boston Globe.

The first presentation was from "Applix," which has 100 full-time employees and was founded in 1947 by an MIT graduate, according to the students -- "an EECS type who was interested in humanities," said company spokesperson Eric Tseng.

The Applix prototype exhibition box came with its own shipping carton, a feature lacking in the other two prototypes. The box itself had a built-in GPS system, voltage converter and an alarm system. The exhibit box was "so state-of-the-art that some of the systems are still patent-pending," said Mr. Tseng.

The first remark during the Q&A session following his presentation brought laughter from the audience.

"It appears that the egg won't fit into that box," said a student from a competing company.

"The egg was still being uncovered from the Earth when we designed," so the prototype was not made to exact size, replied Mr. Tseng, without skipping a beat. "The outer rods of the prototype are expandable."

"Can you demonstrate the expand-ability function?" prodded the competitor.

"Next question," Mr. Tseng said.

At $47,000, the Applix container was the most expensive, but that didn't stop the board from choosing it. The other teams' designs were similarly high-tech, but each relied on a different mechanism for actually supporting the egg.

"Creative Design," billing itself as a three-year-old spinoff from Samsonite with nine employees, designed an EggSafe container made with bullet-proof glass and a steel frame, "allowing for maximum display surface. You can view the egg from all angles," said Elicia Anderson in her presentation. The price tag was $37,000.

"EggTransport Inc.," which has designed cases for the Russian government's Faberg��� eggs, priced its box at just $21,999. The company's prototype had copper rimming whose "color matches the egg's color to emphasize the egg," said Edward Keehr, company spokesperson.

But the board of directors placed their confidence in Applix, the oldest and most experienced company.

"A company that has worked with Frank Gehry gives us a great deal of confidence," said Diana Strange, director of special projects for the Alumni Association and chair of the mock board. "We're comforted that there was a mechanism for shipping as well as displaying the product. And we were impressed by your service contract and simple, straightforward design."

Each member of the winning team received "tradable stock in a local company," said Mr. Hughes as he presented Applix members with their stock: gift certificates for Toscanini's Ice Cream.

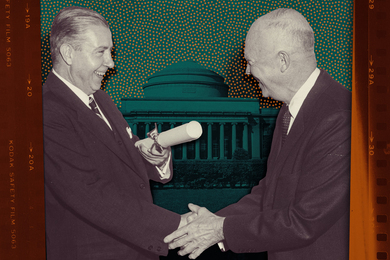

FASIP, which was initiated by Provost Joel Moses last fall (MIT Tech Talk, Nov. 12, 1997), is still in the pilot stages. This year it will place freshman interns in businesses owned or operated by alumni/ae in the Boston and San Francisco Bay areas, with the possibility of future geographic expansion.

The interns receive salaries from their employers and work closely with their alumni/ae mentors throughout the internship. Professor Steinberg, who believes in the importance of preparing students for the communications and socialization aspects of real-world employment, also requires students to write a paper about their experience and give an oral presentation in the fall.

Companies participating in the program this year include Teradyne, Inc., headed by Alexander d'Arbeloff (SB '49), chairman of the MIT Corporation and an enthusiastic supporter of FASIP. Others include Cabot Corp., Pratt and Whitney, Glowdog, SensAble Technologies, SMS Technologies, MRJ Technologies, Product Genesis, LCS Telegraphics and MIT's Technology Licensing Office.

A version of this article appeared in MIT Tech Talk on June 3, 1998.