Junli Hao was close to earning her MIT doctorate in chemical engineering this year when Covid-19 hit the United States — and forced universities including MIT to quickly de-densify. Hao suddenly found herself applying everything she’d learned to a major problem associated with the pandemic: the short supply of face masks and N95 respirators for medical personnel and other first responders.

For the past two months Hao, working closely with her advisor, Professor Gregory Rutledge, has used specialized equipment in the Rutledge lab to test the filtration properties and breathability of close to 100 types of masks that claim to be as effective as the N95 but do not have official certification from the U.S. National Institute for Occupational Safety and Health (NIOSH). These include different types of KN95 respirators, which are regulated by the Chinese government, and even a stockpile of N95 respirators that had expired.

To date, about one-third of the KN95s tested by Hao appear to meet or come close to the N95 standard. The results, which are listed on the Massachusetts Department of Public Health’s website, allow hospitals and other organizations to make better decisions on which masks and respirators to use, and under what conditions.

“The goal is to make sure that the masks and respirators being distributed are actually protecting our frontline responders. Ineffective masks could put them in danger,” says Hao, who grew up in Shenzhen, China, before coming to the United States to attend Rice University, where she earned her undergraduate degree.

She emphasizes, however, that the MIT tests do not replace certification by NIOSH, which currently has a backlog of requests due to national demand. The Rutledge lab, for example, does not have the capacity to test a full respirator, including its fit around the face. Hao only tests the materials the masks and respirators are made of, but the data she provides are key indicators of a device’s effectiveness.

In addition to testing existing masks and respirators, Hao is also analyzing the effectiveness of new materials being developed by various companies for personal protective equipment (PPE). The ultimate goal is to collect that information in a database that could aid work toward a better understanding of how these materials work and the effects of different compositions and manufacturing techniques on their effectiveness. Hao notes, however, that “right now we’re so slammed with testing” that the database will have to wait.

Relevant research

For almost five years, Hao has been studying the production and applications of electrospun nanofibers, fibers that are 1/100 the diameter of a human hair and created using an electric force. The focus of the first part of her thesis involves using those fibers in novel filters for the chemical separation of aerosols, tiny liquid or solid droplets suspended in the air.

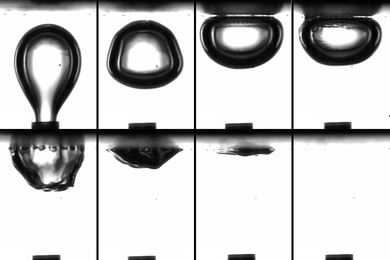

Since the coronavirus spreads via aerosols, Hao and Rutledge realized that her work and the equipment she uses could be of aid in the crisis. So Rutledge donated the services of his lab to the Massachusetts Manufacturing Emergency Response Team, an initiative aimed at quickly analyzing materials and products. Hao then adapted the Rutledge lab equipment to the testing in triplicate of small circular swatches of material from each type of mask.

“I would expose each material to aerosols with particle sizes around 75 nanometers, which is consistent with the NIOSH standard [for N95 testing], then determine each material’s efficiency, or how many of the particles it removed,” says Hao. She also analyzes a material’s breathability by characterizing its resistance to air flow.

Tackling challenges

Hao had to tackle a variety of challenges related to setting up the testing system. Among other things, since MIT was essentially shut down, she didn’t have access to certain resources. “We really had to just make do with what we had,” she says. And social distancing has had an impact on how she trains other students to conduct the tests.

That said, she feels that her MIT PhD training prepared her well. “Throughout my time at MIT I’ve learned a lot of problem-solving skills. I’ve also learned how to address problems under a time crunch, and I think that’s a very important life skill.” In addition, she emphasizes the support she’s received from Rutledge. “He has such integrity, and really cares about [his students’] personal development in addition to our research.”

MIT overall has “given me the opportunity to get involved in so many things in addition to science.” For example, Hao is currently co-chair of the MIT Graduate Student Council’s subcommittee on sustainability. She’s also vice president of Graduate Women in Chemical Engineering. In sum, she says, “I really like the people here. I feel inspired all the time and I’m always learning.”

After Hao receives her PhD — which she hopes will happen by December — she thinks she’ll go into industry. Specifically, she’d like to get into an industry related to sustainability. “I’d like to have a positive impact on the environment through my work.”

What’s been the best part of her work on the respirators? “I’m just really thankful to be able to help our frontline responders. I like to feel that I’m contributing.”