Bench-top automation in the lab can reduce variation in carbon nanotube growth, as well as enable better production of other nanomaterials, according to a research report by a team who originated the work at the University of Michigan and now reside at MIT.

Visiting graduate student Ryan Oliver and Associate Professor of Mechanical Engineering A. John Hart published their results in “Robofurnace: A semi-automated laboratory chemical vapor deposition system for high-throughput nanomaterial synthesis and process discovery” in Review of Scientific Instruments in November 2013.

Variations in equipment and operating procedures among laboratories spawn inconsistent outcomes in materials research. But consistent outcomes are necessary to maximize research throughput and translate materials processing knowledge successfully into production-scale systems. To manufacture carbon nanotubes (CNTs) on a large scale, it will be necessary to standardize methods and speed up production. Toward this end, Oliver and Hart developed Robofurnace, an automated chemical vapor deposition (CVD) furnace system that automates sample insertion and removal and uses motion of the furnace to achieve rapid heating and cooling.

Oliver says the reductions in variation in manual bench-top CVD reactor growth of CNTs can accelerate the research cycle. "Reducing the number of experiments necessary to draw a conclusion, that is where we hope for the advantage,” he says. “If you can reduce the variation, you can perform fewer experiments and be more confident in the results when you do claim you improved the material."

Robofurnace can handle 16 CVD experiments in 24 hours, bettering standard practice by at least four times. "All of these improvements mean we can answer more questions faster," Oliver says. A parametric study using Robofurnace boosted density of CNT forests grown in the Hart lab by at least 10 times over previously reported values in the same laboratory.

The Robofurnace article was chosen as an editor’s pick in Review of Scientific Instruments and was featured in Physics Today. The work was related to another group paper, “Statistical Analysis of Variation in Laboratory Growth of Carbon Nanotube Forests and Recommendations for Improved Consistency,” published in ACS Nano in March 2013. “Something unique about both of these is, in the carbon nanotube world, everybody wants to get the tallest, the densest and biggest, but this has been kind of an elephant in the room, and I think that’s why it’s appreciated,” says Oliver, whose background is in industrial engineering. “This is a problem for everybody, and the solution comes via a methodological approach to understand the growth of carbon nanotube forests.”

Oliver received his bachelor’s and master’s degrees in industrial and manufacturing systems engineering from the University of Texas at Arlington and will finish his PhD through the University of Michigan in August. "I'm very thankful to John for the opportunity to visit MIT and be a visiting scholar," Oliver says.

The Robofurnace project, which has its own website and Twitter feed, is being rebuilt at MIT with improved mechanics. Plans call for a new iteration of Robofurnace to be set up in the MIT mechanosynthesis labs by the end of April. Oliver expects to work with an undergraduate student on the project. “I think it will improve on capabilities we lacked in the first round by simplifying the system,” Oliver says. “It will be more robust. I'm also quite excited to see the website grow and collect and share data from Robofurnace and others via Twitter.”

Hart credits Oliver for leadership of the Robofurnace project. “The complexity is in the integration of everything and making it into a functional, reliable system,” Hart says. “Ryan built the vision for the system and recruited a team of students to build the first prototype.”

Hart didn’t file for a patent on the Robofurnace. “I’d rather make it an open-source set of hardware that people could build themselves,” he says.

Bench-top 'Robofurnace' automates chemical vapor deposition process.

Publication Date:

Caption:

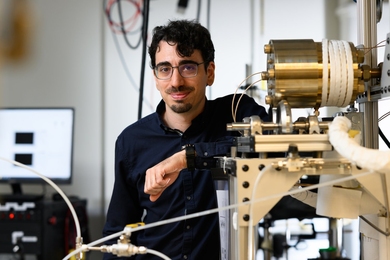

Visiting graduate student Ryan Oliver with a microscope. Oliver's projects under associate professor of mechanical engineering A. John Hart include the Robofurnace, an automated system for making carbon nanotube forests and studying their growth, and high-throughput manufacturing of polymer microstructures for biosensing.

Credits:

Photo: Denis Paiste/Materials Processing Center

Caption:

The Mechanosynthesis group includes visiting graduate student Ryan Oliver (left), A. John Hart, and postdoc associate Mostafa Bedewy.

Credits:

Photo: Denis Paiste/Materials Processing Center