Kelsey Stoerzinger, a materials science graduate student who is working with MIT Professor Yang Shao-Horn, is producing fundamental insights into the surface chemistry of transition metal oxides in catalytic oxygen reduction reactions.

Their work led to identification of a particular ionic state, Mn3+ (manganese with three lost electrons) as the active species for oxygen reduction on thin films of lanthanum manganese oxide (LMO) and lanthanum calcium strontium manganese oxide (La(Ca,Sr)MnO3). Their results were published in March 2013 in Energy and Environmental Science. "They were able to demonstrate conclusively that Mn3+, not Mn4+ or Mn2+, is the active species for ORR. They also revealed that the substrate can greatly alter the ORR activities of oxide films of a few nanometers in thickness by interfacial charge transfer," EES Development Editor Rowan Frame wrote in an April blog post. "Their findings are very important for the future design of nanostructured catalysts for electrochemical conversion and storage."

Controlling valence states

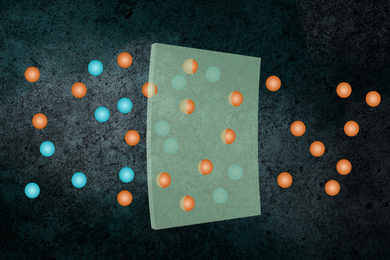

When an electrocatalytic reaction takes place in a device such as a battery or fuel cell, adsorption of the reactant to a catalyst transition metal center lowers the energetic cost to perform the reaction. Thus, the optimum metal-ion state of a catalyst must be determined. The researchers were able to control the number of electrons in manganese by introducing other elements such as strontium and calcium into the crystalline structure of the LMO, Stoerzinger said. "If I have something which has lanthanum and manganese, then my manganese will always want to be in a 3-plus state, more or less, but if I swap out some of my lanthanum for something like strontium, which has a different happy state – it has a different number of electrons that it likes to give up – then the valence state of my manganese, which is a little more flexible, will change," Stoerzinger said. "So by playing on these other elements, which are presumably inactive in our reaction, we can change the valence state of our active site, the manganese transition metal."

Shao-Horn addressed the importance of the study in an interview. Depending on the number of oxygen atoms in a manganese compound, the manganese atoms could be missing 2, 3 or 4 electrons (which are taken up by oxygen forming the metal-oxide compound.) "In this particular study, we show it is really manganese-3+ that are actually the active sites responsible for the high (oxygen reduction reaction) activity. We can actually change the valence state of the second metal from 2 to 3 or 3 to 2, from which you can change the manganese valence state either from 4 to 3 or 3 to 4 unambiguously because everything always has to add up to achieve electro neutrality," Shao-Horn said.

Although previous studies showed reactivity in manganese dioxide in bulk form, "We believe it's really the surface defects and the presence of manganese-3+ are responsible for the high activity and that, we think, is a significant and novel finding in terms of design of catalysts. If you want to develop a highly active catalyst, you do not want to make a manganese dioxide, because if you have surface activity, indeed, it's manganese-4+ with manganese dioxide. From this research, that surface would be completely inactive. That's where utilizing these well-defined atomically flat surfaces can provide this unambiguous determination of active states, or sites, or what's really responsible for the activity of oxygen reduction on manganese dioxide," Shao-Horn said.

Atomically flat films

The study used atomically flat thin films produced in the lab of National University of Singapore researcher T. Venkatesan, to whom Shao-Horn was introduced by MIT Professor Carl Thompson, the Stavros Salapatas Professor of Materials Science and Engineering and director of MIT Materials Processing Center.

Stoerzinger studies electrolytic catalysts in water-based solutions, using techniques such as Raman spectroscopy in Shao-Horn's Electrochemical Energy Lab at MIT to probe the surface of the thin films. She is also using facilities at the Lawrence Berkeley National Lab in Berkeley, Calif., to further her research. "The systems that I work with are based on technologies which are in a humid environment, they're aqueous technologies," Stoerzinger said. Spectroscopy lets her examine what the surface is like and how it reacts with water under near realistic conditions. The hope is to uncover the key ingredients of the active site responsible for the catalytic activity.

"In these well-controlled systems, we have a better idea what our surface is like so we can achieve better fundamental understanding of our reaction, but then you would want to in a real application to put these into something with higher surface area, so a nano-sized powder or something like that," she said. Insight from model surfaces can guide the design of highly active catalysts, the morphologies of which can be engineered for systems-level application.

Stoerzinger's work with oxides made out of earth abundant elements holds promise for fuel cells, for metal air batteries and electrochemical photo-induced reactions.

Their work led to identification of a particular ionic state, Mn3+ (manganese with three lost electrons) as the active species for oxygen reduction on thin films of lanthanum manganese oxide (LMO) and lanthanum calcium strontium manganese oxide (La(Ca,Sr)MnO3). Their results were published in March 2013 in Energy and Environmental Science. "They were able to demonstrate conclusively that Mn3+, not Mn4+ or Mn2+, is the active species for ORR. They also revealed that the substrate can greatly alter the ORR activities of oxide films of a few nanometers in thickness by interfacial charge transfer," EES Development Editor Rowan Frame wrote in an April blog post. "Their findings are very important for the future design of nanostructured catalysts for electrochemical conversion and storage."

Controlling valence states

When an electrocatalytic reaction takes place in a device such as a battery or fuel cell, adsorption of the reactant to a catalyst transition metal center lowers the energetic cost to perform the reaction. Thus, the optimum metal-ion state of a catalyst must be determined. The researchers were able to control the number of electrons in manganese by introducing other elements such as strontium and calcium into the crystalline structure of the LMO, Stoerzinger said. "If I have something which has lanthanum and manganese, then my manganese will always want to be in a 3-plus state, more or less, but if I swap out some of my lanthanum for something like strontium, which has a different happy state – it has a different number of electrons that it likes to give up – then the valence state of my manganese, which is a little more flexible, will change," Stoerzinger said. "So by playing on these other elements, which are presumably inactive in our reaction, we can change the valence state of our active site, the manganese transition metal."

Shao-Horn addressed the importance of the study in an interview. Depending on the number of oxygen atoms in a manganese compound, the manganese atoms could be missing 2, 3 or 4 electrons (which are taken up by oxygen forming the metal-oxide compound.) "In this particular study, we show it is really manganese-3+ that are actually the active sites responsible for the high (oxygen reduction reaction) activity. We can actually change the valence state of the second metal from 2 to 3 or 3 to 2, from which you can change the manganese valence state either from 4 to 3 or 3 to 4 unambiguously because everything always has to add up to achieve electro neutrality," Shao-Horn said.

Although previous studies showed reactivity in manganese dioxide in bulk form, "We believe it's really the surface defects and the presence of manganese-3+ are responsible for the high activity and that, we think, is a significant and novel finding in terms of design of catalysts. If you want to develop a highly active catalyst, you do not want to make a manganese dioxide, because if you have surface activity, indeed, it's manganese-4+ with manganese dioxide. From this research, that surface would be completely inactive. That's where utilizing these well-defined atomically flat surfaces can provide this unambiguous determination of active states, or sites, or what's really responsible for the activity of oxygen reduction on manganese dioxide," Shao-Horn said.

Atomically flat films

The study used atomically flat thin films produced in the lab of National University of Singapore researcher T. Venkatesan, to whom Shao-Horn was introduced by MIT Professor Carl Thompson, the Stavros Salapatas Professor of Materials Science and Engineering and director of MIT Materials Processing Center.

Stoerzinger studies electrolytic catalysts in water-based solutions, using techniques such as Raman spectroscopy in Shao-Horn's Electrochemical Energy Lab at MIT to probe the surface of the thin films. She is also using facilities at the Lawrence Berkeley National Lab in Berkeley, Calif., to further her research. "The systems that I work with are based on technologies which are in a humid environment, they're aqueous technologies," Stoerzinger said. Spectroscopy lets her examine what the surface is like and how it reacts with water under near realistic conditions. The hope is to uncover the key ingredients of the active site responsible for the catalytic activity.

"In these well-controlled systems, we have a better idea what our surface is like so we can achieve better fundamental understanding of our reaction, but then you would want to in a real application to put these into something with higher surface area, so a nano-sized powder or something like that," she said. Insight from model surfaces can guide the design of highly active catalysts, the morphologies of which can be engineered for systems-level application.

Stoerzinger's work with oxides made out of earth abundant elements holds promise for fuel cells, for metal air batteries and electrochemical photo-induced reactions.