Controlling the way liquids spread across a surface is important for a wide variety of technologies, including DNA microarrays for medical research, inkjet printers and digital lab-on-a-chip systems. But until now, the designers of such devices could only control how much the liquid would spread out over a surface, not which way it would go.

New research from mechanical engineers at MIT has revealed a new approach that, by creating specific kinds of tiny structures on a material’s surface, can make a droplet spread only in a single direction.

A report on the new work, by Esther and Harold E. Edgerton Assistant Professor of Mechanical Engineering Evelyn N. Wang and graduate students Kuang-Han Chu and Rong Xiao, was published on March 28 in the journal Nature Materials.

The system Wang and her team developed is completely passive, based on producing a textured surface with tiny pillars shaped in specific ways to propel liquid in one direction and restrict its movement in others. Once the surface is prepared, no mechanical or electrical controls are needed to propel the liquid in the desired direction, and a droplet placed at any point on the surface will always spread the same way.

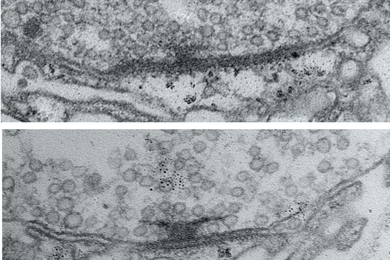

It’s just the shapes on the surface that control how the drops spread, rather than the particular materials used, Wang says. The chips used for testing were made at the MIT Microsystems Technology Lab by etching a silicon wafer surface to produce a grid of tiny pillars, which then were selectively coated with gold on one side to make the pillars bend in one direction. To prove that the effect was caused just by the bent shapes rather than some chemical process involving the silicon and gold, the researchers, with the help of Professor Karen Gleason’s group in the Department of Chemical Engineering, then coated the surface with a thin layer of a polymer so that the water would only come in contact with a single type of material. The pillars are all curved in one direction, and cause the liquid to move in that direction.

“Nobody had really studied this kind of geometry, because it’s hard to fabricate,” Wang says.

Wang explains that while this work is still early-stage basic research, in principle such systems could be used for a wide variety of applications. For example, it could provide new ways to manipulate biological molecules on the surface of a chip, for various testing and measurement systems. It might be used in desalination systems to help direct water that condenses on a surface toward a collection system. Or it might allow more precise control of cooling liquids on a microchip, directing the coolant toward specific hotspots rather than letting them spread out over the whole surface.

“It’s a big deal to be able to cool local hotspots on a chip,” Wang says, especially as the components on a chip continue to get smaller and thermal management becomes ever more critical. The research was funded in part by the National Science Foundation, DARPA, and Northrup Grumman.

Mark Shannon, professor of mechanical science and engineering at the University of Illinois, Urbana-Champaign, agrees that this method might be further developed for a variety of applications, including biomedical lab-on-a-chip systems for the detection of specific biomolecules in blood, for example. “Droplet manipulation has been heavily developed for moving samples from station to station for different analysis steps,” he says, and this new method might provide a useful way to do that with minimal energy requirements, but to do so will require the ability to create multiple regions on a surface that propel the liquid in different directions for each stage. “This research will help enable these unit operations,” he says, in combination with related research currently being carried out in other places.

Howard Stone, professor of mechanical and aerospace engineering at Princeton University, who was not involved in this research, says researchers have taken several approaches to surface patterning and control in recent years, some inspired by nature and some by materials applications. “This research advance for one-dimensional asymmetric spreading is a nice addition to the toolbox for surface patterning to control liquid spreading,” he says.

New research from mechanical engineers at MIT has revealed a new approach that, by creating specific kinds of tiny structures on a material’s surface, can make a droplet spread only in a single direction.

A report on the new work, by Esther and Harold E. Edgerton Assistant Professor of Mechanical Engineering Evelyn N. Wang and graduate students Kuang-Han Chu and Rong Xiao, was published on March 28 in the journal Nature Materials.

The system Wang and her team developed is completely passive, based on producing a textured surface with tiny pillars shaped in specific ways to propel liquid in one direction and restrict its movement in others. Once the surface is prepared, no mechanical or electrical controls are needed to propel the liquid in the desired direction, and a droplet placed at any point on the surface will always spread the same way.

It’s just the shapes on the surface that control how the drops spread, rather than the particular materials used, Wang says. The chips used for testing were made at the MIT Microsystems Technology Lab by etching a silicon wafer surface to produce a grid of tiny pillars, which then were selectively coated with gold on one side to make the pillars bend in one direction. To prove that the effect was caused just by the bent shapes rather than some chemical process involving the silicon and gold, the researchers, with the help of Professor Karen Gleason’s group in the Department of Chemical Engineering, then coated the surface with a thin layer of a polymer so that the water would only come in contact with a single type of material. The pillars are all curved in one direction, and cause the liquid to move in that direction.

“Nobody had really studied this kind of geometry, because it’s hard to fabricate,” Wang says.

Wang explains that while this work is still early-stage basic research, in principle such systems could be used for a wide variety of applications. For example, it could provide new ways to manipulate biological molecules on the surface of a chip, for various testing and measurement systems. It might be used in desalination systems to help direct water that condenses on a surface toward a collection system. Or it might allow more precise control of cooling liquids on a microchip, directing the coolant toward specific hotspots rather than letting them spread out over the whole surface.

“It’s a big deal to be able to cool local hotspots on a chip,” Wang says, especially as the components on a chip continue to get smaller and thermal management becomes ever more critical. The research was funded in part by the National Science Foundation, DARPA, and Northrup Grumman.

Mark Shannon, professor of mechanical science and engineering at the University of Illinois, Urbana-Champaign, agrees that this method might be further developed for a variety of applications, including biomedical lab-on-a-chip systems for the detection of specific biomolecules in blood, for example. “Droplet manipulation has been heavily developed for moving samples from station to station for different analysis steps,” he says, and this new method might provide a useful way to do that with minimal energy requirements, but to do so will require the ability to create multiple regions on a surface that propel the liquid in different directions for each stage. “This research will help enable these unit operations,” he says, in combination with related research currently being carried out in other places.

Howard Stone, professor of mechanical and aerospace engineering at Princeton University, who was not involved in this research, says researchers have taken several approaches to surface patterning and control in recent years, some inspired by nature and some by materials applications. “This research advance for one-dimensional asymmetric spreading is a nice addition to the toolbox for surface patterning to control liquid spreading,” he says.